Intended for engineering purposes requiring high performance, Jiuding pure tungsten cube offers structural strength when there are density and weight restrictions. Its density facilitates good energy absorption and stability after repeated cycles of stress while demonstrating exceptional performance in counterweights, balancing devices, and damping devices. In addition, Jiuding pure tungsten cube is resistant to corrosion and oxidation, contributing to a long service life in a wet or chemically exposed environment.

Within the healthcare and medical field, Jiuding pure tungsten cube enjoys a wide application in shielding against radiation and as counterbalance configurations. Safety is critical in diagnosis equipment and groundbreaking technologies such as linear accelerators and gamma cameras. The aforementioned density allows for a smaller and lighter component, without sacrificing protection, which is a key driver of advanced technologies in modern healthcare applications.

In the following years expect a confluence of Jiuding pure tungsten cube with advanced composites for hybrid engineered materials. The hybrids will provide flexibility, corrosion resistance and weight reduction benefits. In addition, as industries look for stable and energy absorbing materials, the role of alloy in electric mobility and autonomous vehicles will grow.

Good maintenance of Jiuding pure tungsten cube ensures durable performance in extreme conditions. Periodically inspect mechanical joint and contact areas to detect early wear. In instances when oxidation has formed, buff the appearace with a mild abrasive pad. You can expect the oxidation to lose its unwanted appearance, but the performance of the Jiuding pure tungsten cube will not be adversely affected.

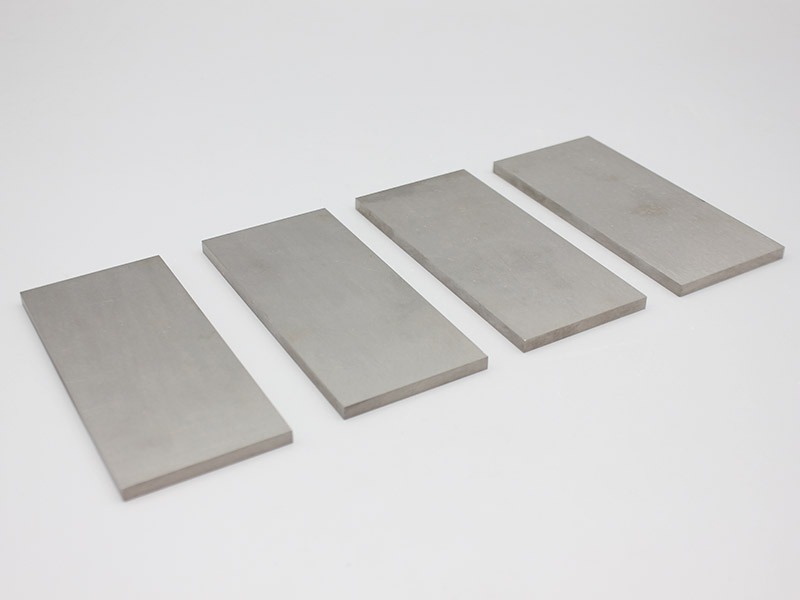

Jiuding pure tungsten cube is specifically designed for applications where there is mass that needs to fit into compact areas, while maintaining mechanical strength. It provides excellent wear resistance and thermal stability making it suitable for use as aerospace balancing parts or molds, and in heavy engineering equipment. The dense material will ensure that there is maximum efficiency and reliability in process.

Q: How is Tungsten heavy alloy used in oil and gas exploration? A: It serves as a key material for counterweights, drilling tools, and downhole equipment due to its density and wear resistance. Q: What maintenance practices help preserve Tungsten heavy alloy components? A: Regular cleaning, controlled storage, and protection from moisture help prevent oxidation and extend service life. Q: Why does Tungsten heavy alloy perform well in vibration control? A: Its density and internal damping capacity reduce oscillations in precision machinery and aerospace systems. Q: What machining techniques are best for Tungsten heavy alloy? A: CNC milling, grinding, and electrical discharge machining are commonly used for shaping Tungsten heavy alloy with precision. Q: How does Tungsten heavy alloy support environmental sustainability? A: It replaces toxic lead in many applications while offering durability and recyclability for eco-friendly production cycles.

I’ve used the tungsten jig for months, and its weight balance makes it super easy to control even in deep spots.

I appreciate that Tungsten heavy alloy is non-toxic yet just as heavy and stable as lead — a smart upgrade.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

Could you provide your latest price list and production capacity for tungsten heavy alloy bars? We p...

Could you provide info about your heavy-duty tungsten jig types suitable for deep-sea fishing? Looki...

Copyright © Zhuzhou Jiuding Metal Technology Co., Ltd. All Rights Reserved