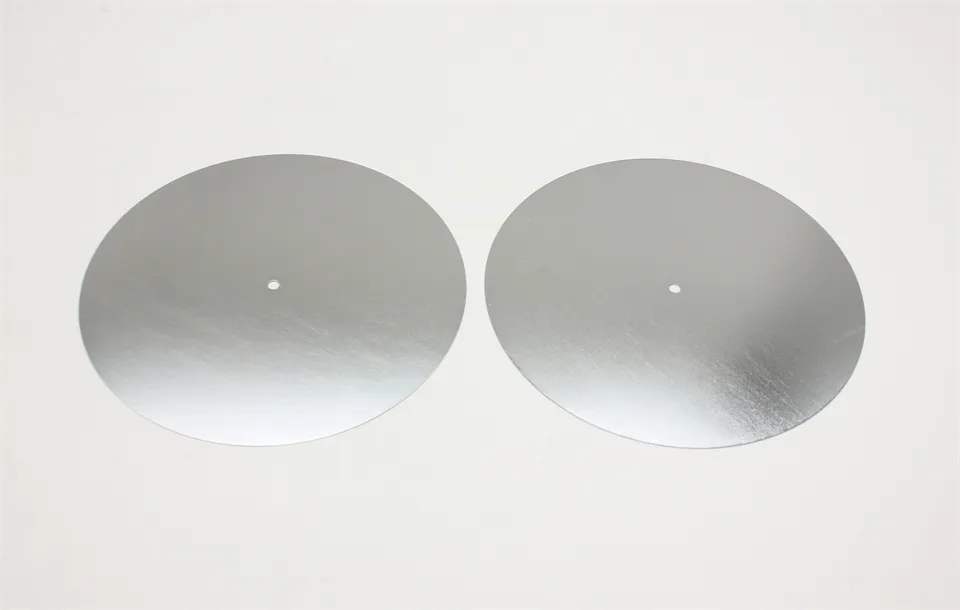

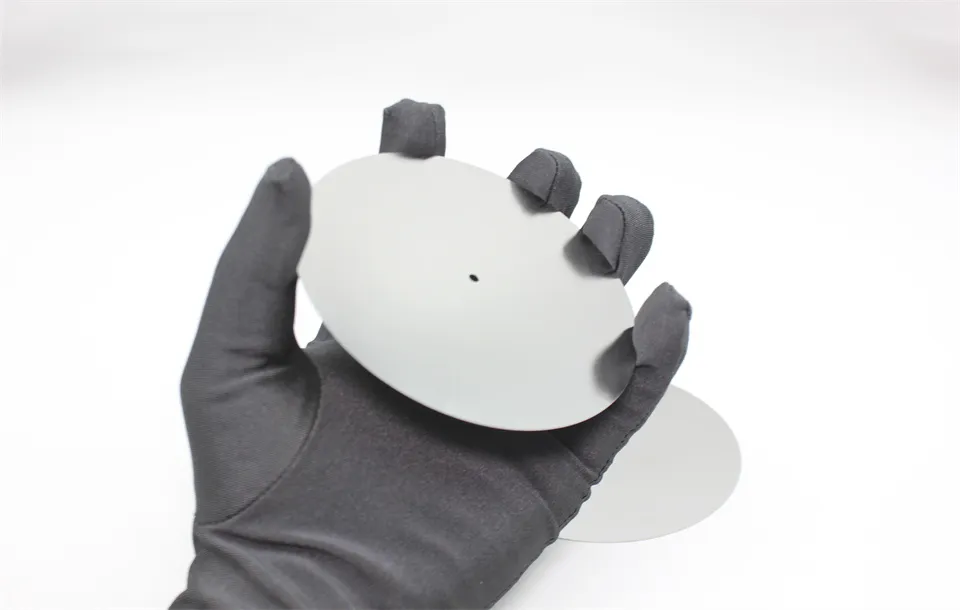

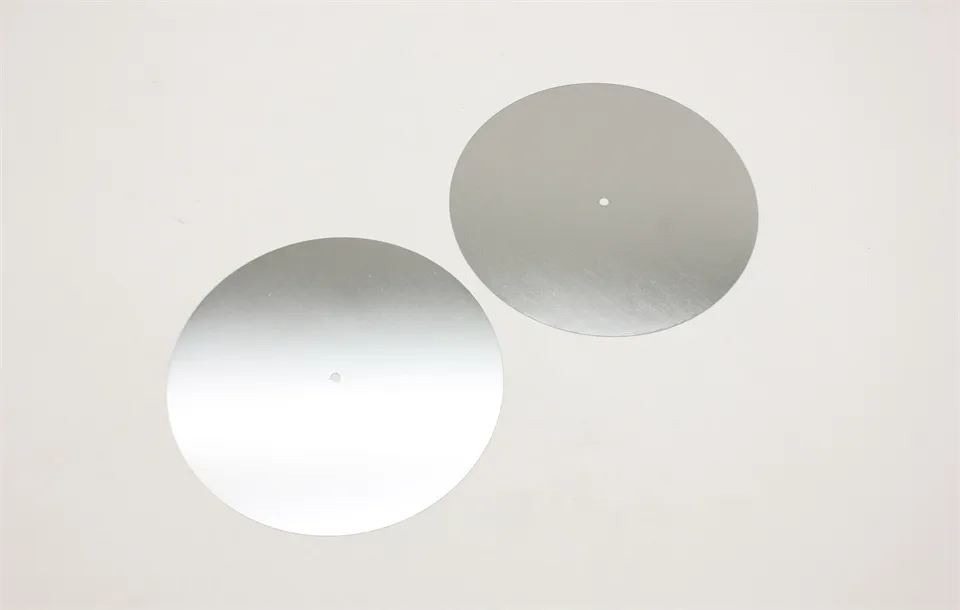

High Purity Polished Tungsten Wafer

| Payment Type: | T/T |

| Incoterm: | FOB,CIF,EXW,FCA,Express Delivery |

| Min. Order: | 2 Kilogram |

| Transportation: | Ocean,Air,Express |

Attributes

Model No.: JDTG-TW-001

Brand: ZZJD

Place Of Origin: China

Size: Support customization Length&Diameter

Material: Tungsten

PACKAGING & DELIVERY

Package Type : Standard export packing

DESCRIPTION

Tungsten alloy wafers are specialized materials used in various high-tech applications, particularly in the semiconductor and electronics industries. Here are some key points about tungsten alloy wafers:

1. Composition: Tungsten alloys typically consist of tungsten combined with other metals like nickel, iron, or copper.

2. Properties:

- High melting point (up to 3422°C)

- Excellent thermal conductivity

- Good electrical conductivity

- High density and strength

- Resistance to corrosion and wear

3. Applications of Tungsten wafer:

- Semiconductor manufacturing equipment

- X-ray targets

- Radiation shielding

- High-temperature furnace components

- Military and aerospace parts

4. Manufacturing process:

- Powder metallurgy techniques

- Sintering at high temperatures

- Precision grinding and polishing to achieve desired thickness and flatness

5. Specifications:

- Typically available in thicknesses ranging from 0.1 mm to several millimeters

- Diameter can vary, but common sizes include 100mm, 150mm, and 200mm

6. Surface finish:

- Can be polished to very smooth finishes (e.g., <10 nm Ra)

7. Customization:

- Can be produced in various shapes and sizes based on specific application requirements

8. Quality control:

- Strict dimensional tolerances and material consistency are maintained

9. Cost:

- Generally more expensive than standard metal wafers due to the specialized nature of tungsten alloys

10. Research and development:

- Ongoing work to improve properties and develop new applications for these materials

EN

EN AR

AR FR

FR DE

DE HI

HI IT

IT JA

JA KO

KO PT

PT RU

RU ES

ES ID

ID LV

LV VI

VI HU

HU MS

MS GA

GA BE

BE YI

YI EU

EU