The heavy composition of Jiuding tungsten heavy alloy material usually contributes to excellent mechanical equilibrium and also energy transfer capability. The there being a good microstructure the material becomes not only more durable but less prone to failing even if the demand is for cyclic loading. Industries count on its stability for the making of gyroscopes, flywheels, and precision molds. The mix of density and non-corrosive nature makes Jiuding tungsten heavy alloy material the right choice for the locations where the operations are either in the sea or at high temperatures, thus, the performance continuity for the demanding industrial tasks is assured.

Because of density and strength, Jiuding tungsten heavy alloy material are well-suited for precision machinery applications requiring precise balancing and vibration control. Examples include flywheels and dynamic dampers, as well as automotive applications for crankshaft weights or other components. {Keywords} absorb vibration, extends the life of machines, and improves performance when used in high speed operational conditions.

The future development of Jiuding tungsten heavy alloy material will concentrate on higher thermal performance and greater sustainability in applications. It is expected that new production methods will reduce carbon emissions during processing, and innovations in micro-alloying will provide higher strength and fatigue resistance. Further incorporation into next-generation nuclear reactors and fusion will also continue.

After each operational activity, Jiuding tungsten heavy alloy material must be cleaned and thoroughly dried. Application of a thin film of oil will help enhance corrosion resistance. Store in locations away from the sun and chemicals that promote corrosion, in order to maintain observable mechanical properties and original density characteristics of the Jiuding tungsten heavy alloy material.

Jiuding tungsten heavy alloy material provides weight efficiency with thermal management in advanced engineered systems. The dense character of the material provides mechanical stability and vibration control. Due to its density, Jiuding tungsten heavy alloy material is very likely to be encountered in precision machines, components of missiles, and other engineering systems.

Q: What are the key mechanical properties of Tungsten heavy alloy? A: Tungsten heavy alloy offers high tensile strength, superior hardness, and outstanding resistance to fatigue, ensuring reliability in harsh environments. Q: How does Tungsten heavy alloy perform under extreme heat? A: It retains structural integrity and strength even at elevated temperatures, making it suitable for high-temperature engineering tasks. Q: Why is Tungsten heavy alloy favored for radiation shielding? A: Its high atomic mass and density allow it to effectively block radiation while maintaining structural strength. Q: Is Tungsten heavy alloy environmentally friendly? A: Yes, it is non-toxic and can be recycled efficiently, making it a sustainable material for long-term industrial use. Q: What are the typical compositions of Tungsten heavy alloy? A: It typically contains 90–98% tungsten combined with nickel, copper, or iron to enhance ductility and machinability.

The tungsten jig feels incredibly durable — I’ve caught dozens of fish, and it still looks new.

I appreciate that Tungsten heavy alloy is non-toxic yet just as heavy and stable as lead — a smart upgrade.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

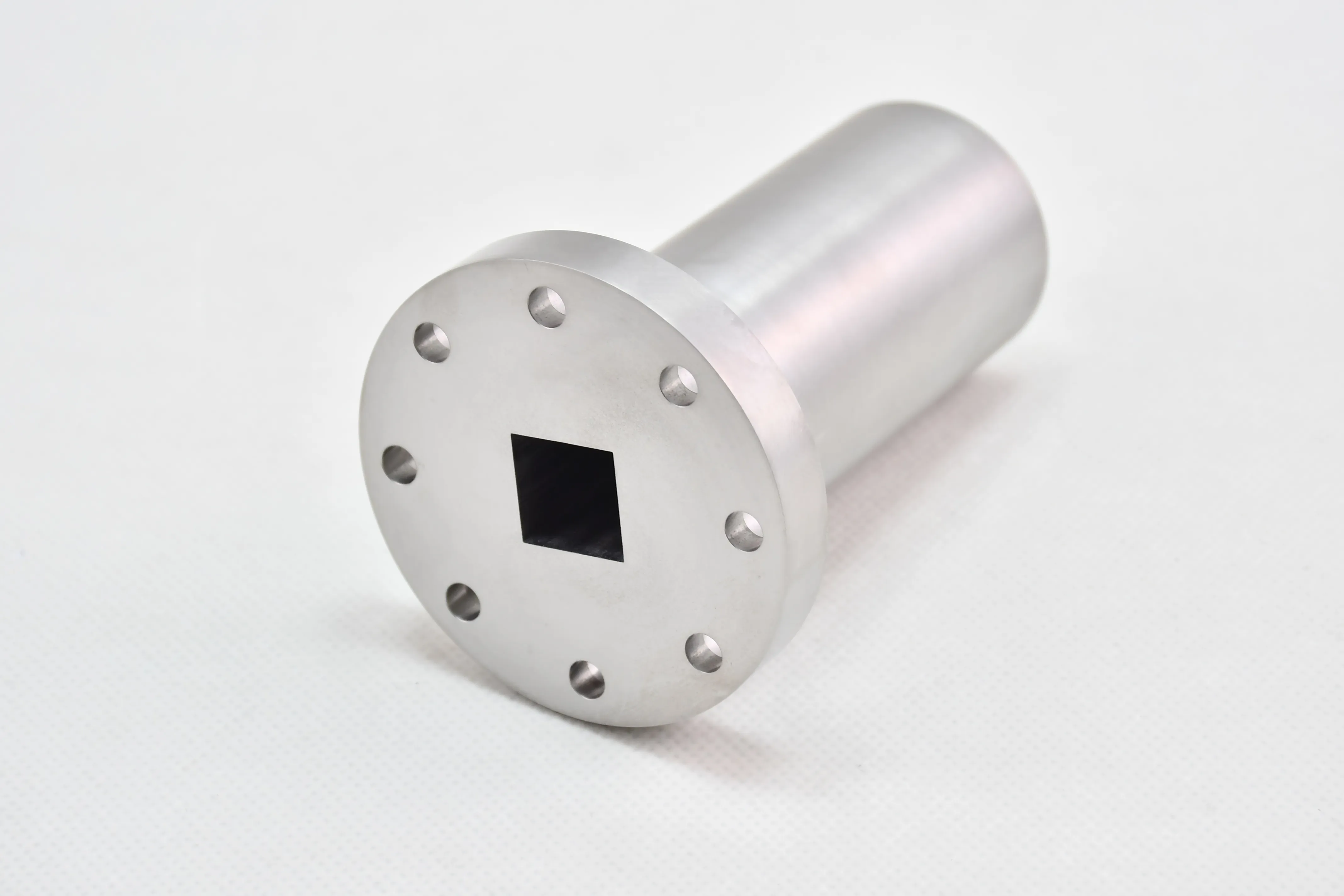

We are interested in tungsten heavy alloy cylinders for kinetic energy applications. Could you send ...

We operate a fishing tackle store and want to stock tungsten jig. Please send details on bulk pricin...

Copyright © Zhuzhou Jiuding Metal Technology Co., Ltd. All Rights Reserved