tungsten heavy alloy price per kg 2025 showcases a remarkable mixture of power, flexibility, and thermal fatigue resistance. It is able to endure high pressure and very high temperatures getting neither through mechanical consistency. The aforementioned properties are a reason for its usage in the aerospace industry, particularly in flight control systems, radiations, and oil drilling. Besides that, its long-term dimensional accuracy cuts down on maintenance frequency while at the same time guaranteeing the quality of output.

Because of density and strength, tungsten heavy alloy price per kg 2025 are well-suited for precision machinery applications requiring precise balancing and vibration control. Examples include flywheels and dynamic dampers, as well as automotive applications for crankshaft weights or other components. {Keywords} absorb vibration, extends the life of machines, and improves performance when used in high speed operational conditions.

{Keywords} provides white space for development in future advanced space exploration applications. As expected, lighter, radiation resistant composites derived from a process involving tungsten heavy alloy price per kg 2025 will be needed for deep space missions. The future of tungsten heavy alloy price per kg 2025 in further evolving powder metallurgy and 3D forming designs and processes will encourage further innovation for advanced aerospace applications.

Proper operating procedures are particularly important for general durability of tungsten heavy alloy price per kg 2025. Clean regularly, preferably with soft cloths, and store in a location away from magnets or corrosive materials. Look for cracks, wear, or discolorations in surfaces periodically to ensure continued reliability and to maintain safe operating conditions.

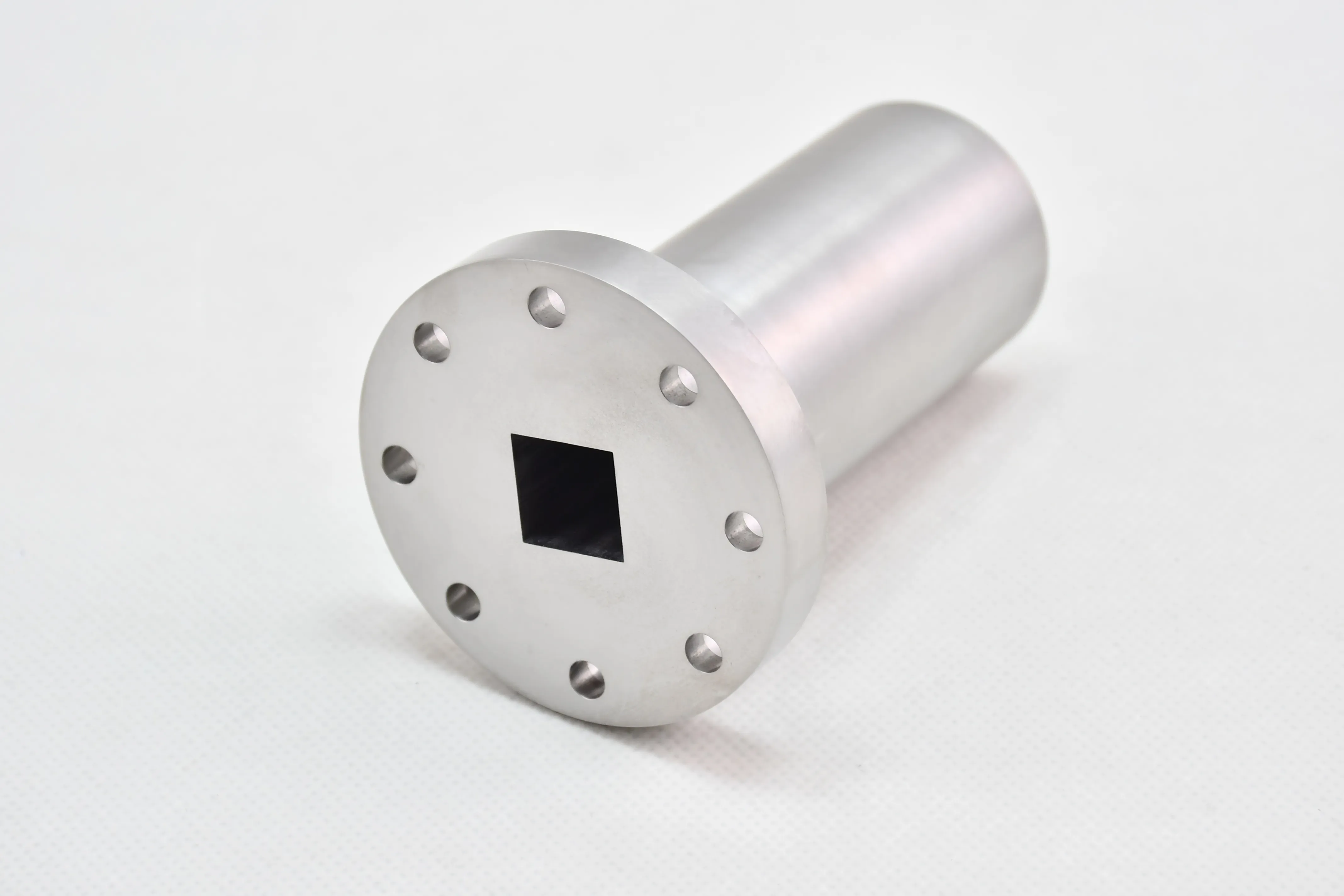

tungsten heavy alloy price per kg 2025 is a high-density material that is used in the aerospace, defense, and industrial sectors. Its strength, hardness, and wear resistance make it usable in environments where durability is needed and where weight distribution is compact. tungsten heavy alloy price per kg 2025 offers excellent radiation shielding and thermal stability and continues to perform in high-temperature and high-stress situations.

Q: How does Tungsten heavy alloy differ from pure tungsten? A: While pure tungsten is brittle, Tungsten heavy alloy has improved ductility and strength due to the addition of metal binders like nickel or iron. Q: Why is Tungsten heavy alloy used in medical imaging devices? A: It provides excellent radiation attenuation while maintaining compactness, ensuring precision and safety in X-ray and CT applications. Q: How durable is Tungsten heavy alloy in long-term use? A: It offers excellent wear and corrosion resistance, ensuring long-lasting performance in industrial and defense systems. Q: Can Tungsten heavy alloy be welded or joined easily? A: Yes, it can be joined using brazing or mechanical methods, though proper temperature control is required to maintain structural stability. Q: What role does Tungsten heavy alloy play in the defense industry? A: It is used for armor-piercing projectiles, kinetic energy penetrators, and vibration damping in high-performance military equipment.

The tungsten jig performs great in both saltwater and freshwater; it doesn’t rust or wear out easily.

I appreciate that Tungsten heavy alloy is non-toxic yet just as heavy and stable as lead — a smart upgrade.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

I’m interested in your tungsten jig models used for saltwater fishing. Please share your catalog a...

We are a machining parts supplier seeking tungsten heavy alloy rods for precision components. Kindly...

Copyright © Zhuzhou Jiuding Metal Technology Co., Ltd. All Rights Reserved