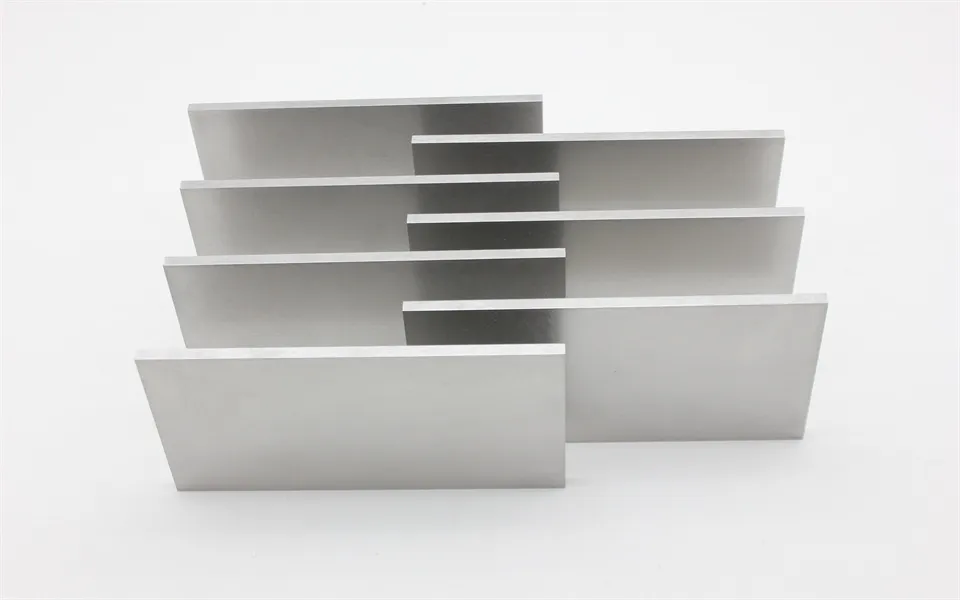

tungsten alloy bar manufacturer are highlighted by their precision manufacturing and technical know-how. The production of their tungsten heavy alloys is through mixing and sintering processes that are advanced and result in nano-size microstructures. It means stabling of both physical and mechanical properties. Continuous quality control at tungsten alloy bar manufacturer ensures that the product has strength, density and corrosion resistance, thus giving the reliable performance of their alloys in tough industrial environments.

tungsten alloy bar manufacturer are the producers of tungsten heavy alloys that are critical in engineering and medical applications. They are the ones used for shielding, balancing, and tooling where compact mass and resistance to deformation are the most important features. The knowledge of tungsten alloy bar manufacturer in alloy blending guarantees that each product provides the qualities of stability, longevity, and precision performance even under the stress of operational conditions.

{Keywords} future will be dictated by following the trends such as sustainability and circular economy. On the one hand, recycling programs and raw material recovery processes will lower production costs and the overall impact of the factory on the environment. On the other hand, the use of recycling techniques in the metallurgical processes will only be using the best performance alloys, this enabling tungsten alloy bar manufacturer to be green metal manufacturers in the high-density metals sector.

tungsten alloy bar manufacturer suggest non-reactive oils or lubricants as a means of protection throughout storage and transportation. Moreover, alcohol cleaning is necessary before installation in order to get rid of residues. Discolouration and crevice fatigue tests for high-temperature or radiation exposed parts are to be done periodically to assure quality and reliability over time.

tungsten alloy bar manufacturer is a company that primarily deals with the research and manufacture of tungsten-based materials, which are heavy yet still possess great mechanical properties. The engineers are very aware of the demanding application areas and thus the production of counterweights, kinetic energy penetrators, and shielding components are just a few to name. All this is achieved through continuous research and upgraded processing technology, which by the way keeps the standards of global engineering markets for their products as they have uniform density, superior hardness, and high resistance to wear.

Q: How does Tungsten heavy alloy behave under mechanical stress? A: It maintains high strength and toughness, resisting deformation even under repetitive or heavy loading. Q: What makes Tungsten heavy alloy suitable for high-precision components? A: Its stability and fine-grained structure enable accurate machining and consistent mechanical performance. Q: Why is Tungsten heavy alloy used in sporting equipment? A: It provides balanced weight distribution and durability for tools like darts, golf clubs, and fishing weights. Q: What temperatures can Tungsten heavy alloy endure? A: It can withstand temperatures exceeding 1000°C without losing strength or structural integrity. Q: Is Tungsten heavy alloy safe for human contact? A: Yes, it is non-toxic and biocompatible, making it safe for use in medical and consumer applications.

The craftsmanship of the tungsten jig is excellent — it reacts quickly to every move of the rod.

The tungsten jig performs great in both saltwater and freshwater; it doesn’t rust or wear out easily.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

Do you provide OEM service for tungsten jig? We’d like to customize colors and hook types for our ...

Could you provide your latest price list and production capacity for tungsten heavy alloy bars? We p...

Copyright © Zhuzhou Jiuding Metal Technology Co., Ltd. All Rights Reserved