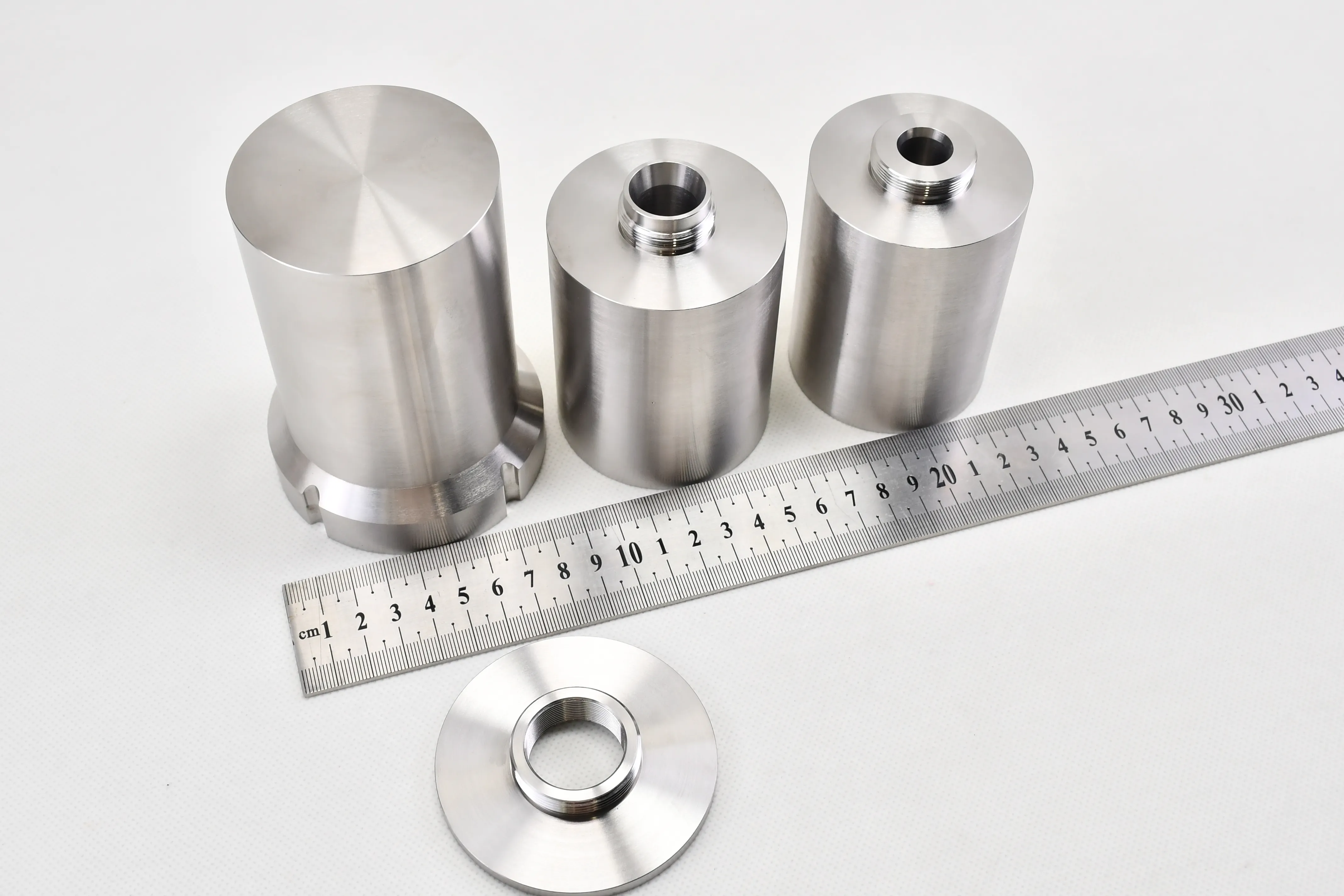

wnife manufacturer are concentrating on the production of tungsten heavy alloys that deliver the highest mechanical stability and the most uniform density. The alloys, in turn, have high resistance to wear, oxidation, and deformation. Under the conditions of advanced powder metallurgy and vacuum sintering, wnife manufacturer obtain the highest accuracy in weight control and obtain the uniformity of the material. The aforementioned characteristics are the reason why their alloys are preferred in precision components for defense, aerospace, and industrial manufacturing.

wnife manufacturer’s tungsten heavy alloys are the major factor in modern engineering, particularly if an area-saving design and high mass concentration are the requirements. They are found in ship ballast, aerospace stabilizers, and earthquake shock absorbers. With the strict control of the alloy features, wnife manufacturer are confident of the performance extending to both the civilian and military fields.

The wnife manufacturer will be able to push the development frontiers of Tungsten Heavy Alloys into the areas of the electric car and fusion energy industries thanks to technological improvements. Better machining, even distribution of density, and greater resistance to recurrent stress will make the material more usable. Moreover, constant R&D funding will guarantee the manufacturers’ presence in the global advanced materials market as an important player.

wnife manufacturer advise setting up a maintenance plan for tungsten heavy alloy tooling that is regular. Material longevity is greatly increased if cleaned, dried, and given protective films after moisture exposure. Avoiding rapid temperature changes between the heated part and its surroundings is an operation that may cause stress inside. Monitoring of materials is done consistently so that every part maintains its stability in terms of structure and performance.

wnife manufacturer produce tungsten heavy alloys that are tailored to resist high stress and impacts. The company’s production systems merge state-of-the-art technology and thorough quality inspection. These materials are geared to take the place of conventional metals in applications where a combination of high density and wear resistance is required. wnife manufacturer continue to be a reliable supplier for industries that demand the highest standards in both material performance and manufacturing precision.

Q: How does Tungsten heavy alloy handle thermal expansion? A: It has a low coefficient of thermal expansion, ensuring dimensional stability under temperature fluctuations. Q: What benefits does Tungsten heavy alloy bring to electronics? A: Its thermal conductivity and durability make it suitable for heat sinks and electrical contact applications. Q: Why is Tungsten heavy alloy preferred for precision machining? A: It provides excellent dimensional accuracy and maintains balance even after extended mechanical use. Q: How can Tungsten heavy alloy components be cleaned safely? A: Use mild, non-corrosive cleaners and soft materials to remove residue without damaging the surface. Q: What industries continue to expand the use of Tungsten heavy alloy? A: Aerospace, medical, defense, and renewable energy sectors increasingly rely on it for performance-critical parts.

I appreciate that Tungsten heavy alloy is non-toxic yet just as heavy and stable as lead — a smart upgrade.

I’ve used the tungsten jig for months, and its weight balance makes it super easy to control even in deep spots.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

Could you provide info about your heavy-duty tungsten jig types suitable for deep-sea fishing? Looki...

Do you provide OEM service for tungsten jig? We’d like to customize colors and hook types for our ...

Copyright © Zhuzhou Jiuding Metal Technology Co., Ltd. All Rights Reserved