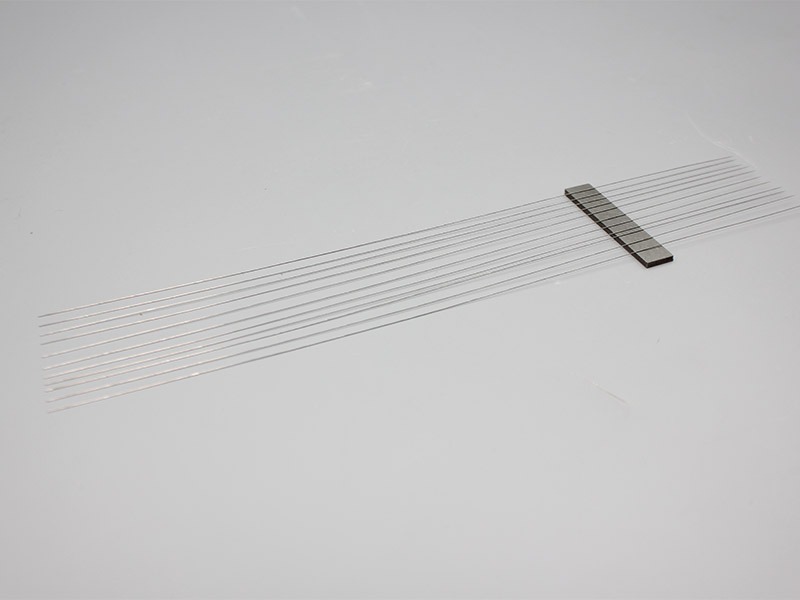

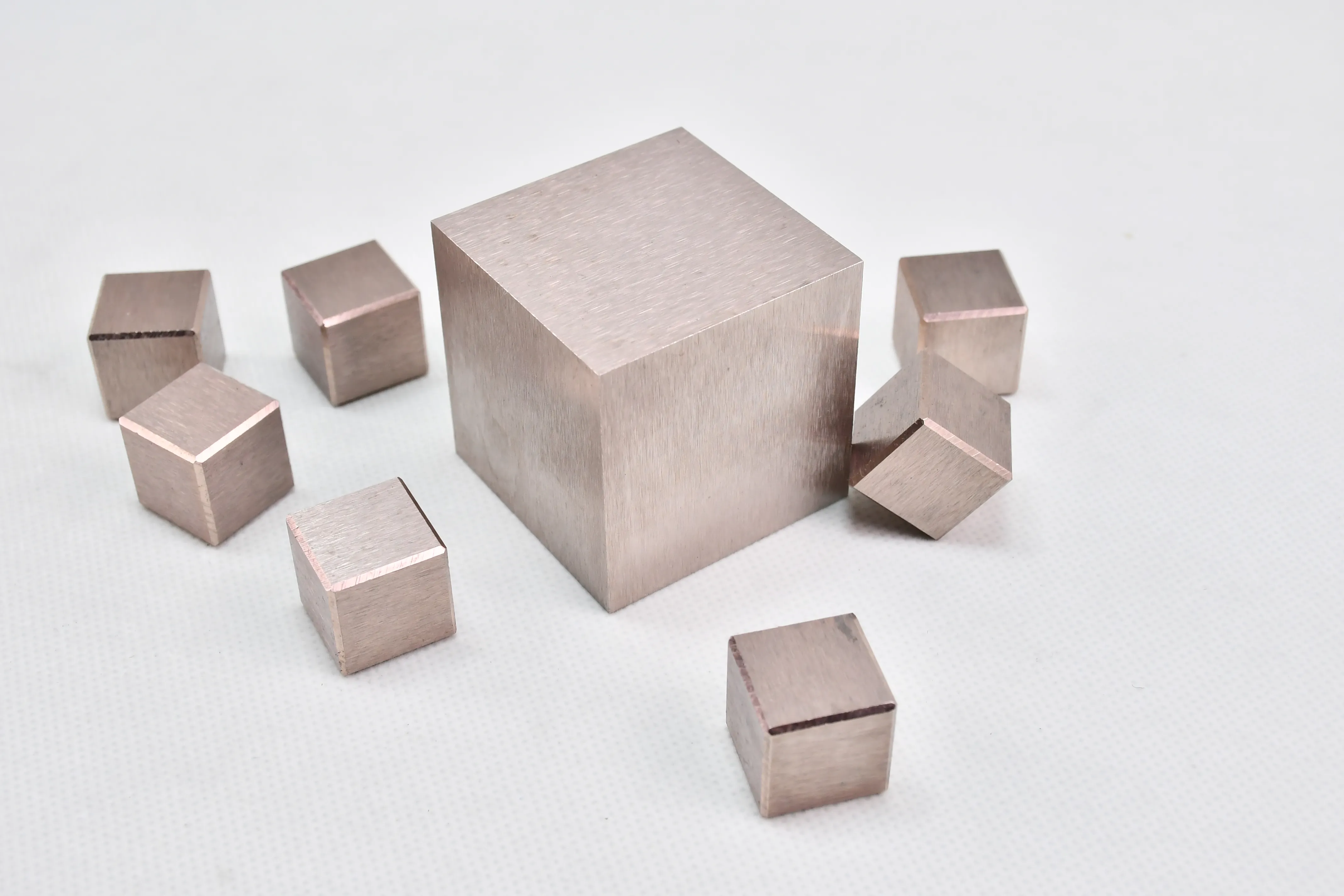

China tungsten heavy alloy plates has become an important material in industries manufacturing compact and lightweight yet robust items. Its tensile strength and relative flexibility provide good performance in aerospace devices and instruments, where precision is paramount. The heat-resistance and low thermal expansion of the alloy facilitate operational precision while minimizing deformation. It is also considered a high-performance option in rotating machinery experiencing high energy-translation speeds and mechanical vibration.

Because of density and strength, China tungsten heavy alloy plates are well-suited for precision machinery applications requiring precise balancing and vibration control. Examples include flywheels and dynamic dampers, as well as automotive applications for crankshaft weights or other components. {Keywords} absorb vibration, extends the life of machines, and improves performance when used in high speed operational conditions.

As sustainability becomes a priority, the future of China tungsten heavy alloy plates will be related to effective recycling and cleaner production methods. Researchers are focused on identifying ways to recover tungsten from industrial waste while maintaining alloy integrity. In addition, alloy will factor into the design of lightweight energy systems and smart infrastructure requiring mass and strength.

The life of China tungsten heavy alloy plates is consistent with care and maintenance. Do not drop or strike it against hard surfaces, as even minor impressions will impact the balance and performance of the China tungsten heavy alloy plates. Transport and store in tightly sealed containers to protect China tungsten heavy alloy plates from humidity and airborne contaminants.

Due to its moderately high melting point combined with toughness, China tungsten heavy alloy plates performs well under extreme conditions. Commonly it has uses in radiation shielding, medical devices, and military hardware. The strength and stability provided from China tungsten heavy alloy plates make it an obvious choice for precision applications.

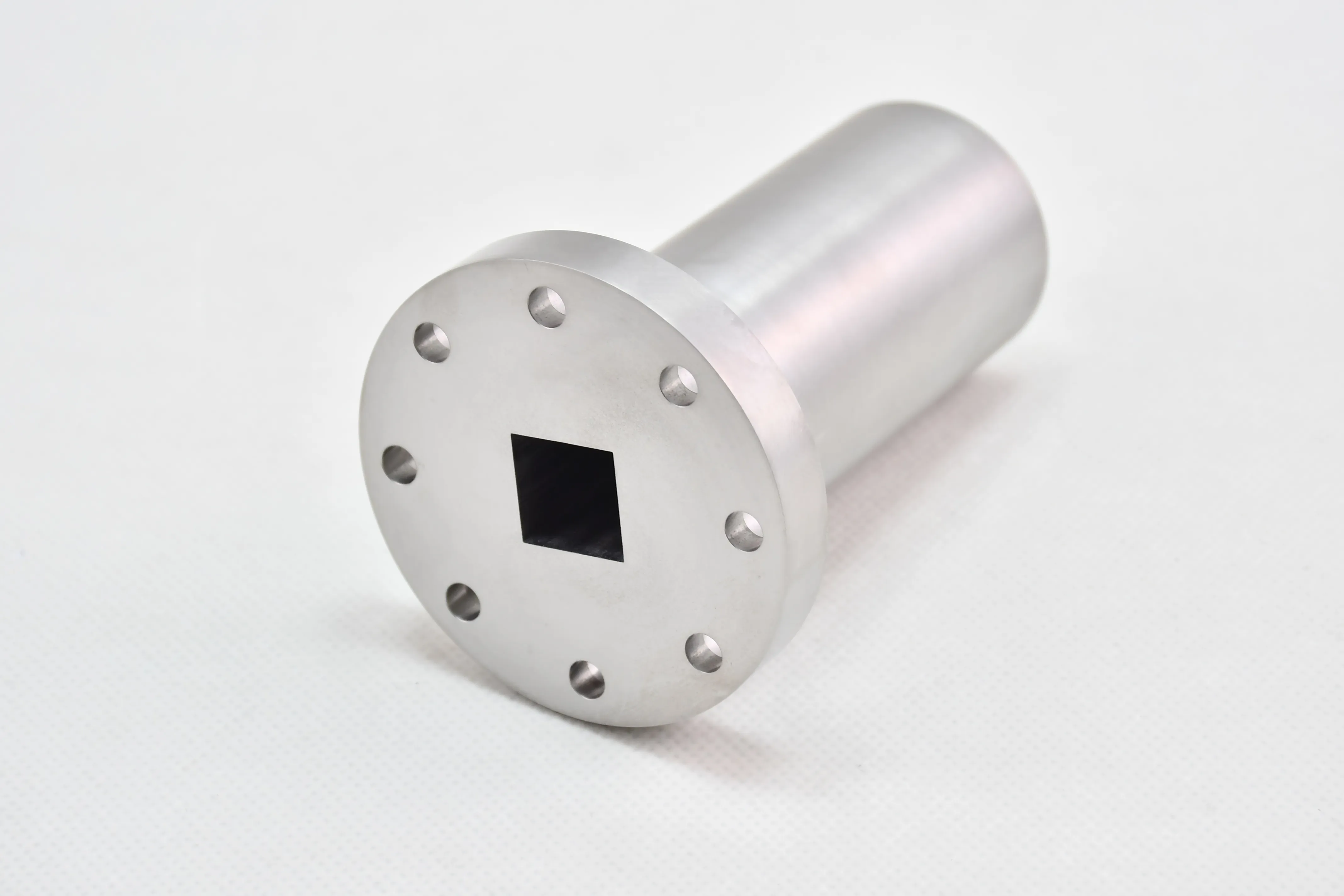

Q: How is Tungsten heavy alloy used in oil and gas exploration? A: It serves as a key material for counterweights, drilling tools, and downhole equipment due to its density and wear resistance. Q: What maintenance practices help preserve Tungsten heavy alloy components? A: Regular cleaning, controlled storage, and protection from moisture help prevent oxidation and extend service life. Q: Why does Tungsten heavy alloy perform well in vibration control? A: Its density and internal damping capacity reduce oscillations in precision machinery and aerospace systems. Q: What machining techniques are best for Tungsten heavy alloy? A: CNC milling, grinding, and electrical discharge machining are commonly used for shaping Tungsten heavy alloy with precision. Q: How does Tungsten heavy alloy support environmental sustainability? A: It replaces toxic lead in many applications while offering durability and recyclability for eco-friendly production cycles.

What I love about the tungsten jig is how fast it sinks and how naturally it moves in the water.

The tungsten jig feels incredibly durable — I’ve caught dozens of fish, and it still looks new.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

We are a machining parts supplier seeking tungsten heavy alloy rods for precision components. Kindly...

I’m interested in your tungsten jig models used for saltwater fishing. Please share your catalog a...

Copyright © Zhuzhou Jiuding Metal Technology Co., Ltd. All Rights Reserved