pure tungsten manufacturer are taking advantage of contemporary metallurgical technology to create tungsten heavy alloys with exceptional density and impact strength. Their alloys have become known for their stability, machinability, and durability. The entire product line undergoes precision-controlled sintering and post-processing, to ensure processing quality. pure tungsten manufacturer are constantly increasing their production capacity to be able to supply the global market with sophisticated tungsten products.

pure tungsten manufacturer create tungsten heavy alloys for the production of counterweights, inertial masses, and kinetic energy penetrators. The alloys can endure the extreme mechanical loads without losing their characteristics which makes them suitable for aerospace and defense applications. The accurate density control that comes with pure tungsten manufacturer leads to better performance of complex dynamic systems.

While the industries are transforming themselves by using lighter but tougher materials, pure tungsten manufacturer will most likely resort to AI-based design and smart manufacturing systems. Real-time monitoring of the consistency of the alloy and its mechanical behavior will be made possible by these innovations. Sustainability will be the main emphasis of future development, thereby recycling technologies cutting down on raw material waste but still keeping the structural excellence of tungsten heavy alloys.

pure tungsten manufacturer suggest non-reactive oils or lubricants as a means of protection throughout storage and transportation. Moreover, alcohol cleaning is necessary before installation in order to get rid of residues. Discolouration and crevice fatigue tests for high-temperature or radiation exposed parts are to be done periodically to assure quality and reliability over time.

pure tungsten manufacturer is a company that primarily deals with the research and manufacture of tungsten-based materials, which are heavy yet still possess great mechanical properties. The engineers are very aware of the demanding application areas and thus the production of counterweights, kinetic energy penetrators, and shielding components are just a few to name. All this is achieved through continuous research and upgraded processing technology, which by the way keeps the standards of global engineering markets for their products as they have uniform density, superior hardness, and high resistance to wear.

Q: Why is Tungsten heavy alloy used in precision instruments? A: Its dimensional stability and mass make it perfect for counterweights and vibration control in sensitive devices. Q: How does Tungsten heavy alloy enhance radiation safety? A: It blocks radiation efficiently without increasing volume, protecting both users and surrounding equipment. Q: Can Tungsten heavy alloy be shaped into complex geometries? A: Yes, it can be formed into intricate designs using powder metallurgy and advanced machining techniques. Q: What environmental conditions can Tungsten heavy alloy withstand? A: It performs reliably under high pressure, moisture, and chemical exposure without corrosion or deformation. Q: How is Tungsten heavy alloy contributing to modern engineering? A: It supports high-performance manufacturing, offering strength, precision, and sustainability across industries.

What I love about the tungsten jig is how fast it sinks and how naturally it moves in the water.

The craftsmanship of the tungsten jig is excellent — it reacts quickly to every move of the rod.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

Do you provide OEM service for tungsten jig? We’d like to customize colors and hook types for our ...

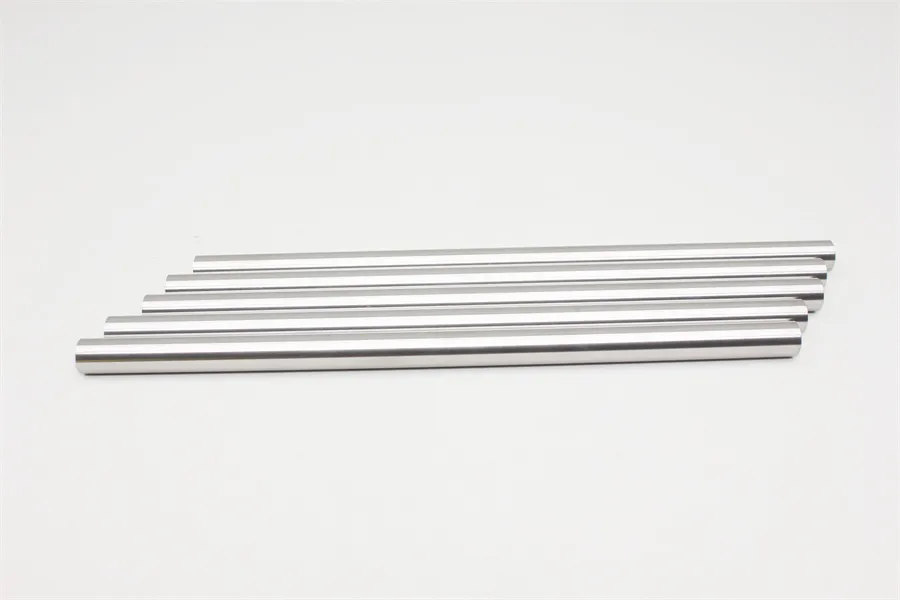

We are interested in tungsten heavy alloy cylinders for kinetic energy applications. Could you send ...

Copyright © Zhuzhou Jiuding Metal Technology Co., Ltd. All Rights Reserved