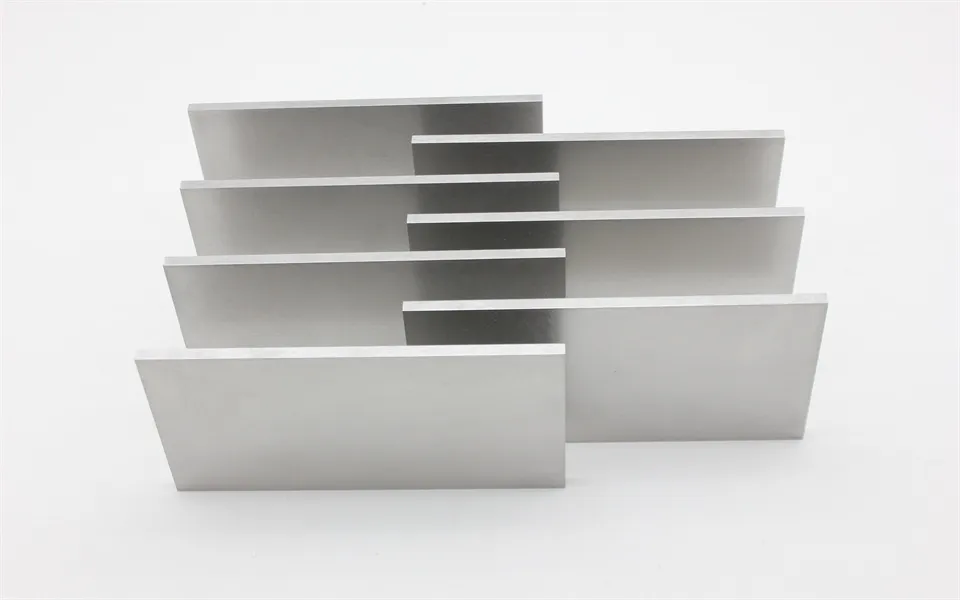

The oil and gas industry relies on tungsten alloy plate for critical components used in exploration and drilling operations. tungsten alloy plate’s density and resistance to extreme temperatures make it an ideal material for downhole tools, logging equipment, and counterweights. Its ability to withstand corrosive environments ensures consistent performance over time, reducing maintenance costs. tungsten alloy plate also provides stability in high-pressure conditions, enabling more accurate data collection and efficient resource extraction. This makes it a cornerstone material for the energy sector.

The tungsten alloy plate is also used in marine technology for sonar, submarines, and underwater robots. Its density allows for compact ballast and counterweight designs with ideal buoyancy control. Corrosion resistant to seawater, tungsten alloy plate does not lose performance after prolonged exposure. Stable and robust, tungsten alloy plate is a handy alloy for navigation and balancing equipment in deep-sea operations that require precision, endurance, and mechanical strength.

Miniaturization trends in electronics will drive further innovation in tungsten alloy plate. High density and thermal stability serve it well in terms of suitability for heat sinks and EMI shields at small scale. With decreasing device sizes and higher speeds, the need for established materials like tungsten alloy plate will grow to achieve effective power control and long-term reliability in dense electronic assemblies.

The tungsten alloy plate should be stored in a dry, moisture-free environment to prevent oxidation. Surfaces should be periodically inspected for micro-cracks. A thin coating of corrosion inhibitor will extend life. If utilized in radiation or high-heat applications, offer regular calibration checks to maintain shielding and thermal efficiency.

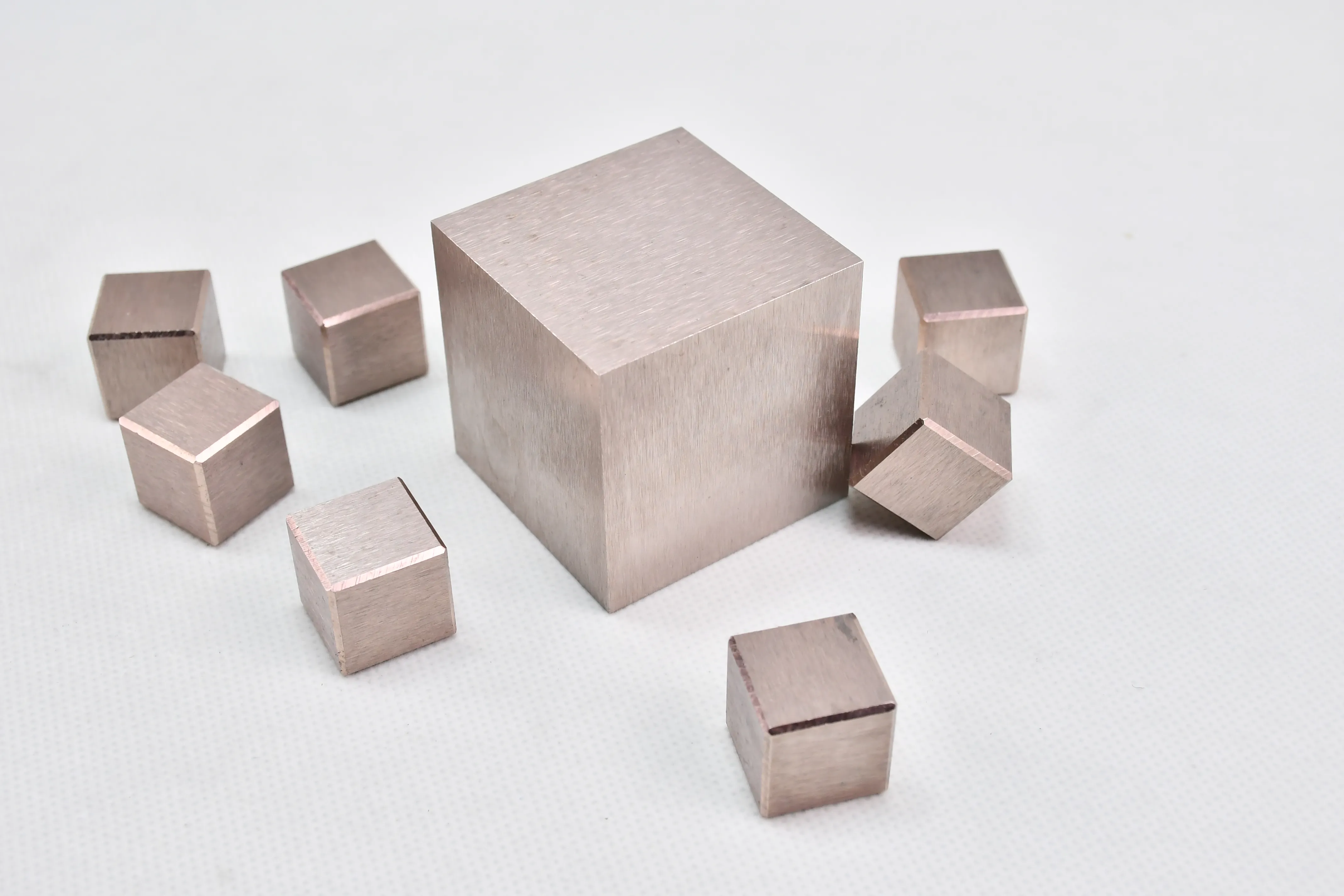

tungsten alloy plate is a critical material in the development of advanced ballistic solutions. Its high density and hardness make it an ideal choice for armor-piercing projectiles and counterweights in military applications. tungsten alloy plate’s ability to retain its properties under extreme conditions ensures superior performance in ballistic testing and real-world scenarios. Moreover, its non-toxic nature makes it a safer alternative to traditional materials like depleted uranium. For defense industries seeking reliable and eco-friendly materials, tungsten alloy plate offers unparalleled benefits.

Q: How do you ensure the quality of tungsten alloy products? A: We follow strict quality control measures, including raw material testing, production monitoring, and final inspections. Certifications such as ISO 9001 ensure that our tungsten alloy products meet global standards. Q: Is tungsten alloy suitable for marine applications? A: Yes, tungsten alloy’s corrosion resistance and high density make it ideal for marine applications, including ship ballast, underwater equipment, and offshore drilling tools. Q: What packaging options are available for tungsten alloy products? A: Our tungsten alloy products are carefully packaged to ensure safe transport. We offer standard and customized packaging solutions based on client requirements, ensuring product integrity during shipping. Q: How long does it take to produce a customized tungsten alloy product? A: Production timelines depend on the complexity and quantity of the order. Generally, customized tungsten alloy products can be completed within 2–4 weeks, with expedited options available for urgent needs. Q: Are your tungsten alloy products compliant with international standards? A: Yes, our tungsten alloy products comply with international standards such as ASTM and ISO. We ensure that all materials and processes meet global regulatory and performance requirements.

I’ve worked with Tungsten heavy alloy materials for years, and they never disappoint in precision or reliability.

The craftsmanship of the tungsten jig is excellent — it reacts quickly to every move of the rod.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

Could you provide info about your heavy-duty tungsten jig types suitable for deep-sea fishing? Looki...

Do you provide OEM service for tungsten jig? We’d like to customize colors and hook types for our ...

Copyright © Zhuzhou Jiuding Metal Technology Co., Ltd. All Rights Reserved