The heavy composition of China tungsten heavy alloy price per kg usually contributes to excellent mechanical equilibrium and also energy transfer capability. The there being a good microstructure the material becomes not only more durable but less prone to failing even if the demand is for cyclic loading. Industries count on its stability for the making of gyroscopes, flywheels, and precision molds. The mix of density and non-corrosive nature makes China tungsten heavy alloy price per kg the right choice for the locations where the operations are either in the sea or at high temperatures, thus, the performance continuity for the demanding industrial tasks is assured.

Because of density and strength, China tungsten heavy alloy price per kg are well-suited for precision machinery applications requiring precise balancing and vibration control. Examples include flywheels and dynamic dampers, as well as automotive applications for crankshaft weights or other components. {Keywords} absorb vibration, extends the life of machines, and improves performance when used in high speed operational conditions.

In the future, China tungsten heavy alloy price per kg will find applications that include AI-assisted design, where automated manufacturing will provide precise customization, desirable for aerospace, robotics, and medical devices. It will be a valuable component in systems that depend on especially consistent performance in severe thermal and mechanical conditions.

The life of China tungsten heavy alloy price per kg is consistent with care and maintenance. Do not drop or strike it against hard surfaces, as even minor impressions will impact the balance and performance of the China tungsten heavy alloy price per kg. Transport and store in tightly sealed containers to protect China tungsten heavy alloy price per kg from humidity and airborne contaminants.

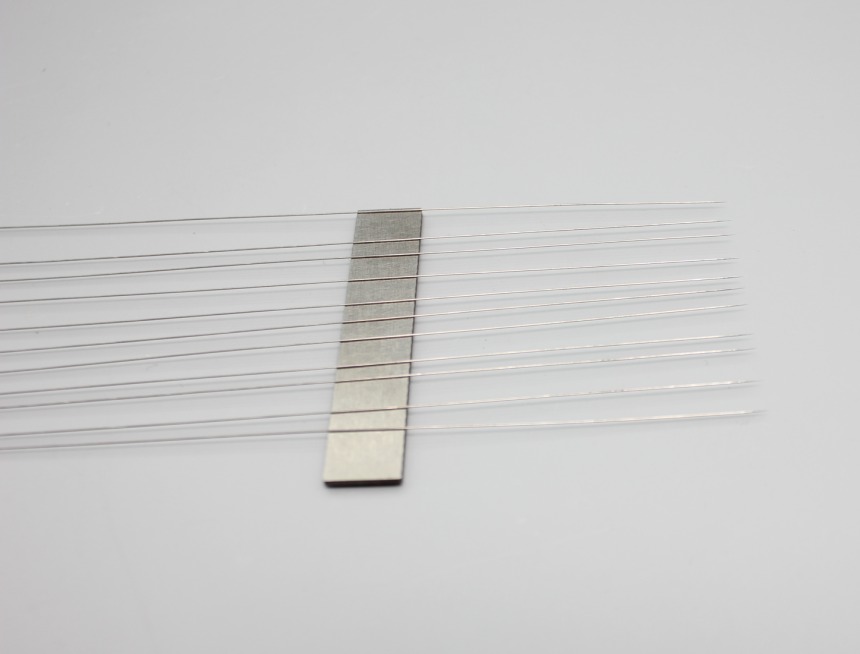

China tungsten heavy alloy price per kg is specifically designed for high performance applications, combining hardness with good machinability. Common applications include for counter weights, ballistic applications, and vibration damping structures. The consistent physical properties of the material provide a high level of precision and durability in a final product.

Q: What makes Tungsten heavy alloy essential in engineering applications? A: Tungsten heavy alloy is essential because of its exceptional density, hardness, and thermal stability, making it reliable for use in high-performance mechanical and structural components. Q: How is Tungsten heavy alloy produced? A: It is made through powder metallurgy, where tungsten powder is blended with nickel, iron, or copper and sintered at high temperatures to form a compact, durable alloy. Q: Why is Tungsten heavy alloy suitable for aerospace industries? A: Its superior weight distribution and resistance to thermal stress make it perfect for use in counterbalances, rotor systems, and aircraft control components. Q: Can Tungsten heavy alloy be machined easily? A: While it is very dense and hard, it can be precisely machined using specialized tools designed for high-strength materials. Q: In which fields is Tungsten heavy alloy commonly applied? A: It is widely used in defense, medical imaging, oil drilling, aerospace, and industrial balancing systems.

The Tungsten heavy alloy provides solid consistency in production; every piece meets our exact requirements.

The Tungsten heavy alloy handles extreme pressure and heat better than most metals I’ve used.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

We are interested in tungsten heavy alloy cylinders for kinetic energy applications. Could you send ...

We are looking for high-density tungsten jig for our upcoming fishing gear line. Could you please se...

Copyright © Zhuzhou Jiuding Metal Technology Co., Ltd. All Rights Reserved