tungsten heavy alloy manufacturers are highlighted by their precision manufacturing and technical know-how. The production of their tungsten heavy alloys is through mixing and sintering processes that are advanced and result in nano-size microstructures. It means stabling of both physical and mechanical properties. Continuous quality control at tungsten heavy alloy manufacturers ensures that the product has strength, density and corrosion resistance, thus giving the reliable performance of their alloys in tough industrial environments.

tungsten heavy alloy manufacturers are the main source of tungsten heavy alloys which are largely applied in manufacturing medical imaging equipment and building radiation protection structures. The weightiness of the alloys provides a way to block the radiations efficiently and thus, they are considered for X-ray and CT scanner shielding. tungsten heavy alloy manufacturers are still making changes in their alloy composition to improve strength and machinability for special applications.

The tungsten heavy alloy manufacturers will be able to push the development frontiers of Tungsten Heavy Alloys into the areas of the electric car and fusion energy industries thanks to technological improvements. Better machining, even distribution of density, and greater resistance to recurrent stress will make the material more usable. Moreover, constant R&D funding will guarantee the manufacturers’ presence in the global advanced materials market as an important player.

For the tungsten heavy alloys from tungsten heavy alloy manufacturers to maintain durability, they will need to undergo routine inspections. Users will have to watch for surface damages, pitting, or under stress caused deformations. The finish will be protected by gentle brushing and non-acidic cleaning agents. Regularly lubricating the alloy-based components will reduce wear thus stabilizing the metal in severe industrial conditions.

tungsten heavy alloy manufacturers have made their name in the manufacturing of tungsten heavy alloys that are outstanding in terms of density and mechanical strength. These materials can endure very high mechanical stress and even corrosive environments. The professionals at tungsten heavy alloy manufacturers apply cutting-edge machining and blending methods which allow them to have very precise control over the alloy's composition. These alloys are indispensable in the sectors of industrial, military, and medical equipment, which demand moderate mass and strength even under extreme conditions.

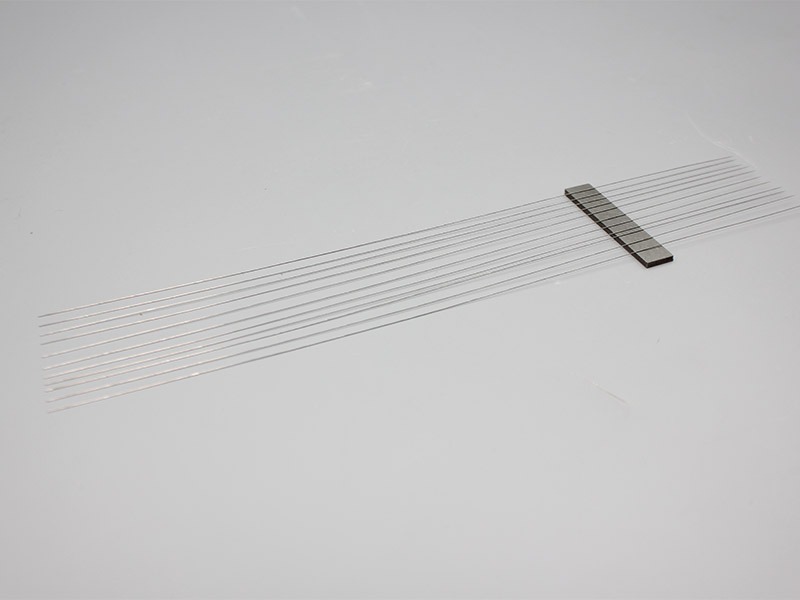

Q: Why is Tungsten heavy alloy used in precision instruments? A: Its dimensional stability and mass make it perfect for counterweights and vibration control in sensitive devices. Q: How does Tungsten heavy alloy enhance radiation safety? A: It blocks radiation efficiently without increasing volume, protecting both users and surrounding equipment. Q: Can Tungsten heavy alloy be shaped into complex geometries? A: Yes, it can be formed into intricate designs using powder metallurgy and advanced machining techniques. Q: What environmental conditions can Tungsten heavy alloy withstand? A: It performs reliably under high pressure, moisture, and chemical exposure without corrosion or deformation. Q: How is Tungsten heavy alloy contributing to modern engineering? A: It supports high-performance manufacturing, offering strength, precision, and sustainability across industries.

The Tungsten heavy alloy handles extreme pressure and heat better than most metals I’ve used.

The tungsten jig performs great in both saltwater and freshwater; it doesn’t rust or wear out easily.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

We are interested in tungsten heavy alloy cylinders for kinetic energy applications. Could you send ...

We are looking for high-density tungsten jig for our upcoming fishing gear line. Could you please se...

Copyright © Zhuzhou Jiuding Metal Technology Co., Ltd. All Rights Reserved