Intended for engineering purposes requiring high performance, Jiuding tungsten silver alloy offers structural strength when there are density and weight restrictions. Its density facilitates good energy absorption and stability after repeated cycles of stress while demonstrating exceptional performance in counterweights, balancing devices, and damping devices. In addition, Jiuding tungsten silver alloy is resistant to corrosion and oxidation, contributing to a long service life in a wet or chemically exposed environment.

In marine engineering, Jiuding tungsten silver alloy is utilized for ballast weights, propeller balancing, and other underwater applications. The high density of the material allows for compact designs, and the corrosion-resistant properties of the material allow for performance in salt water environments. Submarine systems incorporate the alloy for stability to allow for ease of maneuverability and control of depth.

As an industry advances to increasingly perform better, Jiuding tungsten silver alloy will see great depth of use in precision control systems, drones, and renewable power generation applications. Researchers are evolving sintering techniques that reduce material size and provide better designs based on fatigue criteria while being lightweight.

The life of Jiuding tungsten silver alloy is consistent with care and maintenance. Do not drop or strike it against hard surfaces, as even minor impressions will impact the balance and performance of the Jiuding tungsten silver alloy. Transport and store in tightly sealed containers to protect Jiuding tungsten silver alloy from humidity and airborne contaminants.

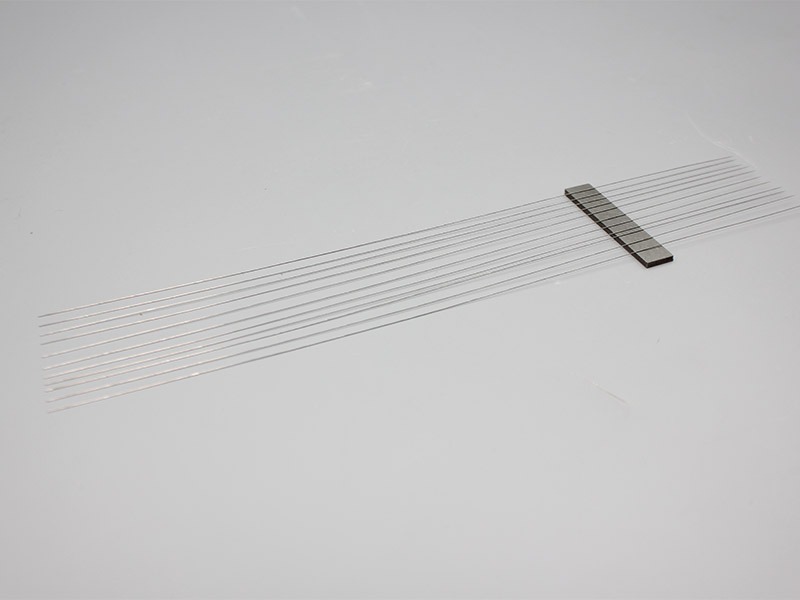

Jiuding tungsten silver alloy is specifically designed for high performance applications, combining hardness with good machinability. Common applications include for counter weights, ballistic applications, and vibration damping structures. The consistent physical properties of the material provide a high level of precision and durability in a final product.

Q: How is Tungsten heavy alloy used in oil and gas exploration? A: It serves as a key material for counterweights, drilling tools, and downhole equipment due to its density and wear resistance. Q: What maintenance practices help preserve Tungsten heavy alloy components? A: Regular cleaning, controlled storage, and protection from moisture help prevent oxidation and extend service life. Q: Why does Tungsten heavy alloy perform well in vibration control? A: Its density and internal damping capacity reduce oscillations in precision machinery and aerospace systems. Q: What machining techniques are best for Tungsten heavy alloy? A: CNC milling, grinding, and electrical discharge machining are commonly used for shaping Tungsten heavy alloy with precision. Q: How does Tungsten heavy alloy support environmental sustainability? A: It replaces toxic lead in many applications while offering durability and recyclability for eco-friendly production cycles.

The tungsten jig feels incredibly durable — I’ve caught dozens of fish, and it still looks new.

I’ve worked with Tungsten heavy alloy materials for years, and they never disappoint in precision or reliability.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

Could you provide your latest price list and production capacity for tungsten heavy alloy bars? We p...

Do you provide OEM service for tungsten jig? We’d like to customize colors and hook types for our ...

Copyright © Zhuzhou Jiuding Metal Technology Co., Ltd. All Rights Reserved