The quality of Jiuding tungsten heavy alloys specifications is not just versatile; it is also strong and dense at the same time, which enables it to be efficiently used in small spaces. Its production involves merging tungsten with either nickel and iron or copper, resulting in a material that is rugged as well as easy to machine. This alloy possesses all the necessary features required in aerospace, defense, and power generation industries. Its precise weight distribution properties additionally open up the manufacture of counterweights, radiation shields, and high-impact tools that require constantly dependable quality.

Jiuding tungsten heavy alloys specifications has proven widely utilized in the defense and ballistics sector. Its compact mass and hardness permit penetrators, kinetic rods, and fragmentation cores to be made. Each component works using Jiuding tungsten heavy alloys specifications for greater kinetic energy transfer and penetration power. Each component of a munitions system must perform effectively and reliably under military requests.

As sustainability becomes a priority, the future of Jiuding tungsten heavy alloys specifications will be related to effective recycling and cleaner production methods. Researchers are focused on identifying ways to recover tungsten from industrial waste while maintaining alloy integrity. In addition, alloy will factor into the design of lightweight energy systems and smart infrastructure requiring mass and strength.

The life of Jiuding tungsten heavy alloys specifications is consistent with care and maintenance. Do not drop or strike it against hard surfaces, as even minor impressions will impact the balance and performance of the Jiuding tungsten heavy alloys specifications. Transport and store in tightly sealed containers to protect Jiuding tungsten heavy alloys specifications from humidity and airborne contaminants.

Jiuding tungsten heavy alloys specifications is specifically designed for applications where there is mass that needs to fit into compact areas, while maintaining mechanical strength. It provides excellent wear resistance and thermal stability making it suitable for use as aerospace balancing parts or molds, and in heavy engineering equipment. The dense material will ensure that there is maximum efficiency and reliability in process.

Q: What are the key mechanical properties of Tungsten heavy alloy? A: Tungsten heavy alloy offers high tensile strength, superior hardness, and outstanding resistance to fatigue, ensuring reliability in harsh environments. Q: How does Tungsten heavy alloy perform under extreme heat? A: It retains structural integrity and strength even at elevated temperatures, making it suitable for high-temperature engineering tasks. Q: Why is Tungsten heavy alloy favored for radiation shielding? A: Its high atomic mass and density allow it to effectively block radiation while maintaining structural strength. Q: Is Tungsten heavy alloy environmentally friendly? A: Yes, it is non-toxic and can be recycled efficiently, making it a sustainable material for long-term industrial use. Q: What are the typical compositions of Tungsten heavy alloy? A: It typically contains 90–98% tungsten combined with nickel, copper, or iron to enhance ductility and machinability.

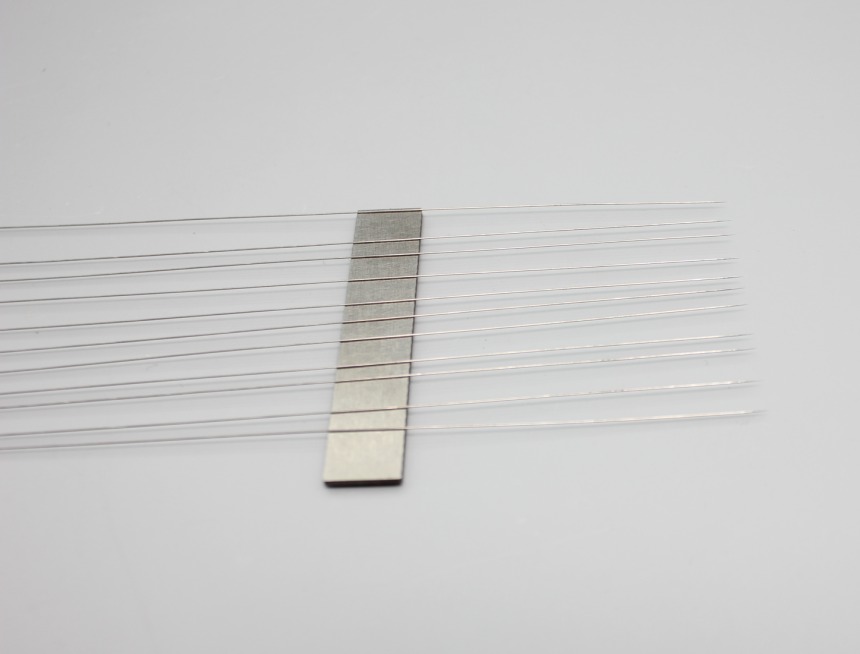

The tungsten jig performs great in both saltwater and freshwater; it doesn’t rust or wear out easily.

The Tungsten heavy alloy handles extreme pressure and heat better than most metals I’ve used.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

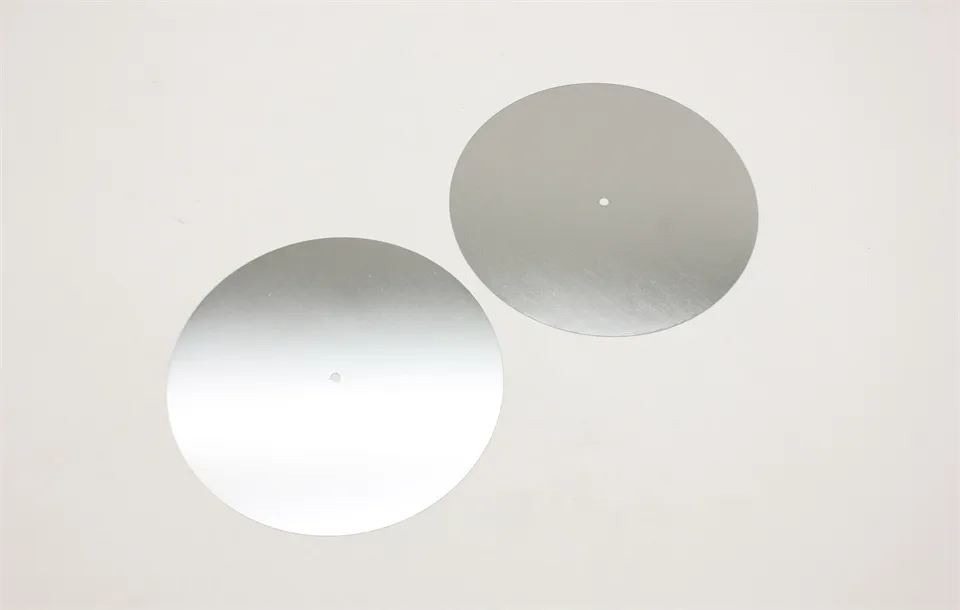

We need tungsten heavy alloy plates for counterweight applications. Please share available thickness...

I’m interested in your tungsten jig models used for saltwater fishing. Please share your catalog a...

Copyright © Zhuzhou Jiuding Metal Technology Co., Ltd. All Rights Reserved