At every step of the jig manufacturing process, tungsten shaky head jig manufacturer employs tungsten as the primary material due to its durability and hydrodynamic efficiency. The resulting jigs are not only heavy but also capable of mimicking the movement of the bait. The cutting-edge coating technology applied by the factory prevents the jigs from losing their original properties through saltwater exposure. tungsten shaky head jig manufacturer is thus continuously enhancing its offerings through research and development-driven innovations.

tungsten shaky head jig manufacturer products are the undeniable choice of both professional and amateur fishermen. Their tungsten jigs are the favorite choice for deep-sea and ice fishing because of their minuscule weight and incredible sinking speed. These jigs give complete control even in the strongest of currents, thus making it possible to accurately fish for bass, snapper, and cod among others. tungsten shaky head jig manufacturer designs are even suitable for competitive tournaments where accuracy and to durability are the main factors for achieving consistent results.

New materials and care for the earth will be the main themes of tungsten shaky head jig manufacturer advancements in the next years. The producers plan on cutting tungsten scrap to the utmost minimum by means of their state-of-the-art recycling and recovering systems. Compression design software will not only make it easier to weight optimization and motion analysis but also improve the overall design of the product. tungsten shaky head jig manufacturer will go on creating new, colorful and trend-setting, surface finishes that resist abrasion and still look good, hence such jigs will be popular in both fresh and saltwater fishing for a long time.

Using tungsten shaky head jig manufacturer products with care guarantees their long-lasting existence and reliability in performance. Every time after indicated use, the tungsten jigs have to be washed with clean water to get rid of salt, sand, and dirt. It is advisable to completely dry them up before putting them away to keep the metal parts from rusting. Don't store them in wet or tight places. Upsurge checks of any wear and tear on the surface, hooks being loose, or coating being damaged, and use of either protective oil or silicone spray for the purpose of maintaining smooth performance should be a routine.

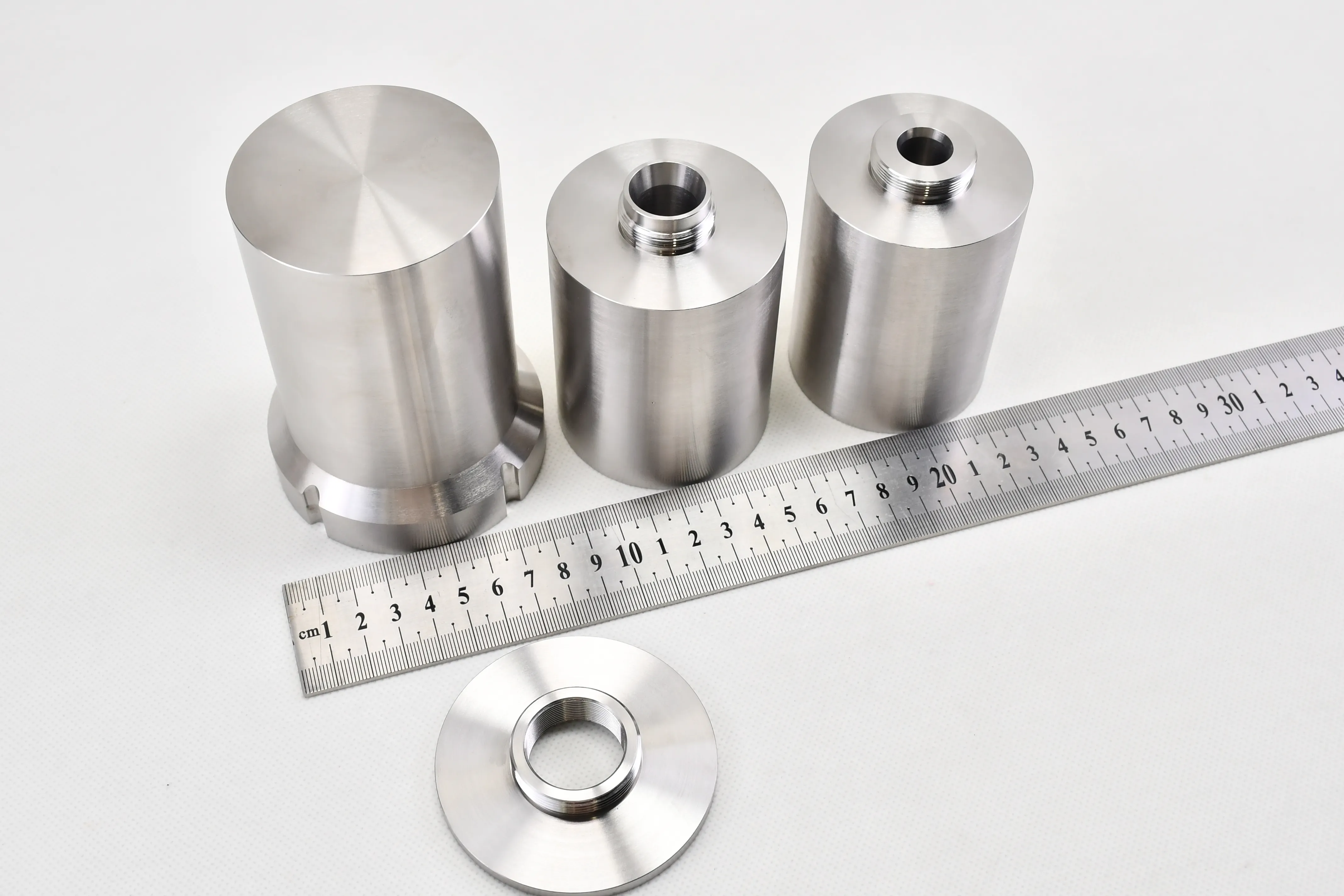

tungsten shaky head jig manufacturer is all about making hard-wearing and efficient tungsten jigs that not only improve the accuracy of the fishermen but also the depth performance. The manufacturers use diverse techniques that include high-pressure sintering, polishing, and more to achieve smooth finishes and uniformity in density. The jigs come with features that reduce drag, enable better movement of the fake, and accept different water conditions. tungsten shaky head jig manufacturer not only does sizing and coloring but also shapes the jigs according to the fish's likes, thus providing excellent saltwater and freshwater catches.

Q: How does Tungsten jig perform in deep-sea fishing? A: Its density ensures quick descent and excellent control, making it perfect for deep-water species. Q: Are there standard sizes for Tungsten jig? A: Yes, they range from micro jigs for panfish to heavy models for deep-sea applications. Q: What’s the ideal retrieval speed for Tungsten jig? A: Moderate to fast retrieves often trigger strikes, but speed should match the target species. Q: Can I repaint Tungsten jig myself? A: Yes, marine-safe paints and sealants work well for restoring color and protection. Q: How does care impact Tungsten jig’s lifespan? A: Regular cleaning, drying, and inspection greatly extend its performance and durability.

I’ve used the tungsten jig for months, and its weight balance makes it super easy to control even in deep spots.

The Tungsten heavy alloy handles extreme pressure and heat better than most metals I’ve used.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

We are interested in tungsten heavy alloy cylinders for kinetic energy applications. Could you send ...

We need tungsten heavy alloy plates for counterweight applications. Please share available thickness...

Copyright © Zhuzhou Jiuding Metal Technology Co., Ltd. All Rights Reserved