alloying of tungsten manufacturer are concentrating on the production of tungsten heavy alloys that deliver the highest mechanical stability and the most uniform density. The alloys, in turn, have high resistance to wear, oxidation, and deformation. Under the conditions of advanced powder metallurgy and vacuum sintering, alloying of tungsten manufacturer obtain the highest accuracy in weight control and obtain the uniformity of the material. The aforementioned characteristics are the reason why their alloys are preferred in precision components for defense, aerospace, and industrial manufacturing.

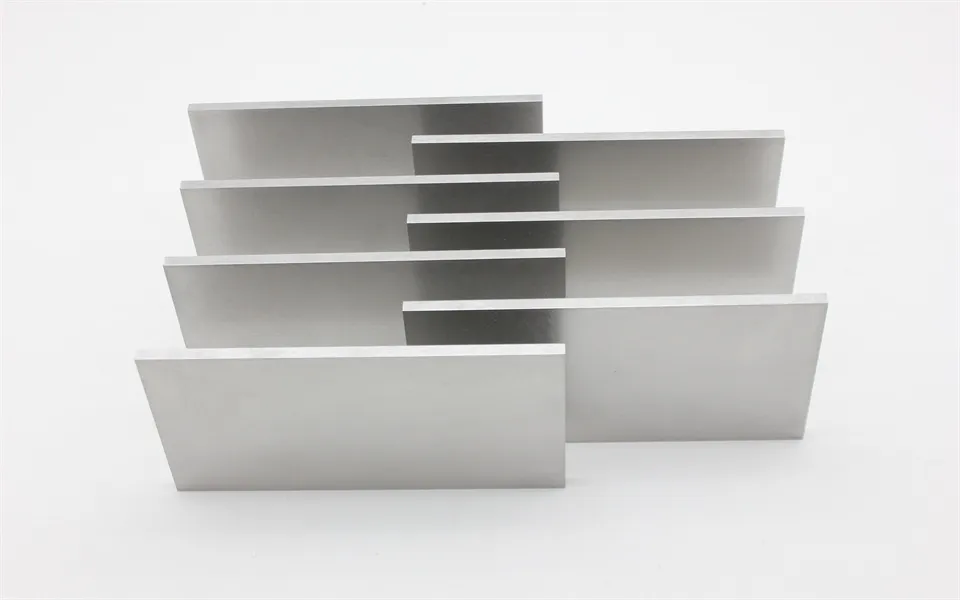

alloying of tungsten manufacturer give tungsten heavy alloys that have major applications in industries where high density and strength are needed. These materials can be found in the form of counterweights, as in for airplanes, helicopters in use and precision machinery. The other applications include kinetic energy penetrators, balancing systems, and radiation shielding devices that alloying of tungsten manufacturer also contribute to. The company gives these super alloys that have good mechanical stability even under the most rigorous conditions like vibration and impact, thus becoming a necessity in the demanding engineering environments.

While the industries are transforming themselves by using lighter but tougher materials, alloying of tungsten manufacturer will most likely resort to AI-based design and smart manufacturing systems. Real-time monitoring of the consistency of the alloy and its mechanical behavior will be made possible by these innovations. Sustainability will be the main emphasis of future development, thereby recycling technologies cutting down on raw material waste but still keeping the structural excellence of tungsten heavy alloys.

alloying of tungsten manufacturer underscore the need for preventive maintenance of tungsten heavy alloy components. The material should not be in contact with strong acids or bases which can lead to the alteration of its surface properties. Also, the gradual cooling of the components after machining or welding is necessary to avoid stress cracking. Through the provision of clean and temperature-controlled storage, the user can increase the service life of each alloy product.

alloying of tungsten manufacturer have built a solid reputation in the metalworking industry due to their proficiency in tungsten heavy alloy production. They merge advanced metallurgy with precise engineering to create materials that are guaranteed to perform consistently even in the most demanding conditions. alloying of tungsten manufacturer serve clients in the defense, medical, and aerospace industries, and they reinforce the concepts of reliability, consistency, and strength in every alloy they produce.

Q: How does Tungsten heavy alloy behave under mechanical stress? A: It maintains high strength and toughness, resisting deformation even under repetitive or heavy loading. Q: What makes Tungsten heavy alloy suitable for high-precision components? A: Its stability and fine-grained structure enable accurate machining and consistent mechanical performance. Q: Why is Tungsten heavy alloy used in sporting equipment? A: It provides balanced weight distribution and durability for tools like darts, golf clubs, and fishing weights. Q: What temperatures can Tungsten heavy alloy endure? A: It can withstand temperatures exceeding 1000°C without losing strength or structural integrity. Q: Is Tungsten heavy alloy safe for human contact? A: Yes, it is non-toxic and biocompatible, making it safe for use in medical and consumer applications.

I appreciate that Tungsten heavy alloy is non-toxic yet just as heavy and stable as lead — a smart upgrade.

The Tungsten heavy alloy has impressive density and strength — it’s perfect for high-performance machinery.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

We are a machining parts supplier seeking tungsten heavy alloy rods for precision components. Kindly...

I’m interested in your tungsten jig models used for saltwater fishing. Please share your catalog a...

Copyright © Zhuzhou Jiuding Metal Technology Co., Ltd. All Rights Reserved