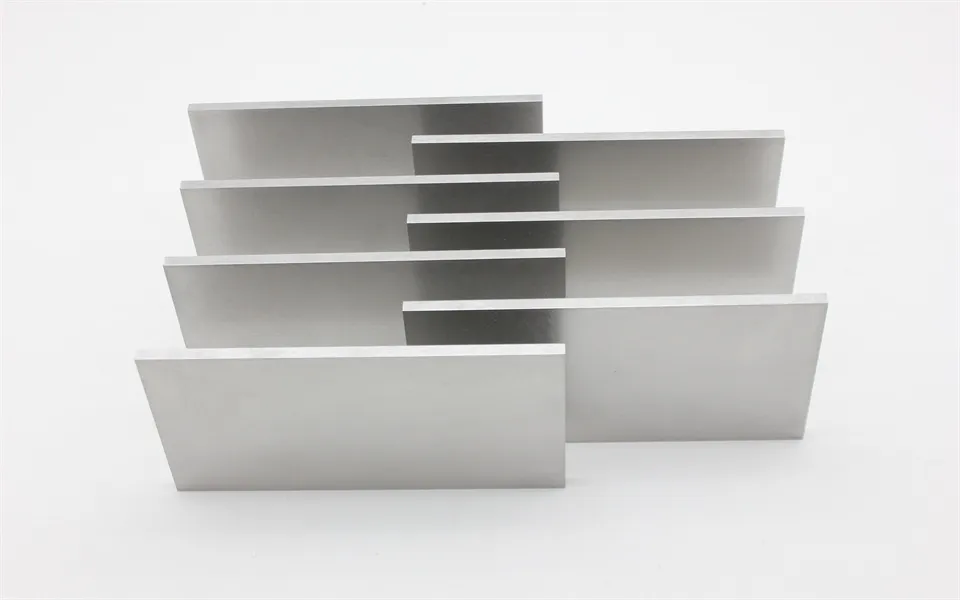

China tungsten heavy alloy pipes is designed for applications requiring maximum strength with minimal volume. The high density ensures the alloy has great balance and vibration resistance. The alloy has the same mechanical properties at elevated pressure, which is why it can be found in ballistic applications, commercial aerospace structures, and advanced tooling. China tungsten heavy alloy pipes is resistant to cracking, corrosion, and fatigue, so it can be employed in extreme working conditions.

In addition to strength, China tungsten heavy alloy pipes is also important to the medical and nuclear industries for radiation protection. The high atomic mass number provides exceptional shielding from gamma rays and x-rays. Hospitals utilize China tungsten heavy alloy pipes in CT scanners, collimators, and lead protective barrier panels. Nucleaer power facilities utilize China tungsten heavy alloy pipes in reactor shielding and shipping containers. The durability of the alloy allows the use of thinner mass while still achieving the same protection level, thereby offering efficient use of space and long-term reliability.

The increasing global focus on clean energy and smart materials will provide direction for future China tungsten heavy alloy pipes. It will be integrated into wind turbine systems, advanced weapons stabilization, and sustainable transportation methods. Designing hybrid alloys will improve performance and capability while incorporating environmental performance.

For machinery equipped with China tungsten heavy alloy pipes components, it is ideal to have a scheduled time to perform maintenance of the machinery. As part of planned maintenance, check the components for alignment and correct lubrication. When dust or residue is present, clean the surfaces regularly to adequately avoid abrasive wear. The parts must remain cool and dry for the alloy to properly maintain mechanical strength and to resist mechanical fatigue.

Due to its moderately high melting point combined with toughness, China tungsten heavy alloy pipes performs well under extreme conditions. Commonly it has uses in radiation shielding, medical devices, and military hardware. The strength and stability provided from China tungsten heavy alloy pipes make it an obvious choice for precision applications.

Q: What are the key mechanical properties of Tungsten heavy alloy? A: Tungsten heavy alloy offers high tensile strength, superior hardness, and outstanding resistance to fatigue, ensuring reliability in harsh environments. Q: How does Tungsten heavy alloy perform under extreme heat? A: It retains structural integrity and strength even at elevated temperatures, making it suitable for high-temperature engineering tasks. Q: Why is Tungsten heavy alloy favored for radiation shielding? A: Its high atomic mass and density allow it to effectively block radiation while maintaining structural strength. Q: Is Tungsten heavy alloy environmentally friendly? A: Yes, it is non-toxic and can be recycled efficiently, making it a sustainable material for long-term industrial use. Q: What are the typical compositions of Tungsten heavy alloy? A: It typically contains 90–98% tungsten combined with nickel, copper, or iron to enhance ductility and machinability.

I’ve used the tungsten jig for months, and its weight balance makes it super easy to control even in deep spots.

The tungsten jig feels incredibly durable — I’ve caught dozens of fish, and it still looks new.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

We are a machining parts supplier seeking tungsten heavy alloy rods for precision components. Kindly...

Our aerospace division is sourcing tungsten heavy alloy counterweights. Please confirm density, tole...

Copyright © Zhuzhou Jiuding Metal Technology Co., Ltd. All Rights Reserved