radiation shielding tungsten heavy alloys gives the advantage of being extremely hard and at the same time readily machinable, thus providing excellent resistance to both wear and impact. It finds application in military, aerospace, and medical industries for parts which are exposed to the forces of vibration, radiation, and so on. The material's uniform density is the reason for predictable behavior which in turn is the basis for engineers to make smaller yet stronger components that will work reliably in difficult operational conditions.

radiation shielding tungsten heavy alloys is widely utilized in aerospace propulsion systems due to its thermal stress resistance and dimensional stability. It is well-suited for turbine blades, rocket nozzles, and control actuators. The alloy provides consistent mechanical reliability at extreme temperatures, allowing safe and efficient operations during long-duration missions.

As sustainability becomes a priority, the future of radiation shielding tungsten heavy alloys will be related to effective recycling and cleaner production methods. Researchers are focused on identifying ways to recover tungsten from industrial waste while maintaining alloy integrity. In addition, alloy will factor into the design of lightweight energy systems and smart infrastructure requiring mass and strength.

To extend the life cycle of radiation shielding tungsten heavy alloys, do not apply excessive force to avoid impact damage which can produce micro-cracks in the ground surface. Periodic polishing, particularly in the application of precision tools for surgery or sub-disciplines in medicine, can restore surface smoothness. Avoid contact and handling with reactive metals to minimize galvanic corrosion.

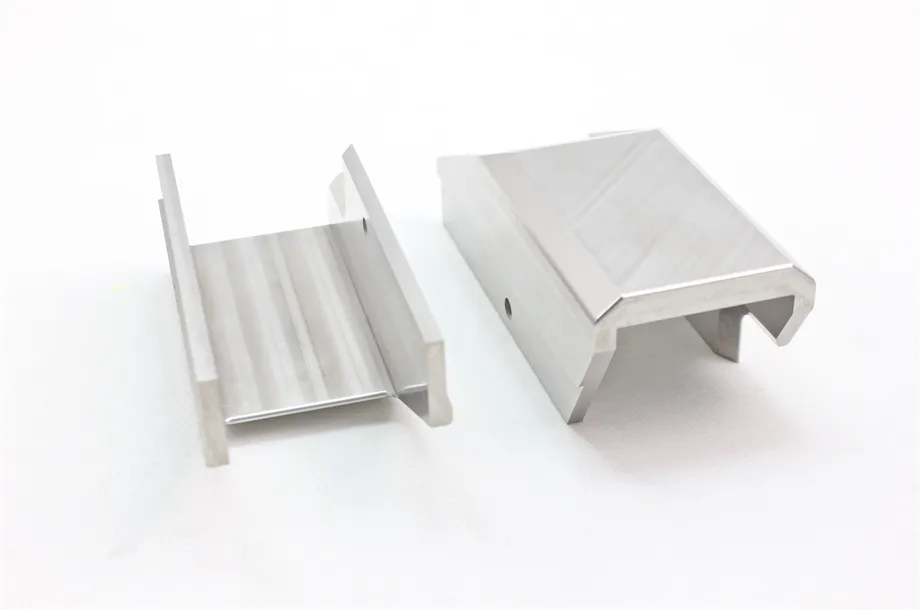

radiation shielding tungsten heavy alloys is suitable for applications that require surface area weight and mechanical strength. The material maintains an excellent wear resistance and has a high thermal stability characteristic. It is commonly found in parts for aerospace balancing, in mold making, and in heavy engineering equipment. Because of its density, radiation shielding tungsten heavy alloys provides the highest reliability and operational efficiency.

Q: How is Tungsten heavy alloy used in oil and gas exploration? A: It serves as a key material for counterweights, drilling tools, and downhole equipment due to its density and wear resistance. Q: What maintenance practices help preserve Tungsten heavy alloy components? A: Regular cleaning, controlled storage, and protection from moisture help prevent oxidation and extend service life. Q: Why does Tungsten heavy alloy perform well in vibration control? A: Its density and internal damping capacity reduce oscillations in precision machinery and aerospace systems. Q: What machining techniques are best for Tungsten heavy alloy? A: CNC milling, grinding, and electrical discharge machining are commonly used for shaping Tungsten heavy alloy with precision. Q: How does Tungsten heavy alloy support environmental sustainability? A: It replaces toxic lead in many applications while offering durability and recyclability for eco-friendly production cycles.

The tungsten jig performs great in both saltwater and freshwater; it doesn’t rust or wear out easily.

The Tungsten heavy alloy has impressive density and strength — it’s perfect for high-performance machinery.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

We are a machining parts supplier seeking tungsten heavy alloy rods for precision components. Kindly...

We are interested in tungsten heavy alloy cylinders for kinetic energy applications. Could you send ...

Copyright © Zhuzhou Jiuding Metal Technology Co., Ltd. All Rights Reserved