machining copper tungsten manufacturer guarantee that tungsten heavy alloys will be produced with the strictest metallurgical standards. Their products are even able to do incredible things in areas where the precise mass distribution as well as impact control are essential. The machining copper tungsten manufacturer company uses advanced sintering systems and produces alloys that not only have high mechanial-strength but also have no thermal reliability issues which thus are widely used in the field.

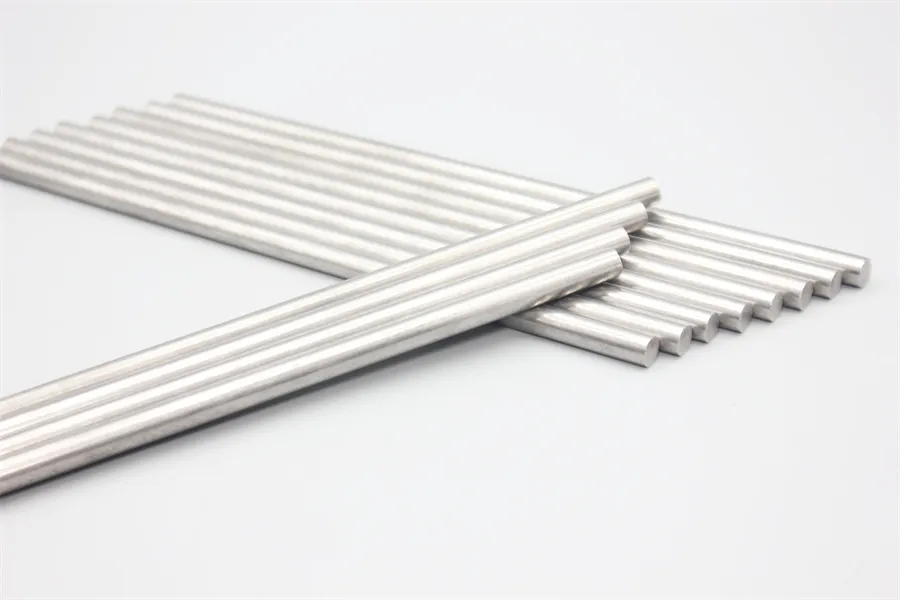

machining copper tungsten manufacturer are the producers of tungsten heavy alloys that are critical in engineering and medical applications. They are the ones used for shielding, balancing, and tooling where compact mass and resistance to deformation are the most important features. The knowledge of machining copper tungsten manufacturer in alloy blending guarantees that each product provides the qualities of stability, longevity, and precision performance even under the stress of operational conditions.

The future path of machining copper tungsten manufacturer is going to be characterized by precision customization and eco-friendly manufacturing practices. It is anticipated that the producers will use sintering techniques that emit low toxins as well as rely on green energy for their production lines. The investigation into micro-grain alloying will eventually lead to the discovery of alloys that have superior fatigue resistance thus enabling tungsten materials to meet the challenges of operating in more difficult and complex environments.

For reliability over the long term, machining copper tungsten manufacturer suggest that tungsten heavy alloy products be placed on non-reactive surfaces and kept away from moisture to avoid condensation. Ultrasonic inspection on a periodic basis can uncover hidden fatigue or microfractures. Always use neutral pH solutions for cleaning. By adhering to these practices, the manufacturers and the end-users of the metal are able to retain its strength and accuracy against harsh conditions for a long time.

machining copper tungsten manufacturer have built a solid reputation in the metalworking industry due to their proficiency in tungsten heavy alloy production. They merge advanced metallurgy with precise engineering to create materials that are guaranteed to perform consistently even in the most demanding conditions. machining copper tungsten manufacturer serve clients in the defense, medical, and aerospace industries, and they reinforce the concepts of reliability, consistency, and strength in every alloy they produce.

Q: Why is Tungsten heavy alloy used in precision instruments? A: Its dimensional stability and mass make it perfect for counterweights and vibration control in sensitive devices. Q: How does Tungsten heavy alloy enhance radiation safety? A: It blocks radiation efficiently without increasing volume, protecting both users and surrounding equipment. Q: Can Tungsten heavy alloy be shaped into complex geometries? A: Yes, it can be formed into intricate designs using powder metallurgy and advanced machining techniques. Q: What environmental conditions can Tungsten heavy alloy withstand? A: It performs reliably under high pressure, moisture, and chemical exposure without corrosion or deformation. Q: How is Tungsten heavy alloy contributing to modern engineering? A: It supports high-performance manufacturing, offering strength, precision, and sustainability across industries.

The Tungsten heavy alloy handles extreme pressure and heat better than most metals I’ve used.

What I love about the tungsten jig is how fast it sinks and how naturally it moves in the water.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

We are looking for high-density tungsten jig for our upcoming fishing gear line. Could you please se...

We need tungsten heavy alloy plates for counterweight applications. Please share available thickness...

Copyright © Zhuzhou Jiuding Metal Technology Co., Ltd. All Rights Reserved