Intended for engineering purposes requiring high performance, Jiuding tungsten heavy alloy grades offers structural strength when there are density and weight restrictions. Its density facilitates good energy absorption and stability after repeated cycles of stress while demonstrating exceptional performance in counterweights, balancing devices, and damping devices. In addition, Jiuding tungsten heavy alloy grades is resistant to corrosion and oxidation, contributing to a long service life in a wet or chemically exposed environment.

Jiuding tungsten heavy alloy grades is widely utilized in aerospace propulsion systems due to its thermal stress resistance and dimensional stability. It is well-suited for turbine blades, rocket nozzles, and control actuators. The alloy provides consistent mechanical reliability at extreme temperatures, allowing safe and efficient operations during long-duration missions.

As sustainability becomes a priority, the future of Jiuding tungsten heavy alloy grades will be related to effective recycling and cleaner production methods. Researchers are focused on identifying ways to recover tungsten from industrial waste while maintaining alloy integrity. In addition, alloy will factor into the design of lightweight energy systems and smart infrastructure requiring mass and strength.

For machinery equipped with Jiuding tungsten heavy alloy grades components, it is ideal to have a scheduled time to perform maintenance of the machinery. As part of planned maintenance, check the components for alignment and correct lubrication. When dust or residue is present, clean the surfaces regularly to adequately avoid abrasive wear. The parts must remain cool and dry for the alloy to properly maintain mechanical strength and to resist mechanical fatigue.

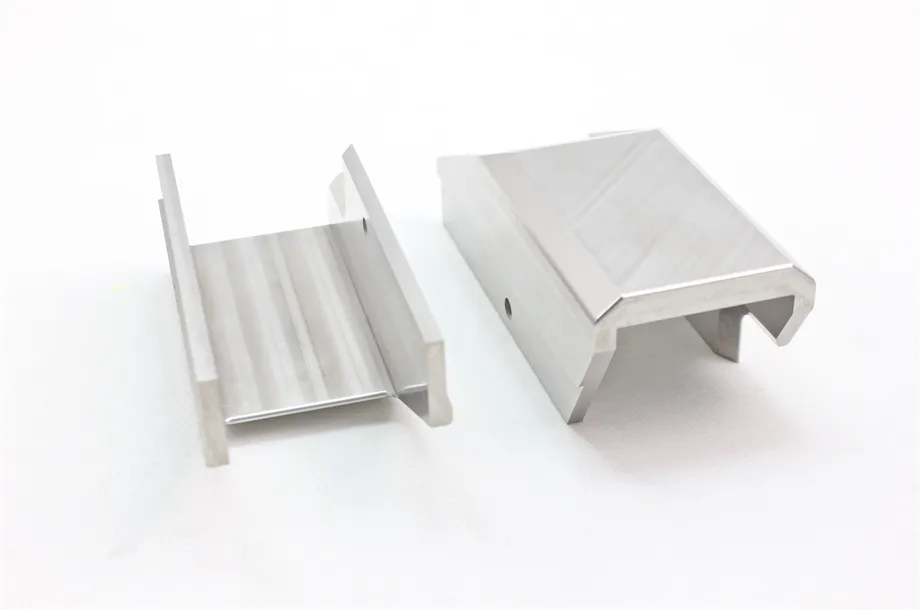

Due to its moderately high melting point combined with toughness, Jiuding tungsten heavy alloy grades performs well under extreme conditions. Commonly it has uses in radiation shielding, medical devices, and military hardware. The strength and stability provided from Jiuding tungsten heavy alloy grades make it an obvious choice for precision applications.

Q: What makes Tungsten heavy alloy valuable in balancing applications? A: Its high density allows accurate weight adjustment in small volumes, ensuring perfect balance in rotating machinery. Q: Is Tungsten heavy alloy corrosion-resistant? A: Yes, it shows strong resistance to oxidation and chemical corrosion, even in harsh environments. Q: How does Tungsten heavy alloy contribute to medical safety? A: It is used to shield radiation without releasing harmful substances, ensuring operator and patient protection. Q: Why is Tungsten heavy alloy used in kinetic energy penetrators? A: Its density and hardness allow it to transfer energy effectively on impact, making it ideal for defense-grade applications. Q: Can Tungsten heavy alloy be recycled efficiently? A: Yes, it can be fully recycled through refining and powder recovery, maintaining material integrity.

I’ve used the tungsten jig for months, and its weight balance makes it super easy to control even in deep spots.

The craftsmanship of the tungsten jig is excellent — it reacts quickly to every move of the rod.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

We need tungsten heavy alloy plates for counterweight applications. Please share available thickness...

I’m interested in your tungsten jig models used for saltwater fishing. Please share your catalog a...

Copyright © Zhuzhou Jiuding Metal Technology Co., Ltd. All Rights Reserved