tungsten grass jig manufacturer has made a name for itself as a producer of tungsten jigs without sacrificing beauty as the main component and function as the other. Every single jig enables natural-looking underwater movement and at the same time can cope with difficult fishing situations. The engineers at tungsten grass jig manufacturer rely on the most advanced methods of production to guarantee that every single jig is made according to the standards and is thus reliable for both novice and professional anglers.

The usages of tungsten grass jig manufacturer are diverse as they involve saltwater, freshwater, and coastal environments. From among the many applications, the main one is to the using of tungsten jigs by the fishermen who use them to attract fish by keeping jigs steady with varying conditions. Sensitivity is heightened due to the jigs and this leads to higher efficiency in reaching the target fish. Besides, tungsten grass jig manufacturer also provides tailor-made designs according to the fishing techniques being used, such as vertical jigging, bottom bouncing, and slow pitch, which is a mix of professional and commercial sectors.

New materials and care for the earth will be the main themes of tungsten grass jig manufacturer advancements in the next years. The producers plan on cutting tungsten scrap to the utmost minimum by means of their state-of-the-art recycling and recovering systems. Compression design software will not only make it easier to weight optimization and motion analysis but also improve the overall design of the product. tungsten grass jig manufacturer will go on creating new, colorful and trend-setting, surface finishes that resist abrasion and still look good, hence such jigs will be popular in both fresh and saltwater fishing for a long time.

Proper maintenance of tungsten grass jig manufacturer tungsten jigs means that regular cleaning and careful handling will be necessary. After fishing has finished, they must be rinsed in clean water to get rid of salt or dead animals. They should be completely dry before being put back in tackle boxes. It is advisable to keep them apart from hooks and other metal objects to avoid scratches. Light protective coating now and then is helpful to prolong the life of the product and keep it shiny like new.

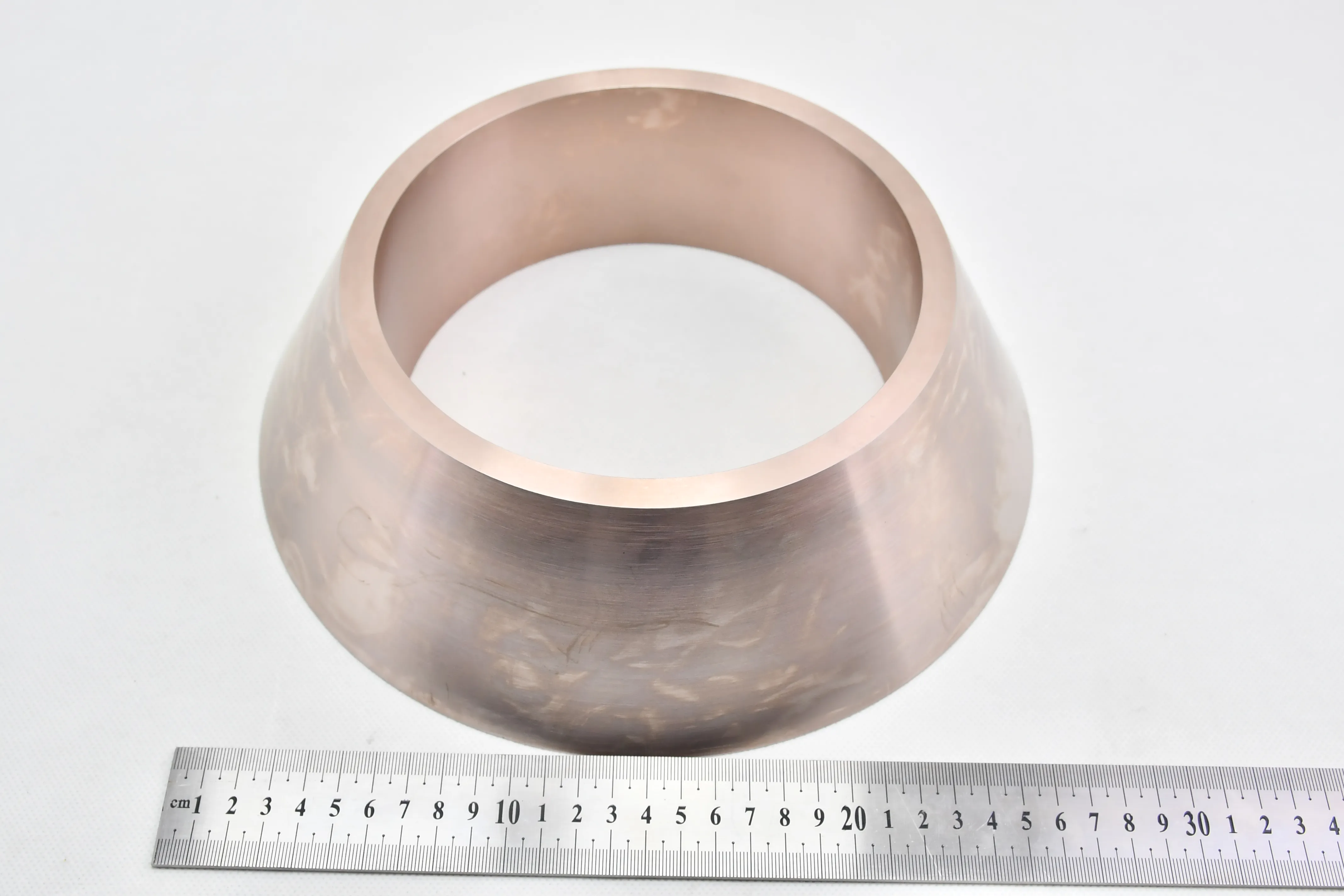

tungsten grass jig manufacturer is all about making hard-wearing and efficient tungsten jigs that not only improve the accuracy of the fishermen but also the depth performance. The manufacturers use diverse techniques that include high-pressure sintering, polishing, and more to achieve smooth finishes and uniformity in density. The jigs come with features that reduce drag, enable better movement of the fake, and accept different water conditions. tungsten grass jig manufacturer not only does sizing and coloring but also shapes the jigs according to the fish's likes, thus providing excellent saltwater and freshwater catches.

Q: What’s the best way to transport Tungsten jig? A: Use a divided tackle box to keep each jig separate and prevent hook tangling or surface damage. Q: How can I check if Tungsten jig is damaged? A: Look for cracked bodies, bent hooks, or chipped coatings during regular inspections. Q: Is Tungsten jig suitable for casting? A: Yes, its balanced weight and aerodynamic design allow accurate and long-distance casting. Q: What affects Tungsten jig performance most? A: Factors like water current, salinity, and temperature influence its action and sink rate. Q: Should I oil Tungsten jig hooks? A: Applying a light oil coat prevents rust and maintains sharpness after saltwater exposure.

I’ve used the tungsten jig for months, and its weight balance makes it super easy to control even in deep spots.

The Tungsten heavy alloy has impressive density and strength — it’s perfect for high-performance machinery.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

We are interested in tungsten heavy alloy cylinders for kinetic energy applications. Could you send ...

We need tungsten heavy alloy plates for counterweight applications. Please share available thickness...

Copyright © Zhuzhou Jiuding Metal Technology Co., Ltd. All Rights Reserved