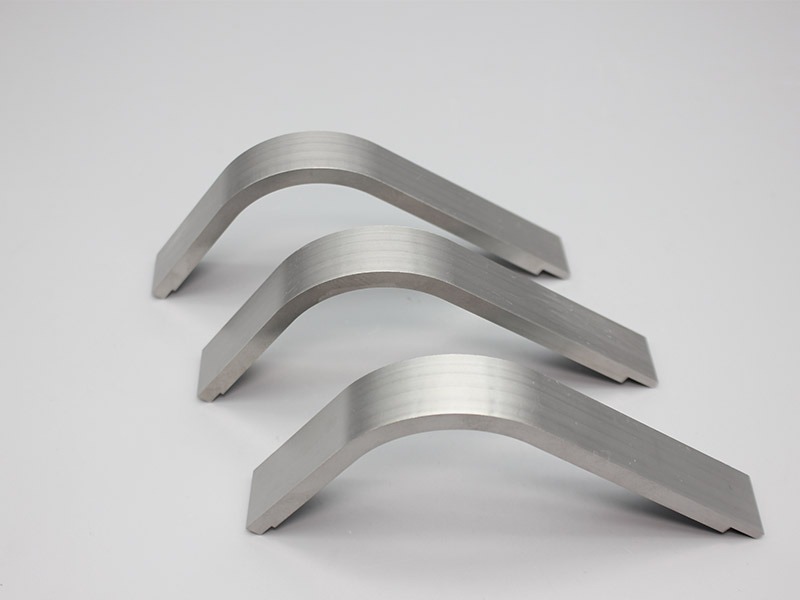

The quality of tungsten heavy alloys applications is not just versatile; it is also strong and dense at the same time, which enables it to be efficiently used in small spaces. Its production involves merging tungsten with either nickel and iron or copper, resulting in a material that is rugged as well as easy to machine. This alloy possesses all the necessary features required in aerospace, defense, and power generation industries. Its precise weight distribution properties additionally open up the manufacture of counterweights, radiation shields, and high-impact tools that require constantly dependable quality.

The use of tungsten heavy alloys applications covers industries that require high strength-to-weight ratios and structural integrity. In aerospace engineering, it is found in counterweights for aircraft, balancing rotors, and control surfaces, where tolerance is important. The defense industry employs tungsten heavy alloys applications in armor-piercing projectiles and for kinetic energy components, due to its high mass density and ability to withstand impact. Additionally, it serves oil drilling and heavy machinery applications for precision machining and stability under extreme vibration.

Accelerating technological miniaturization will ensure tungsten heavy alloys applications have a primary role in creating small, high-precision components. Its thermal management capability will allow micro-electronic devices, and its dependability will grant advantages to industries like robotics, aerospace, and defense; all of which are concerned with extreme accuracy.

Good maintenance of tungsten heavy alloys applications ensures durable performance in extreme conditions. Periodically inspect mechanical joint and contact areas to detect early wear. In instances when oxidation has formed, buff the appearace with a mild abrasive pad. You can expect the oxidation to lose its unwanted appearance, but the performance of the tungsten heavy alloys applications will not be adversely affected.

tungsten heavy alloys applications is specifically designed for high performance applications, combining hardness with good machinability. Common applications include for counter weights, ballistic applications, and vibration damping structures. The consistent physical properties of the material provide a high level of precision and durability in a final product.

Q: What makes Tungsten heavy alloy essential in engineering applications? A: Tungsten heavy alloy is essential because of its exceptional density, hardness, and thermal stability, making it reliable for use in high-performance mechanical and structural components. Q: How is Tungsten heavy alloy produced? A: It is made through powder metallurgy, where tungsten powder is blended with nickel, iron, or copper and sintered at high temperatures to form a compact, durable alloy. Q: Why is Tungsten heavy alloy suitable for aerospace industries? A: Its superior weight distribution and resistance to thermal stress make it perfect for use in counterbalances, rotor systems, and aircraft control components. Q: Can Tungsten heavy alloy be machined easily? A: While it is very dense and hard, it can be precisely machined using specialized tools designed for high-strength materials. Q: In which fields is Tungsten heavy alloy commonly applied? A: It is widely used in defense, medical imaging, oil drilling, aerospace, and industrial balancing systems.

I’ve used the tungsten jig for months, and its weight balance makes it super easy to control even in deep spots.

The Tungsten heavy alloy handles extreme pressure and heat better than most metals I’ve used.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

I’m interested in your tungsten jig models used for saltwater fishing. Please share your catalog a...

Could you provide info about your heavy-duty tungsten jig types suitable for deep-sea fishing? Looki...

Copyright © Zhuzhou Jiuding Metal Technology Co., Ltd. All Rights Reserved