pure tungsten price manufacturer make use of cutting-edge technology in manufacturing to make sure that their tungsten heavy alloys attain not only structural integrity but also the best surface finish. Every product is purposely made for performance in extreme situations. pure tungsten price manufacturer conduct monitoring at all production levels to obtain a uniform microstructure and to preserve the desired physical properties for the specified industries.

pure tungsten price manufacturer create tungsten heavy alloys for the production of counterweights, inertial masses, and kinetic energy penetrators. The alloys can endure the extreme mechanical loads without losing their characteristics which makes them suitable for aerospace and defense applications. The accurate density control that comes with pure tungsten price manufacturer leads to better performance of complex dynamic systems.

In the wake of global engineering striving for efficiency and sustainability, pure tungsten price manufacturer are very likely to create cutting-edge tungsten alloys which are both high-performing and fully recyclable. The quality control supported by AI and the bonding technology will work together to eliminate inconsistency, thus making tungsten materials a solid supporter for the innovations in defense, aerospace, and renewable energy sectors.

For reliability over the long term, pure tungsten price manufacturer suggest that tungsten heavy alloy products be placed on non-reactive surfaces and kept away from moisture to avoid condensation. Ultrasonic inspection on a periodic basis can uncover hidden fatigue or microfractures. Always use neutral pH solutions for cleaning. By adhering to these practices, the manufacturers and the end-users of the metal are able to retain its strength and accuracy against harsh conditions for a long time.

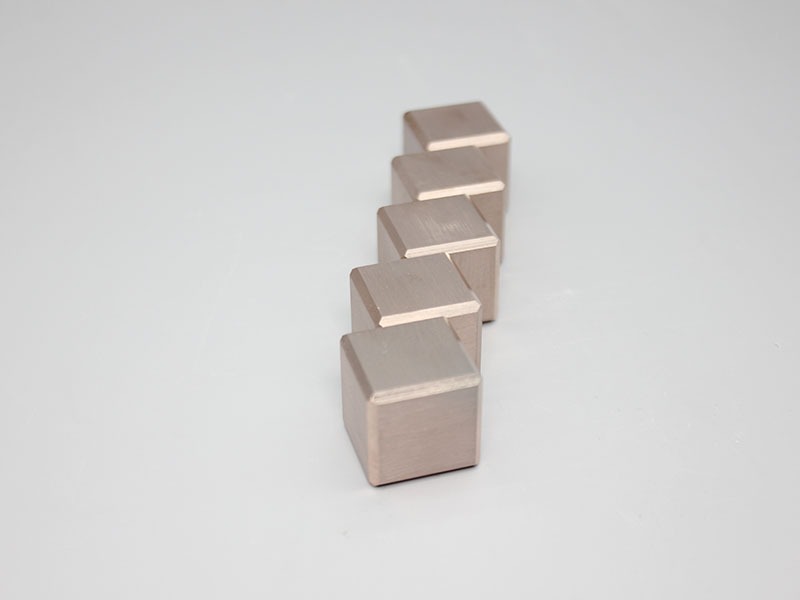

pure tungsten price manufacturer is a company that primarily deals with the research and manufacture of tungsten-based materials, which are heavy yet still possess great mechanical properties. The engineers are very aware of the demanding application areas and thus the production of counterweights, kinetic energy penetrators, and shielding components are just a few to name. All this is achieved through continuous research and upgraded processing technology, which by the way keeps the standards of global engineering markets for their products as they have uniform density, superior hardness, and high resistance to wear.

Q: Why is Tungsten heavy alloy used in precision instruments? A: Its dimensional stability and mass make it perfect for counterweights and vibration control in sensitive devices. Q: How does Tungsten heavy alloy enhance radiation safety? A: It blocks radiation efficiently without increasing volume, protecting both users and surrounding equipment. Q: Can Tungsten heavy alloy be shaped into complex geometries? A: Yes, it can be formed into intricate designs using powder metallurgy and advanced machining techniques. Q: What environmental conditions can Tungsten heavy alloy withstand? A: It performs reliably under high pressure, moisture, and chemical exposure without corrosion or deformation. Q: How is Tungsten heavy alloy contributing to modern engineering? A: It supports high-performance manufacturing, offering strength, precision, and sustainability across industries.

What I love about the tungsten jig is how fast it sinks and how naturally it moves in the water.

I appreciate that Tungsten heavy alloy is non-toxic yet just as heavy and stable as lead — a smart upgrade.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

Could you provide info about your heavy-duty tungsten jig types suitable for deep-sea fishing? Looki...

We are looking for high-density tungsten jig for our upcoming fishing gear line. Could you please se...

Copyright © Zhuzhou Jiuding Metal Technology Co., Ltd. All Rights Reserved