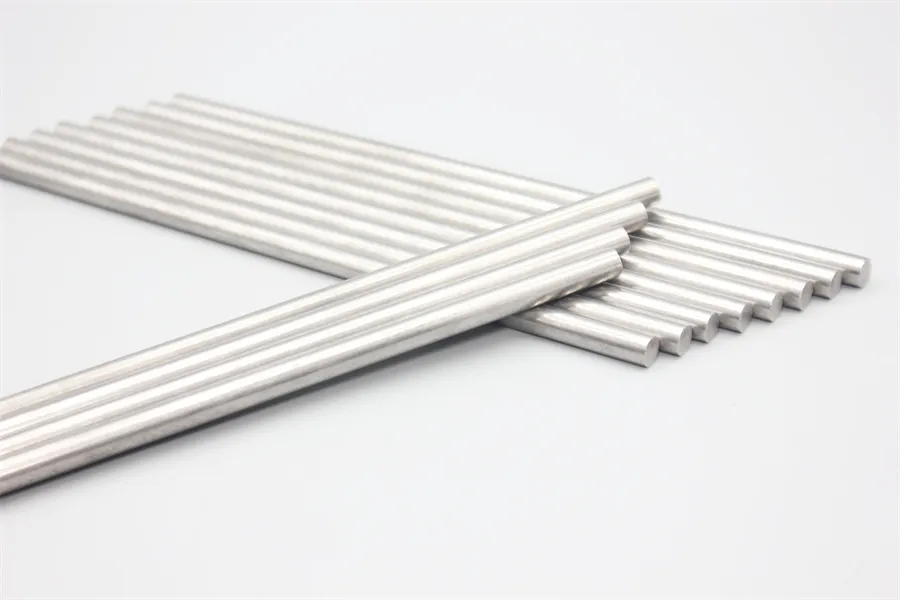

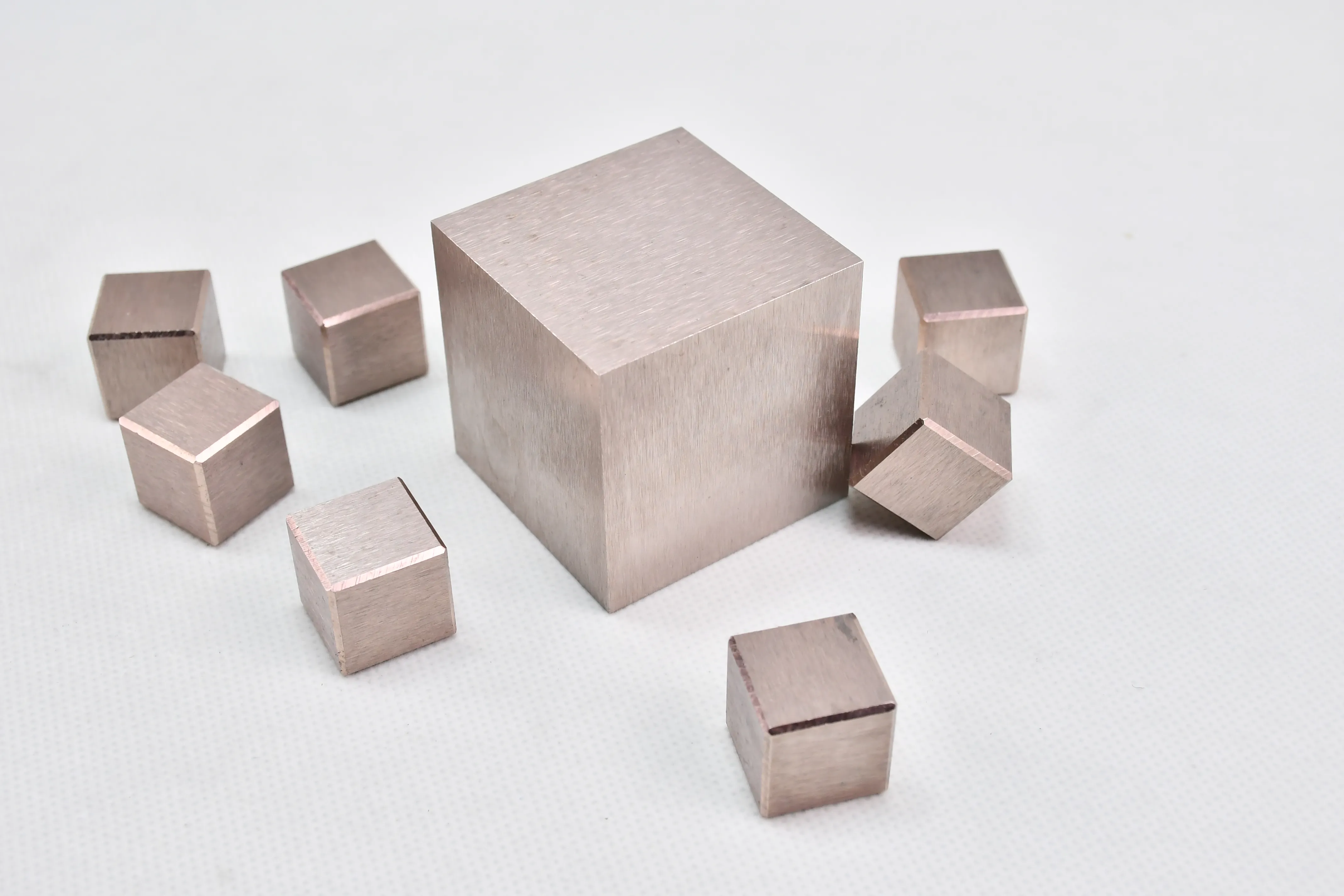

copper tungsten sheet manufacturer are taking advantage of contemporary metallurgical technology to create tungsten heavy alloys with exceptional density and impact strength. Their alloys have become known for their stability, machinability, and durability. The entire product line undergoes precision-controlled sintering and post-processing, to ensure processing quality. copper tungsten sheet manufacturer are constantly increasing their production capacity to be able to supply the global market with sophisticated tungsten products.

copper tungsten sheet manufacturer are the producers of tungsten heavy alloys that are critical in engineering and medical applications. They are the ones used for shielding, balancing, and tooling where compact mass and resistance to deformation are the most important features. The knowledge of copper tungsten sheet manufacturer in alloy blending guarantees that each product provides the qualities of stability, longevity, and precision performance even under the stress of operational conditions.

While the industries are transforming themselves by using lighter but tougher materials, copper tungsten sheet manufacturer will most likely resort to AI-based design and smart manufacturing systems. Real-time monitoring of the consistency of the alloy and its mechanical behavior will be made possible by these innovations. Sustainability will be the main emphasis of future development, thereby recycling technologies cutting down on raw material waste but still keeping the structural excellence of tungsten heavy alloys.

copper tungsten sheet manufacturer propose the cleaning and the surface treatment of tungsten heavy alloy components as a maintenance strategy. Do not use polishing materials that are abrasive as they might leave scratches on the surface of the alloy. Components, when not in use, should be wrapped in corrosion-resistant materials and stored in low-humidity areas. Preventive maintenance guarantees that the alloy will continue to perform consistently and at the same time, it will not lose its strength microstructurally.

copper tungsten sheet manufacturer have built a solid reputation in the metalworking industry due to their proficiency in tungsten heavy alloy production. They merge advanced metallurgy with precise engineering to create materials that are guaranteed to perform consistently even in the most demanding conditions. copper tungsten sheet manufacturer serve clients in the defense, medical, and aerospace industries, and they reinforce the concepts of reliability, consistency, and strength in every alloy they produce.

Q: What are the typical density ranges of Tungsten heavy alloy? A: It typically ranges between 17.0 and 18.8 g/cm³, providing unmatched weight and compactness for engineering designs. Q: Why is Tungsten heavy alloy used in high-impact tools? A: Its toughness and ability to resist cracking make it perfect for tools that endure strong impacts or vibration. Q: How does Tungsten heavy alloy behave in corrosive settings? A: It resists most chemical reactions, maintaining its properties in acidic or humid industrial environments. Q: What finishing methods are applied to Tungsten heavy alloy? A: Polishing and coating are often used to enhance surface quality and prevent oxidation. Q: How is Tungsten heavy alloy expected to evolve in the future? A: New manufacturing methods will focus on higher efficiency, recyclability, and improved microstructure control.

The tungsten jig performs great in both saltwater and freshwater; it doesn’t rust or wear out easily.

What I love about the tungsten jig is how fast it sinks and how naturally it moves in the water.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

Could you provide info about your heavy-duty tungsten jig types suitable for deep-sea fishing? Looki...

We operate a fishing tackle store and want to stock tungsten jig. Please send details on bulk pricin...

Copyright © Zhuzhou Jiuding Metal Technology Co., Ltd. All Rights Reserved