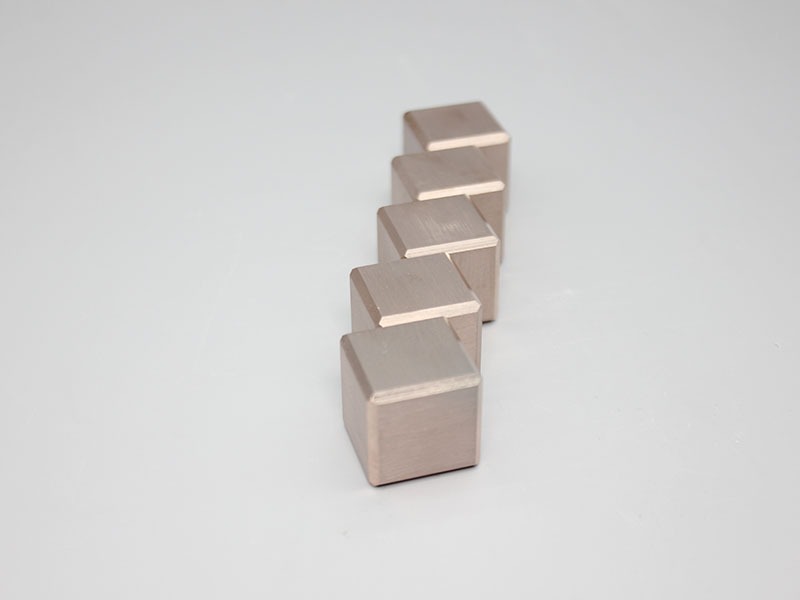

Jiuding tungsten heavy alloy plate gives the advantage of being extremely hard and at the same time readily machinable, thus providing excellent resistance to both wear and impact. It finds application in military, aerospace, and medical industries for parts which are exposed to the forces of vibration, radiation, and so on. The material's uniform density is the reason for predictable behavior which in turn is the basis for engineers to make smaller yet stronger components that will work reliably in difficult operational conditions.

In marine engineering, Jiuding tungsten heavy alloy plate is utilized for ballast weights, propeller balancing, and other underwater applications. The high density of the material allows for compact designs, and the corrosion-resistant properties of the material allow for performance in salt water environments. Submarine systems incorporate the alloy for stability to allow for ease of maneuverability and control of depth.

In the following years expect a confluence of Jiuding tungsten heavy alloy plate with advanced composites for hybrid engineered materials. The hybrids will provide flexibility, corrosion resistance and weight reduction benefits. In addition, as industries look for stable and energy absorbing materials, the role of alloy in electric mobility and autonomous vehicles will grow.

After each operational activity, Jiuding tungsten heavy alloy plate must be cleaned and thoroughly dried. Application of a thin film of oil will help enhance corrosion resistance. Store in locations away from the sun and chemicals that promote corrosion, in order to maintain observable mechanical properties and original density characteristics of the Jiuding tungsten heavy alloy plate.

Jiuding tungsten heavy alloy plate provides weight efficiency with thermal management in advanced engineered systems. The dense character of the material provides mechanical stability and vibration control. Due to its density, Jiuding tungsten heavy alloy plate is very likely to be encountered in precision machines, components of missiles, and other engineering systems.

Q: What are the key mechanical properties of Tungsten heavy alloy? A: Tungsten heavy alloy offers high tensile strength, superior hardness, and outstanding resistance to fatigue, ensuring reliability in harsh environments. Q: How does Tungsten heavy alloy perform under extreme heat? A: It retains structural integrity and strength even at elevated temperatures, making it suitable for high-temperature engineering tasks. Q: Why is Tungsten heavy alloy favored for radiation shielding? A: Its high atomic mass and density allow it to effectively block radiation while maintaining structural strength. Q: Is Tungsten heavy alloy environmentally friendly? A: Yes, it is non-toxic and can be recycled efficiently, making it a sustainable material for long-term industrial use. Q: What are the typical compositions of Tungsten heavy alloy? A: It typically contains 90–98% tungsten combined with nickel, copper, or iron to enhance ductility and machinability.

I’ve used the tungsten jig for months, and its weight balance makes it super easy to control even in deep spots.

The Tungsten heavy alloy handles extreme pressure and heat better than most metals I’ve used.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

I’m interested in your tungsten jig models used for saltwater fishing. Please share your catalog a...

We need tungsten heavy alloy plates for counterweight applications. Please share available thickness...

Copyright © Zhuzhou Jiuding Metal Technology Co., Ltd. All Rights Reserved