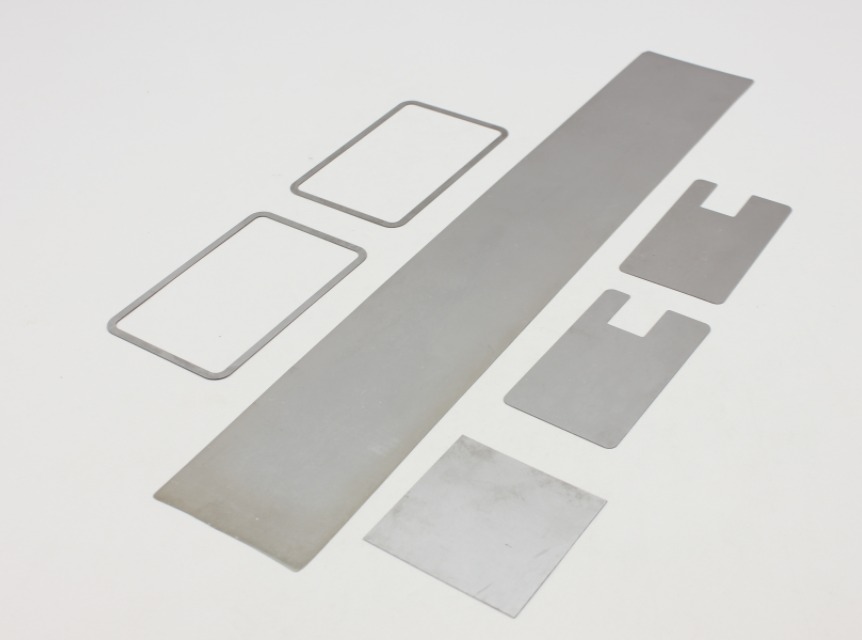

One of the greatest advantages of machining copper tungsten is its adaptability to specific application requirements. Its machinability allows manufacturers to create intricate components with precise dimensions. Whether it’s for medical devices, industrial machinery, or aerospace equipment, machining copper tungsten can be tailored to meet unique performance needs. Advanced manufacturing technologies further enhance its versatility, enabling complex designs and innovative solutions. For companies seeking customized materials that deliver consistent results, machining copper tungsten is a clear winner.

The machining copper tungsten is a key material for the defense market, used in kinetic energy penetrators, armor plate, and radiation shielding. Its high density provides deep penetration capability and resistance to impact. Unlike traditional materials, machining copper tungsten retains mechanical integrity under extreme heat and stress. It offers high reliability in ballistic components, projectiles, and aircraft counterweights, improving both safety and performance in extreme defense applications worldwide.

The machining copper tungsten can be expected to trend towards higher fatigue resistance, with potential application in dynamic uses like energy absorption systems and power generation. Researchers are seeking to achieve additional grain refinement and mechanical elasticity. This will enhance service life and reduce structural fatigue in extreme industrial environments.

For marine or drilling application, machining copper tungsten components should be dried and cleaned after exposure to seawater or mud. Surface protection through plating or coating is recommended. Periodic inspection prevents surreptitious corrosion, enabling the part to maintain structural integrity and functional safety.

The medical industry leverages the unique properties of machining copper tungsten for various critical applications. machining copper tungsten’s high density and radiation shielding capabilities make it ideal for medical imaging devices, such as X-ray and CT scanners. It is also used in radiotherapy equipment to protect patients and medical personnel from harmful radiation. Additionally, machining copper tungsten is employed in surgical instruments, offering strength and precision for delicate procedures. The material’s biocompatibility further ensures safety when used in medical environments. machining copper tungsten is undoubtedly a cornerstone material for advancing healthcare technology.

Q: What is the expected lifespan of tungsten alloy products? A: Tungsten alloy products have a long lifespan due to their wear resistance, corrosion resistance, and structural integrity. In most applications, they can last for years with minimal maintenance. Q: How does tungsten alloy compare to steel in terms of performance? A: Tungsten alloy is much denser than steel, providing higher strength and durability in a smaller size. It is ideal for applications requiring compact yet robust materials, outperforming steel in high-stress environments. Q: What is the shipping process for international buyers? A: We work with reliable logistics partners to ensure timely and safe delivery. Buyers can choose air, sea, or express shipping options, and we provide tracking information for all orders. Q: Are tungsten alloy products safe for regular handling? A: Yes, tungsten alloy is non-toxic and safe for handling. It does not pose the health risks associated with lead or other hazardous materials, making it a secure choice for various applications. Q: What industries benefit most from tungsten alloy? A: Industries such as aerospace, defense, automotive, medical, energy, and marine benefit from tungsten alloy’s unique properties. Its versatility and high performance make it a preferred material in many sectors.

The tungsten jig performs great in both saltwater and freshwater; it doesn’t rust or wear out easily.

I’ve worked with Tungsten heavy alloy materials for years, and they never disappoint in precision or reliability.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

Do you provide OEM service for tungsten jig? We’d like to customize colors and hook types for our ...

We need tungsten heavy alloy plates for counterweight applications. Please share available thickness...

Copyright © Zhuzhou Jiuding Metal Technology Co., Ltd. All Rights Reserved