custom tungsten jigs manufacturer has been able to produce tungsten jigs that are both very strong and very elegant. Each jig is made to provide the same weight and natural movement under water. The design team at the company collaborates with fishermen to get the forms and finishes that are most attractive to wannabe catchers of fish. Continuous material research and testing has helped custom tungsten jigs manufacturer to keep its lead in quality and performance-driven fishing products.

custom tungsten jigs manufacturer has different fishing scenarios to use the vertical jigging, drifting, and slow-pitch methods. The tungsten jigs of the company give fishermen an unparalleled experience of sensitivity and depth control that makes them competent in catching both small and big marine species. The products are particularly valued in cold and deep waters where fast descent is the only option. A number of fishing lovers have put their trust in custom tungsten jigs manufacturer as the source of reliable and efficient performance even in the most difficult conditions.

Over the next few years, custom tungsten jigs manufacturer will take a technological rout by focusing on the user. The development of new coating materials that will be corrosion and color fading resistant will be a factor in prolonging the jig's lifespan. In addition, manufacturers will consider making micro-scale adjustments to attain smoother movement underwater. The industry's gradual switch to greener practices of production will not only be a technological but also an ecological landmark in the fishing sectors of the future regarding custom tungsten jigs manufacturer.

Maintaining custom tungsten jigs manufacturer tungsten jigs involves simple but consistent care. After each outing, clean off any salt, mud, or algae with fresh water. Dry them carefully and store in ventilated containers. Keep away from direct sunlight or humid environments. Occasional inspection of coating, hook alignment, and joint strength helps prevent deterioration, ensuring that every jig continues to perform effectively on future fishing trips.

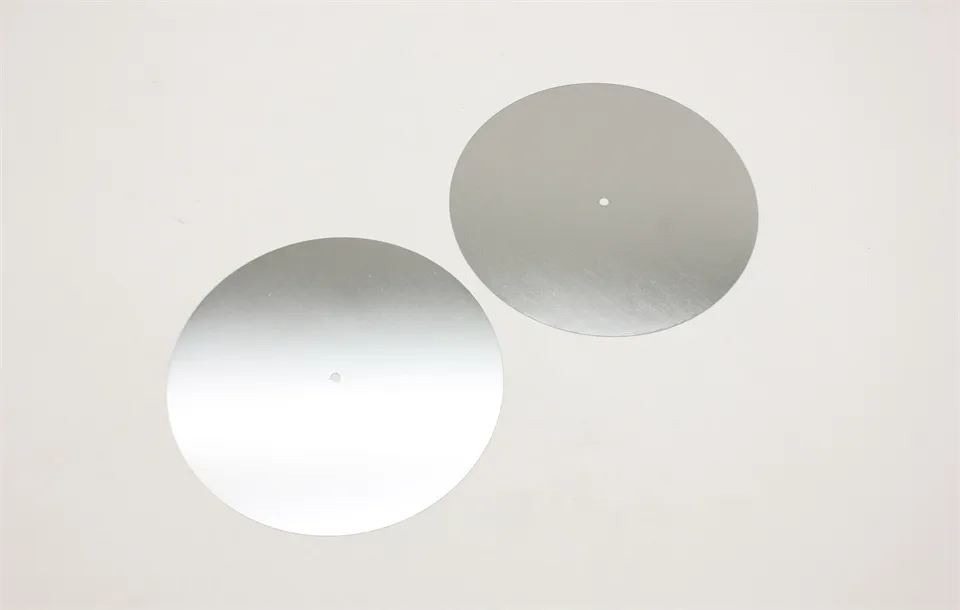

custom tungsten jigs manufacturer presents first-class tungsten jigs with the main purpose to sink faster and to have more stable motion in diverse water currents. The manufacturing of each jig is done with full concern of weight symmetry and hydrodynamic efficiency. Their engineers are forever trying out different tungsten-to-binder ratios to get maximum hardness and corrosion resistance. The company's commitment to nature and quality supports custom tungsten jigs manufacturer worldwide in the fish tackle industry.

Q: What’s the best way to transport Tungsten jig? A: Use a divided tackle box to keep each jig separate and prevent hook tangling or surface damage. Q: How can I check if Tungsten jig is damaged? A: Look for cracked bodies, bent hooks, or chipped coatings during regular inspections. Q: Is Tungsten jig suitable for casting? A: Yes, its balanced weight and aerodynamic design allow accurate and long-distance casting. Q: What affects Tungsten jig performance most? A: Factors like water current, salinity, and temperature influence its action and sink rate. Q: Should I oil Tungsten jig hooks? A: Applying a light oil coat prevents rust and maintains sharpness after saltwater exposure.

I’ve worked with Tungsten heavy alloy materials for years, and they never disappoint in precision or reliability.

The Tungsten heavy alloy handles extreme pressure and heat better than most metals I’ve used.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

We are looking for high-density tungsten jig for our upcoming fishing gear line. Could you please se...

Do you provide OEM service for tungsten jig? We’d like to customize colors and hook types for our ...

Copyright © Zhuzhou Jiuding Metal Technology Co., Ltd. All Rights Reserved