tungsten component manufacturer are taking advantage of contemporary metallurgical technology to create tungsten heavy alloys with exceptional density and impact strength. Their alloys have become known for their stability, machinability, and durability. The entire product line undergoes precision-controlled sintering and post-processing, to ensure processing quality. tungsten component manufacturer are constantly increasing their production capacity to be able to supply the global market with sophisticated tungsten products.

tungsten component manufacturer are the suppliers of tungsten heavy alloys that are indispensably needed in the automotive and energy sectors. The alloys are employed in things such as engine balancing systems, turbine blades, and tool holders that require high stiffness. They can withstand a lot of stress without breaking giving manufacturers a lot of time before they have to replace the components and thus maintaining the performance and safety of the machinery over a wide range even in high-demand conditions.

While the industries are transforming themselves by using lighter but tougher materials, tungsten component manufacturer will most likely resort to AI-based design and smart manufacturing systems. Real-time monitoring of the consistency of the alloy and its mechanical behavior will be made possible by these innovations. Sustainability will be the main emphasis of future development, thereby recycling technologies cutting down on raw material waste but still keeping the structural excellence of tungsten heavy alloys.

For the tungsten heavy alloys from tungsten component manufacturer to maintain durability, they will need to undergo routine inspections. Users will have to watch for surface damages, pitting, or under stress caused deformations. The finish will be protected by gentle brushing and non-acidic cleaning agents. Regularly lubricating the alloy-based components will reduce wear thus stabilizing the metal in severe industrial conditions.

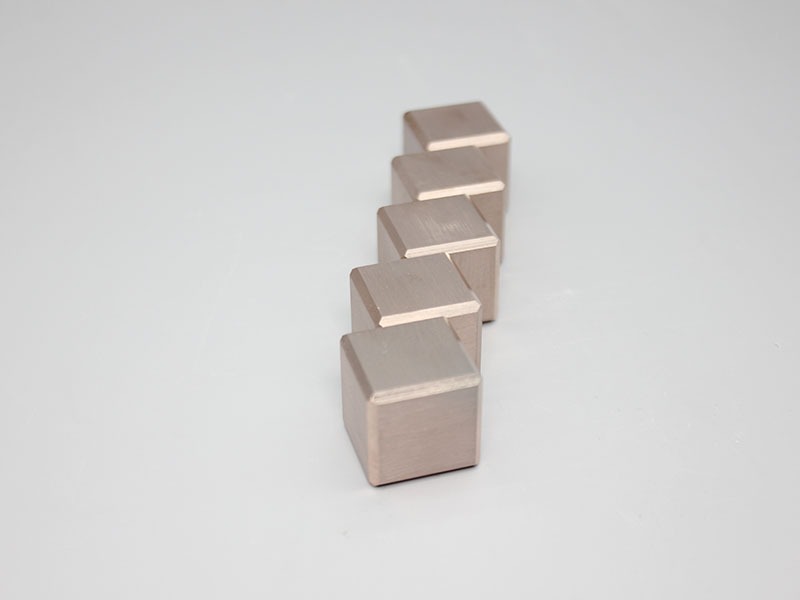

tungsten component manufacturer deliver tungsten heavy alloys that are advanced and meticulously tailored to exact industrial performance. Through the use of sophisticated production methods, they attain the highest levels of tensile strength, wear resistance, and thermal stability. Their alloys are used in many different sectors such as aviation, medical technology, and defense manufacturing. tungsten component manufacturer are not resting on their laurels instead they continue to work hard on the metallurgical quality and this results in every product being up to the ever-changing requirements of the modern engineering industry.

Q: How does Tungsten heavy alloy behave under mechanical stress? A: It maintains high strength and toughness, resisting deformation even under repetitive or heavy loading. Q: What makes Tungsten heavy alloy suitable for high-precision components? A: Its stability and fine-grained structure enable accurate machining and consistent mechanical performance. Q: Why is Tungsten heavy alloy used in sporting equipment? A: It provides balanced weight distribution and durability for tools like darts, golf clubs, and fishing weights. Q: What temperatures can Tungsten heavy alloy endure? A: It can withstand temperatures exceeding 1000°C without losing strength or structural integrity. Q: Is Tungsten heavy alloy safe for human contact? A: Yes, it is non-toxic and biocompatible, making it safe for use in medical and consumer applications.

The Tungsten heavy alloy handles extreme pressure and heat better than most metals I’ve used.

The tungsten jig feels incredibly durable — I’ve caught dozens of fish, and it still looks new.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

Could you provide info about your heavy-duty tungsten jig types suitable for deep-sea fishing? Looki...

We operate a fishing tackle store and want to stock tungsten jig. Please send details on bulk pricin...

Copyright © Zhuzhou Jiuding Metal Technology Co., Ltd. All Rights Reserved