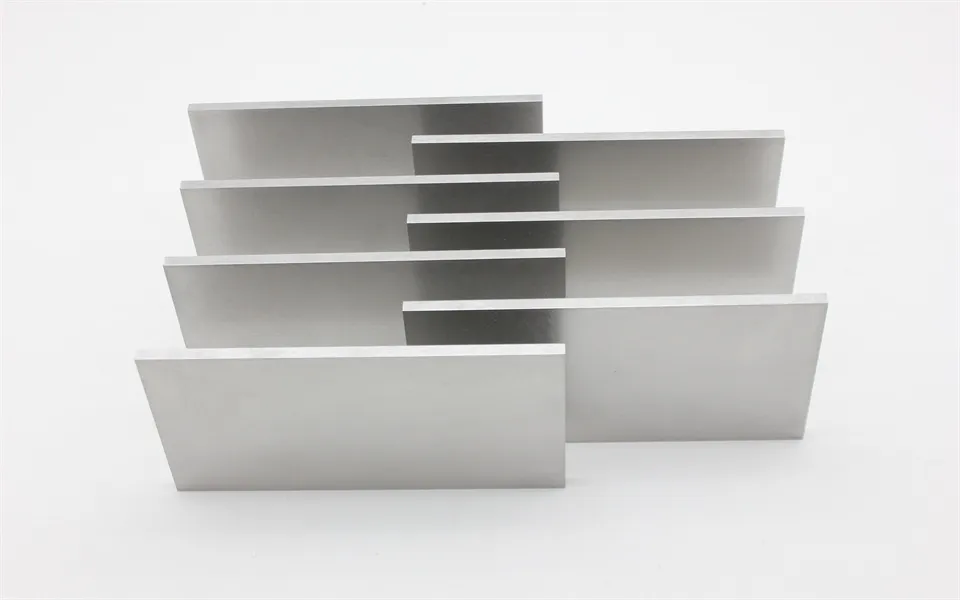

One of the greatest advantages of tungsten copper rod is its adaptability to specific application requirements. Its machinability allows manufacturers to create intricate components with precise dimensions. Whether it’s for medical devices, industrial machinery, or aerospace equipment, tungsten copper rod can be tailored to meet unique performance needs. Advanced manufacturing technologies further enhance its versatility, enabling complex designs and innovative solutions. For companies seeking customized materials that deliver consistent results, tungsten copper rod is a clear winner.

In medicine, tungsten copper rod is responsible for radiation shielding in diagnostic and therapy devices. It is its density that allows it to be a good shield for X-ray devices, CT scanners, and radiotherapy rooms. The tungsten copper rod offers thinner shields with the same degree of absorption, making protection and space-saving optimum. It is also used for syringe shields and collimators, where it lends strength and protection under high-radiation environments. Hospitals and laboratories are increasingly relying on tungsten copper rod for environmentally friendly shielding solutions.

Deep-sea and space industries will increasingly rely on tungsten copper rod. Its resistance to corrosion, pressure, and radiation ensures performance where other metals cannot. Future research may produce lighter, stronger forms of tungsten copper rod, which will further encompass its role in precision-engineered exploration equipment and extreme-environment missions.

For marine or drilling application, tungsten copper rod components should be dried and cleaned after exposure to seawater or mud. Surface protection through plating or coating is recommended. Periodic inspection prevents surreptitious corrosion, enabling the part to maintain structural integrity and functional safety.

One of the standout features of tungsten copper rod is its machinability, which allows for highly customized applications. Despite its density and strength, tungsten copper rod can be precisely shaped into complex forms, meeting the specific needs of various industries. Advanced machining techniques enable the production of tungsten copper rod components with tight tolerances, ensuring compatibility with high-performance systems. From medical equipment to industrial machinery, the ability to customize tungsten copper rod enhances its versatility. Manufacturers seeking tailored solutions can rely on tungsten copper rod to deliver precision and durability.

Q: What is the minimum quantity I can order for tungsten alloy products? A: We accommodate a variety of order sizes, from small batches for prototypes to large-scale production orders. Our minimum order quantity (MOQ) depends on the product type and level of customization, ensuring flexibility for both small and large buyers. Q: How do you handle international shipping for tungsten alloy products? A: We offer secure and efficient international shipping through trusted logistics providers. Whether by air, sea, or courier, we ensure proper documentation, safe packaging, and tracking for a smooth delivery process to your location. Q: Are tungsten alloy products subject to export restrictions? A: Tungsten alloy products are generally not subject to export restrictions, but we comply with international trade regulations and provide all necessary documentation to facilitate smooth customs clearance. Buyers should verify any specific import restrictions in their country. Q: What payment methods do you accept for international buyers? A: We accept various payment methods, including wire transfers (T/T), letters of credit (L/C), and online payment options like PayPal. We are happy to work with buyers to establish a payment plan that meets their requirements. Q: Can you provide samples of tungsten alloy products before placing a large order? A: Yes, we offer samples to help buyers evaluate the quality and specifications of our tungsten alloy products. Sample costs and shipping fees can be discussed based on the specific request, and we aim to make this process easy for our clients.

The Tungsten heavy alloy handles extreme pressure and heat better than most metals I’ve used.

The tungsten jig performs great in both saltwater and freshwater; it doesn’t rust or wear out easily.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

We are interested in tungsten heavy alloy cylinders for kinetic energy applications. Could you send ...

We are looking for high-density tungsten jig for our upcoming fishing gear line. Could you please se...

Copyright © Zhuzhou Jiuding Metal Technology Co., Ltd. All Rights Reserved