tungsten nickel alloy manufacturer are synonymous with technological advancement and their allegiance to high-quality standards in tungsten alloy production. Their alloys have an outstandingly high compressive strength along with wear resistance. A meticulous inspection is conducted of each batch for hardness, surface finish, and internal density. tungsten nickel alloy manufacturer continue to be the go-to supplier for the aerospace and defense sectors' demanding applications by making available materials that are up to the mark.

tungsten nickel alloy manufacturer’s tungsten heavy alloys are the major factor in modern engineering, particularly if an area-saving design and high mass concentration are the requirements. They are found in ship ballast, aerospace stabilizers, and earthquake shock absorbers. With the strict control of the alloy features, tungsten nickel alloy manufacturer are confident of the performance extending to both the civilian and military fields.

The future path of tungsten nickel alloy manufacturer is going to be characterized by precision customization and eco-friendly manufacturing practices. It is anticipated that the producers will use sintering techniques that emit low toxins as well as rely on green energy for their production lines. The investigation into micro-grain alloying will eventually lead to the discovery of alloys that have superior fatigue resistance thus enabling tungsten materials to meet the challenges of operating in more difficult and complex environments.

tungsten nickel alloy manufacturer suggest non-reactive oils or lubricants as a means of protection throughout storage and transportation. Moreover, alcohol cleaning is necessary before installation in order to get rid of residues. Discolouration and crevice fatigue tests for high-temperature or radiation exposed parts are to be done periodically to assure quality and reliability over time.

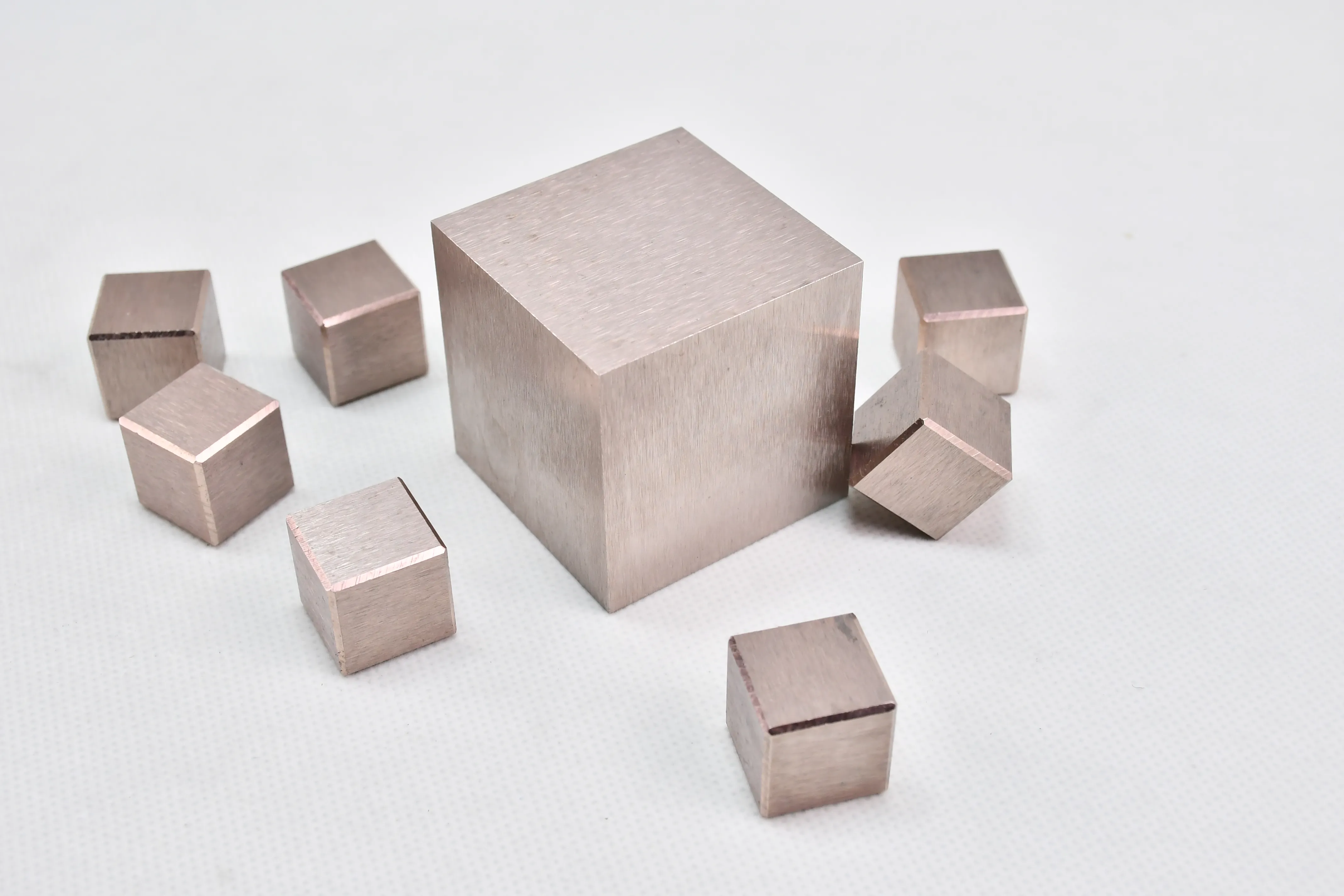

tungsten nickel alloy manufacturer have made their name in the manufacturing of tungsten heavy alloys that are outstanding in terms of density and mechanical strength. These materials can endure very high mechanical stress and even corrosive environments. The professionals at tungsten nickel alloy manufacturer apply cutting-edge machining and blending methods which allow them to have very precise control over the alloy's composition. These alloys are indispensable in the sectors of industrial, military, and medical equipment, which demand moderate mass and strength even under extreme conditions.

Q: How does Tungsten heavy alloy handle thermal expansion? A: It has a low coefficient of thermal expansion, ensuring dimensional stability under temperature fluctuations. Q: What benefits does Tungsten heavy alloy bring to electronics? A: Its thermal conductivity and durability make it suitable for heat sinks and electrical contact applications. Q: Why is Tungsten heavy alloy preferred for precision machining? A: It provides excellent dimensional accuracy and maintains balance even after extended mechanical use. Q: How can Tungsten heavy alloy components be cleaned safely? A: Use mild, non-corrosive cleaners and soft materials to remove residue without damaging the surface. Q: What industries continue to expand the use of Tungsten heavy alloy? A: Aerospace, medical, defense, and renewable energy sectors increasingly rely on it for performance-critical parts.

What I love about the tungsten jig is how fast it sinks and how naturally it moves in the water.

The Tungsten heavy alloy handles extreme pressure and heat better than most metals I’ve used.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

We operate a fishing tackle store and want to stock tungsten jig. Please send details on bulk pricin...

We are looking for high-density tungsten jig for our upcoming fishing gear line. Could you please se...

Copyright © Zhuzhou Jiuding Metal Technology Co., Ltd. All Rights Reserved