tungsten based alloys manufacturer provide tungsten heavy alloys with superb characteristics in terms of uniformity and structural balancing. The materials undergo processing through advanced techniques which guarantee mechanical reliability when put under stress. The engineers of the company ensure the best microstructure and bonding strength so that their alloys can withstand consistent performance during vibration, temperature change, and mechanical pressure. tungsten based alloys manufacturer present personalized production for specific uses.

tungsten based alloys manufacturer are the main source of tungsten heavy alloys which are largely applied in manufacturing medical imaging equipment and building radiation protection structures. The weightiness of the alloys provides a way to block the radiations efficiently and thus, they are considered for X-ray and CT scanner shielding. tungsten based alloys manufacturer are still making changes in their alloy composition to improve strength and machinability for special applications.

{Keywords} future will be dictated by following the trends such as sustainability and circular economy. On the one hand, recycling programs and raw material recovery processes will lower production costs and the overall impact of the factory on the environment. On the other hand, the use of recycling techniques in the metallurgical processes will only be using the best performance alloys, this enabling tungsten based alloys manufacturer to be green metal manufacturers in the high-density metals sector.

The long-term care of tungsten heavy alloys provided by tungsten based alloys manufacturer consists in maintaining a clean, controlled environment and preventing harsh agents' exposure. When components operate in high vibration or thermal environments, periodic alignment and inspection become mandatory. Proper cleaning, lubrication, and protective handling will be the factors that will determine strength, precision, and service longevity.

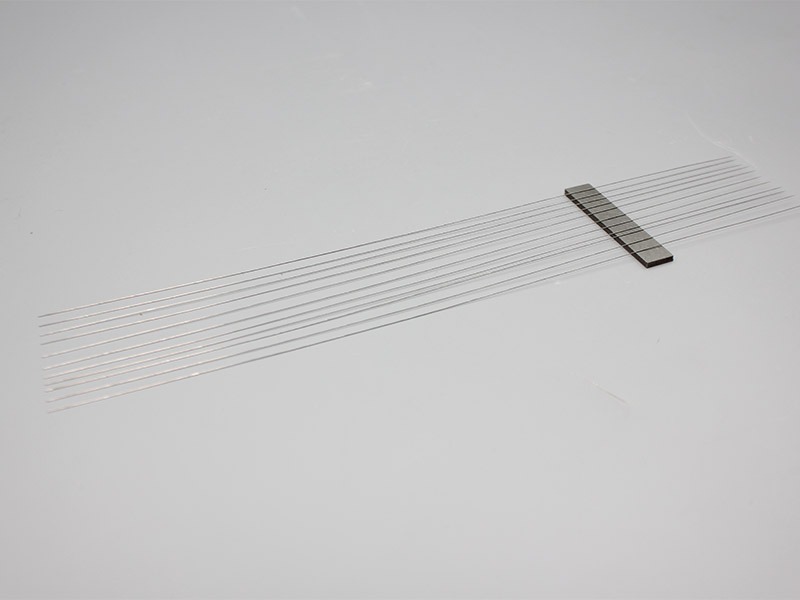

tungsten based alloys manufacturer are producing tungsten heavy alloys with the desirable properties such as perfect strength-to-weight ratio and trustworthy operation in extreme conditions. The materials are subjected to powder metallurgy and vacuum sintering techniques in a very careful manner. A stringent control is applied for density uniformity and surface finish on each product. The tungsten based alloys manufacturer’s got to invention leads to the establishment of high-grade tungsten alloys for intricate industrial applications all over the globe.

Q: Why is Tungsten heavy alloy used in precision instruments? A: Its dimensional stability and mass make it perfect for counterweights and vibration control in sensitive devices. Q: How does Tungsten heavy alloy enhance radiation safety? A: It blocks radiation efficiently without increasing volume, protecting both users and surrounding equipment. Q: Can Tungsten heavy alloy be shaped into complex geometries? A: Yes, it can be formed into intricate designs using powder metallurgy and advanced machining techniques. Q: What environmental conditions can Tungsten heavy alloy withstand? A: It performs reliably under high pressure, moisture, and chemical exposure without corrosion or deformation. Q: How is Tungsten heavy alloy contributing to modern engineering? A: It supports high-performance manufacturing, offering strength, precision, and sustainability across industries.

I’ve used the tungsten jig for months, and its weight balance makes it super easy to control even in deep spots.

I’ve worked with Tungsten heavy alloy materials for years, and they never disappoint in precision or reliability.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

We are a machining parts supplier seeking tungsten heavy alloy rods for precision components. Kindly...

We need tungsten heavy alloy plates for counterweight applications. Please share available thickness...

Copyright © Zhuzhou Jiuding Metal Technology Co., Ltd. All Rights Reserved