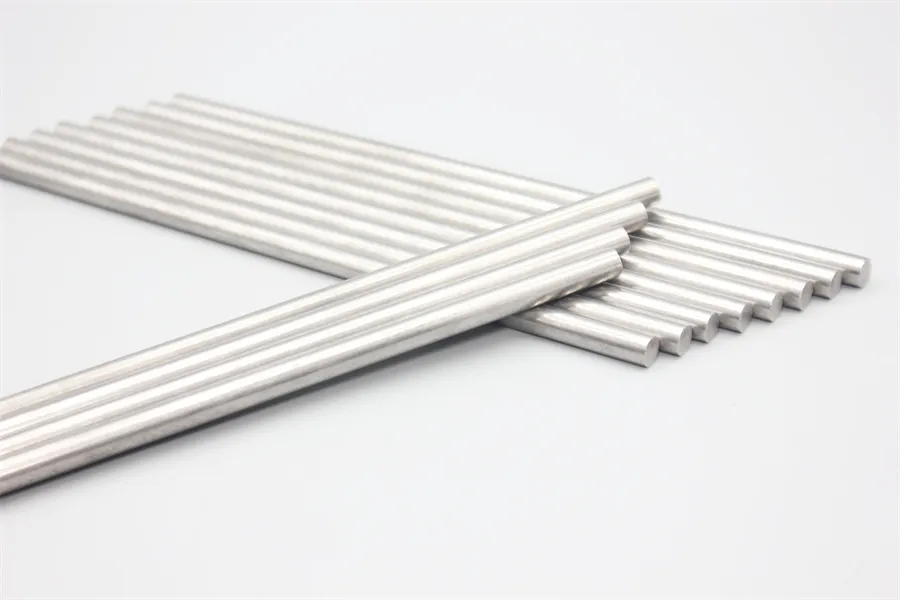

tungsten alloy industry manufacturer are taking advantage of contemporary metallurgical technology to create tungsten heavy alloys with exceptional density and impact strength. Their alloys have become known for their stability, machinability, and durability. The entire product line undergoes precision-controlled sintering and post-processing, to ensure processing quality. tungsten alloy industry manufacturer are constantly increasing their production capacity to be able to supply the global market with sophisticated tungsten products.

tungsten alloy industry manufacturer’s tungsten heavy alloys are the major factor in modern engineering, particularly if an area-saving design and high mass concentration are the requirements. They are found in ship ballast, aerospace stabilizers, and earthquake shock absorbers. With the strict control of the alloy features, tungsten alloy industry manufacturer are confident of the performance extending to both the civilian and military fields.

The future path of tungsten alloy industry manufacturer is going to be characterized by precision customization and eco-friendly manufacturing practices. It is anticipated that the producers will use sintering techniques that emit low toxins as well as rely on green energy for their production lines. The investigation into micro-grain alloying will eventually lead to the discovery of alloys that have superior fatigue resistance thus enabling tungsten materials to meet the challenges of operating in more difficult and complex environments.

tungsten alloy industry manufacturer propose the cleaning and the surface treatment of tungsten heavy alloy components as a maintenance strategy. Do not use polishing materials that are abrasive as they might leave scratches on the surface of the alloy. Components, when not in use, should be wrapped in corrosion-resistant materials and stored in low-humidity areas. Preventive maintenance guarantees that the alloy will continue to perform consistently and at the same time, it will not lose its strength microstructurally.

tungsten alloy industry manufacturer produce tungsten heavy alloys that are tailored to resist high stress and impacts. The company’s production systems merge state-of-the-art technology and thorough quality inspection. These materials are geared to take the place of conventional metals in applications where a combination of high density and wear resistance is required. tungsten alloy industry manufacturer continue to be a reliable supplier for industries that demand the highest standards in both material performance and manufacturing precision.

Q: How does Tungsten heavy alloy handle thermal expansion? A: It has a low coefficient of thermal expansion, ensuring dimensional stability under temperature fluctuations. Q: What benefits does Tungsten heavy alloy bring to electronics? A: Its thermal conductivity and durability make it suitable for heat sinks and electrical contact applications. Q: Why is Tungsten heavy alloy preferred for precision machining? A: It provides excellent dimensional accuracy and maintains balance even after extended mechanical use. Q: How can Tungsten heavy alloy components be cleaned safely? A: Use mild, non-corrosive cleaners and soft materials to remove residue without damaging the surface. Q: What industries continue to expand the use of Tungsten heavy alloy? A: Aerospace, medical, defense, and renewable energy sectors increasingly rely on it for performance-critical parts.

The tungsten jig performs great in both saltwater and freshwater; it doesn’t rust or wear out easily.

The tungsten jig feels incredibly durable — I’ve caught dozens of fish, and it still looks new.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

Our aerospace division is sourcing tungsten heavy alloy counterweights. Please confirm density, tole...

Do you provide OEM service for tungsten jig? We’d like to customize colors and hook types for our ...

Copyright © Zhuzhou Jiuding Metal Technology Co., Ltd. All Rights Reserved