China tungsten heavy alloy tube has become an important material in industries manufacturing compact and lightweight yet robust items. Its tensile strength and relative flexibility provide good performance in aerospace devices and instruments, where precision is paramount. The heat-resistance and low thermal expansion of the alloy facilitate operational precision while minimizing deformation. It is also considered a high-performance option in rotating machinery experiencing high energy-translation speeds and mechanical vibration.

Because of density and strength, China tungsten heavy alloy tube are well-suited for precision machinery applications requiring precise balancing and vibration control. Examples include flywheels and dynamic dampers, as well as automotive applications for crankshaft weights or other components. {Keywords} absorb vibration, extends the life of machines, and improves performance when used in high speed operational conditions.

The future development of China tungsten heavy alloy tube will concentrate on higher thermal performance and greater sustainability in applications. It is expected that new production methods will reduce carbon emissions during processing, and innovations in micro-alloying will provide higher strength and fatigue resistance. Further incorporation into next-generation nuclear reactors and fusion will also continue.

The life of China tungsten heavy alloy tube is consistent with care and maintenance. Do not drop or strike it against hard surfaces, as even minor impressions will impact the balance and performance of the China tungsten heavy alloy tube. Transport and store in tightly sealed containers to protect China tungsten heavy alloy tube from humidity and airborne contaminants.

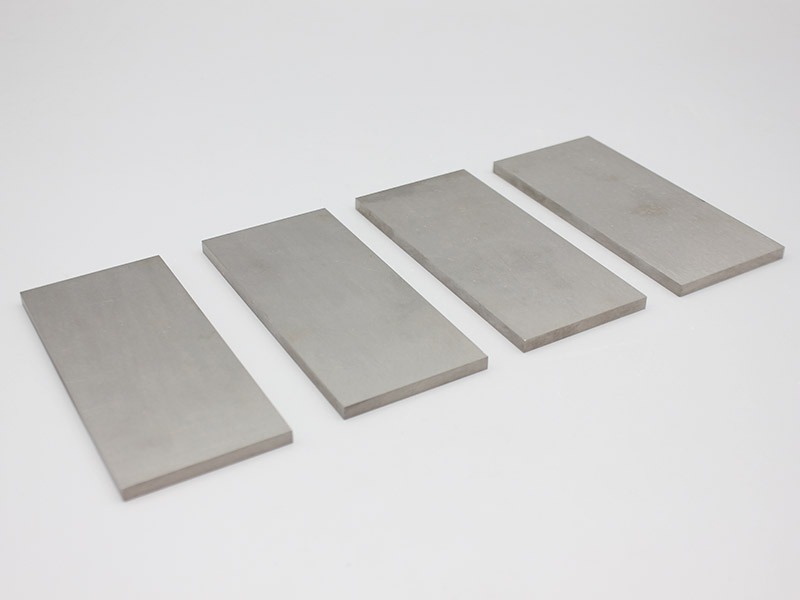

China tungsten heavy alloy tube is suitable for applications that require surface area weight and mechanical strength. The material maintains an excellent wear resistance and has a high thermal stability characteristic. It is commonly found in parts for aerospace balancing, in mold making, and in heavy engineering equipment. Because of its density, China tungsten heavy alloy tube provides the highest reliability and operational efficiency.

Q: What makes Tungsten heavy alloy essential in engineering applications? A: Tungsten heavy alloy is essential because of its exceptional density, hardness, and thermal stability, making it reliable for use in high-performance mechanical and structural components. Q: How is Tungsten heavy alloy produced? A: It is made through powder metallurgy, where tungsten powder is blended with nickel, iron, or copper and sintered at high temperatures to form a compact, durable alloy. Q: Why is Tungsten heavy alloy suitable for aerospace industries? A: Its superior weight distribution and resistance to thermal stress make it perfect for use in counterbalances, rotor systems, and aircraft control components. Q: Can Tungsten heavy alloy be machined easily? A: While it is very dense and hard, it can be precisely machined using specialized tools designed for high-strength materials. Q: In which fields is Tungsten heavy alloy commonly applied? A: It is widely used in defense, medical imaging, oil drilling, aerospace, and industrial balancing systems.

The tungsten jig feels incredibly durable — I’ve caught dozens of fish, and it still looks new.

The Tungsten heavy alloy provides solid consistency in production; every piece meets our exact requirements.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

Could you provide your latest price list and production capacity for tungsten heavy alloy bars? We p...

We are looking for high-density tungsten jig for our upcoming fishing gear line. Could you please se...

Copyright © Zhuzhou Jiuding Metal Technology Co., Ltd. All Rights Reserved