wnife stands out among industrial materials for its combination of density, strength, and corrosion resistance. It is highly valued in industries such as aerospace, automotive, and oil and gas for its ability to perform under extreme pressures and temperatures. wnife components are designed to endure heavy loads and harsh conditions, making them indispensable in high-stress environments. Its machinability also allows for precise customization, enabling manufacturers to meet specific application requirements. wnife is undoubtedly a top-tier choice for industrial solutions.

In sports and recreation equipment, wnife improves control and accuracy. Its density enables designs to be compact in darts, golf clubs, and racing weights. Engineers and sports persons appreciate how wnife optimizes balance and feedback without the addition of size or drag. Manufacturers rely on it to provide consistent performance, especially in competitive uses where weight distribution and stability are the secrets to winning.

Miniaturization trends in electronics will drive further innovation in wnife. High density and thermal stability serve it well in terms of suitability for heat sinks and EMI shields at small scale. With decreasing device sizes and higher speeds, the need for established materials like wnife will grow to achieve effective power control and long-term reliability in dense electronic assemblies.

Prolonged storage of wnife requires temperature and humidity control. Use sealed containers or desiccants to prevent moisture absorption. For mechanical components, re-lubrication at a few months' interval renders them resistant to corrosion and their smooth functioning. These measures guarantee increased service stability.

wnife is a critical material in the development of advanced ballistic solutions. Its high density and hardness make it an ideal choice for armor-piercing projectiles and counterweights in military applications. wnife’s ability to retain its properties under extreme conditions ensures superior performance in ballistic testing and real-world scenarios. Moreover, its non-toxic nature makes it a safer alternative to traditional materials like depleted uranium. For defense industries seeking reliable and eco-friendly materials, wnife offers unparalleled benefits.

Q: What are the environmental benefits of tungsten alloy? A: Tungsten alloy is recyclable and non-toxic, making it a sustainable choice. Its use as a replacement for lead and other hazardous materials helps industries reduce environmental impact while maintaining high performance. Q: How does tungsten alloy perform under extreme conditions? A: Tungsten alloy excels in high-temperature, high-pressure, and corrosive environments. Its superior mechanical properties ensure reliable performance in demanding applications like drilling, marine engineering, and defense systems. Q: What are the advantages of using tungsten alloy in counterweights? A: Tungsten alloy counterweights are compact yet highly dense, allowing precise weight distribution in limited spaces. They are widely used in elevators, cranes, robotics, and vehicles to ensure balance and stability. Q: What are the minimum order requirements for tungsten alloy products? A: Minimum order requirements vary depending on the product and customization level. As a manufacturer, we work closely with buyers to meet their needs, ensuring cost-effective solutions for small or large orders. Q: How is tungsten alloy used in medical applications? A: Tungsten alloy is used in radiation shielding for X-ray and CT scanners, as well as in medical instruments like collimators and syringes. Its high density provides effective protection while its biocompatibility ensures safety for medical use.

What I love about the tungsten jig is how fast it sinks and how naturally it moves in the water.

I appreciate that Tungsten heavy alloy is non-toxic yet just as heavy and stable as lead — a smart upgrade.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

Do you provide OEM service for tungsten jig? We’d like to customize colors and hook types for our ...

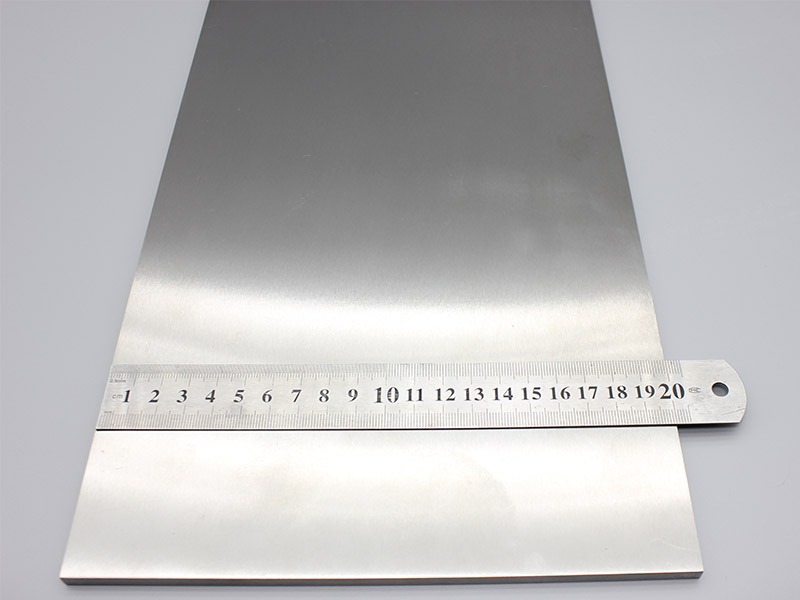

We need tungsten heavy alloy plates for counterweight applications. Please share available thickness...

Copyright © Zhuzhou Jiuding Metal Technology Co., Ltd. All Rights Reserved