tungsten sharpening jig manufacturer gives tungsten jigs with perfect balance, fine detail, and high density. The company uses special sintering technology to make fishing weights that are both consistent and durable. Every product is checked for dimensional accuracy and surface smoothness, thus providing superior water performance. With years of expertise in metalworking, tungsten sharpening jig manufacturer has not only kept up with modern fishing trends and demands but has also continued to evolve.

The usages of tungsten sharpening jig manufacturer are diverse as they involve saltwater, freshwater, and coastal environments. From among the many applications, the main one is to the using of tungsten jigs by the fishermen who use them to attract fish by keeping jigs steady with varying conditions. Sensitivity is heightened due to the jigs and this leads to higher efficiency in reaching the target fish. Besides, tungsten sharpening jig manufacturer also provides tailor-made designs according to the fishing techniques being used, such as vertical jigging, bottom bouncing, and slow pitch, which is a mix of professional and commercial sectors.

The tungsten sharpening jig manufacturer development trend is towards higher efficiency and less impact on the environment. Energy-efficient furnaces and digital monitoring systems will be installed in future factories to not only save energy but also to enhance production accuracy. More jig varieties to suit different fishing techniques will be made available. tungsten sharpening jig manufacturer also intends to work with material scientists to develop new tungsten composites for professional use that are lighter and just as strong as the current ones.

Using tungsten sharpening jig manufacturer products with care guarantees their long-lasting existence and reliability in performance. Every time after indicated use, the tungsten jigs have to be washed with clean water to get rid of salt, sand, and dirt. It is advisable to completely dry them up before putting them away to keep the metal parts from rusting. Don't store them in wet or tight places. Upsurge checks of any wear and tear on the surface, hooks being loose, or coating being damaged, and use of either protective oil or silicone spray for the purpose of maintaining smooth performance should be a routine.

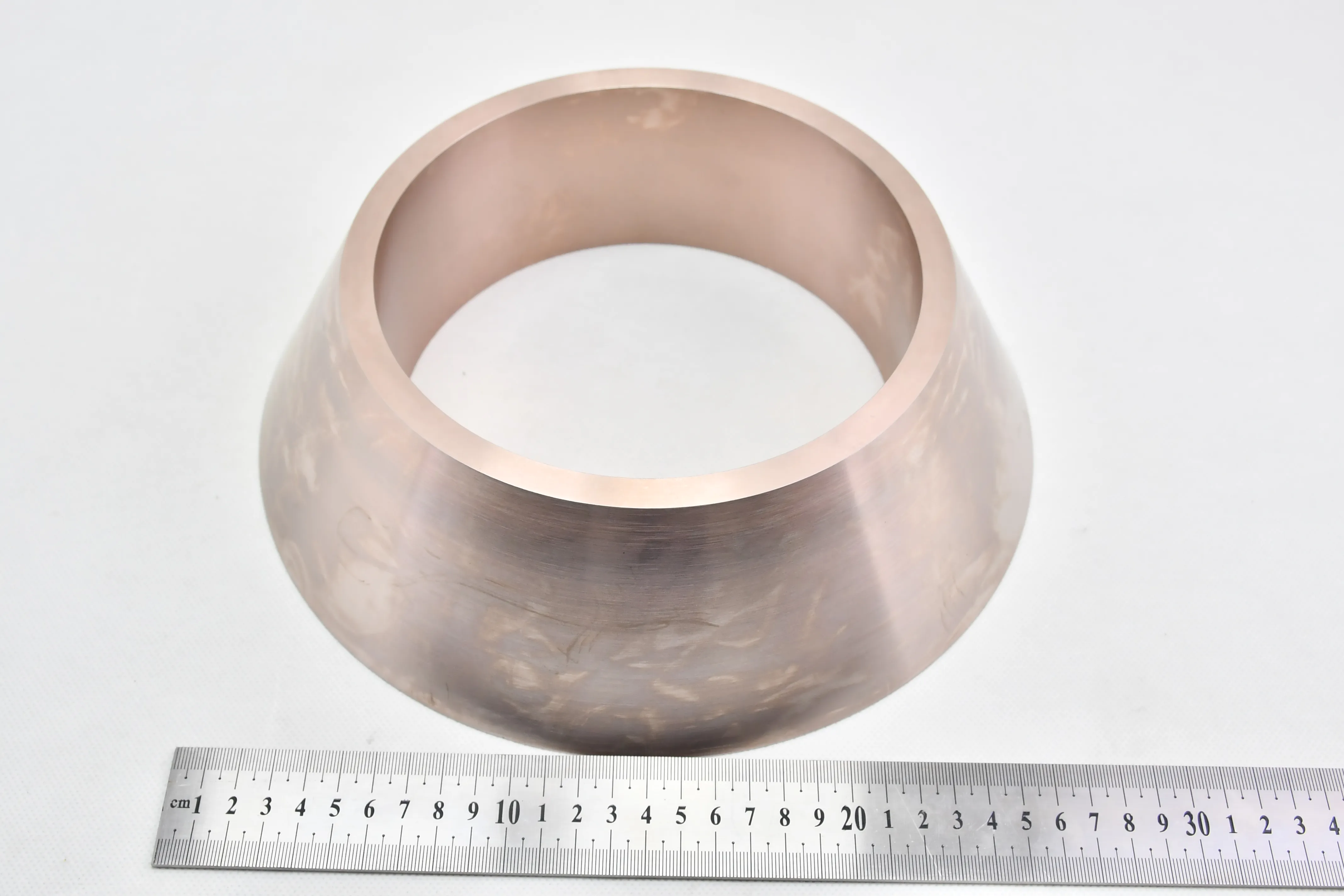

tungsten sharpening jig manufacturer is very dedicated to making tungsten jigs that are precise as well as durable. Their factory has automated systems that provide dimensional controls that are very tight, and this in turn reduces the inconsistencies in the product batches. These jigs are made for saltwater's long-term exposure without losing their effectiveness. tungsten sharpening jig manufacturer used advanced metal bonding and coating processes and thus still jigs that can win both the sport and commercial fishing areas.

Q: What are the main benefits of Tungsten jig? A: It offers faster sinking, better sensitivity, smaller size, and superior underwater control compared to lead jigs. Q: Is Tungsten jig safe for marine environments? A: Yes, it’s environmentally friendly and doesn’t release harmful substances into the water. Q: How often should I replace Tungsten jig? A: With proper care, it can last for years, though hooks should be replaced if damaged. Q: What storage conditions are best for Tungsten jig? A: Keep it dry and organized in a sealed box with anti-rust packets. Q: Can Tungsten jig be customized? A: Some brands offer custom options for weight, color, and hook size to match specific fishing needs.

The craftsmanship of the tungsten jig is excellent — it reacts quickly to every move of the rod.

The Tungsten heavy alloy handles extreme pressure and heat better than most metals I’ve used.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

Could you provide your latest price list and production capacity for tungsten heavy alloy bars? We p...

We operate a fishing tackle store and want to stock tungsten jig. Please send details on bulk pricin...

Copyright © Zhuzhou Jiuding Metal Technology Co., Ltd. All Rights Reserved