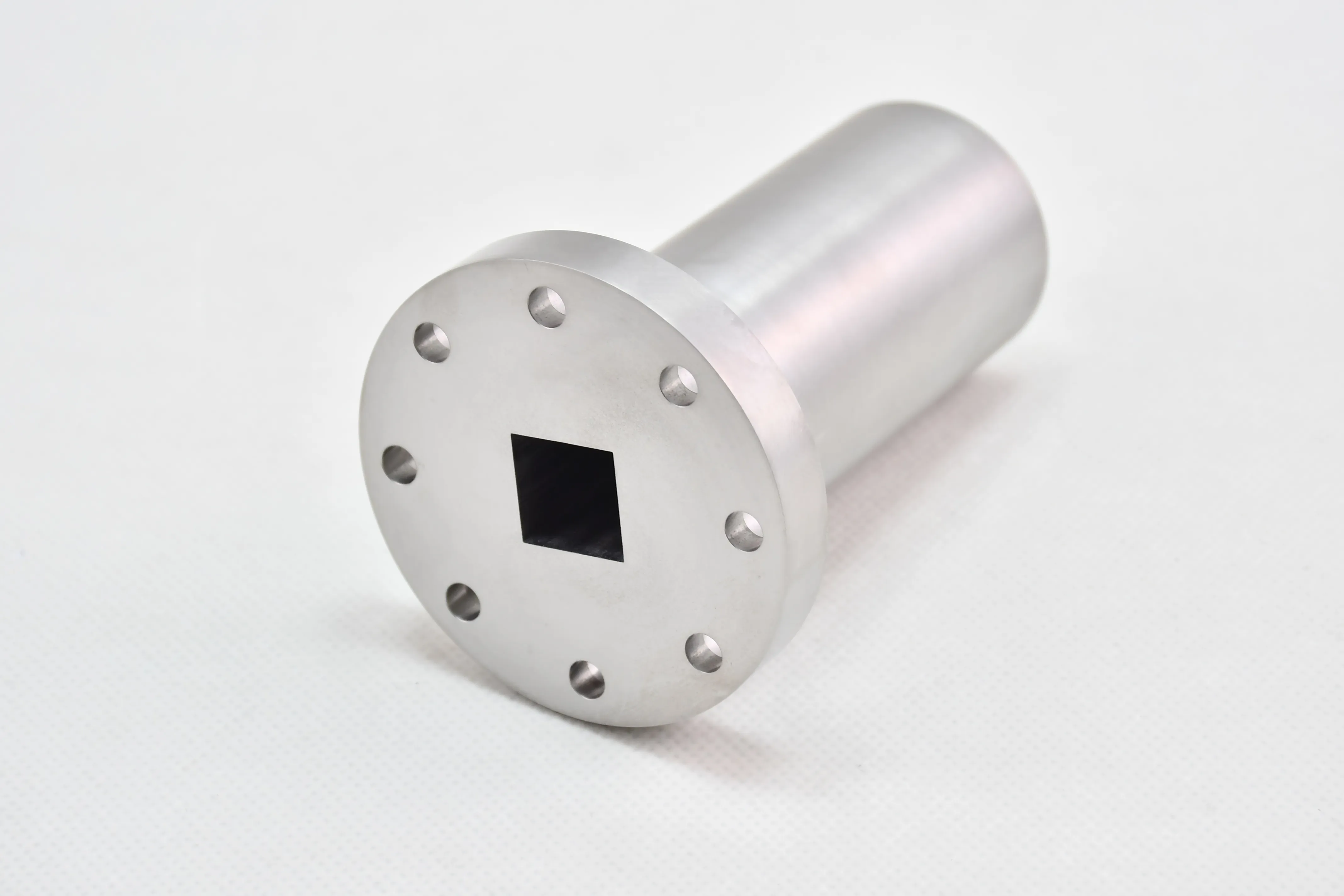

welding electrodes tungsten heavy alloys showcases a remarkable mixture of power, flexibility, and thermal fatigue resistance. It is able to endure high pressure and very high temperatures getting neither through mechanical consistency. The aforementioned properties are a reason for its usage in the aerospace industry, particularly in flight control systems, radiations, and oil drilling. Besides that, its long-term dimensional accuracy cuts down on maintenance frequency while at the same time guaranteeing the quality of output.

Within the healthcare and medical field, welding electrodes tungsten heavy alloys enjoys a wide application in shielding against radiation and as counterbalance configurations. Safety is critical in diagnosis equipment and groundbreaking technologies such as linear accelerators and gamma cameras. The aforementioned density allows for a smaller and lighter component, without sacrificing protection, which is a key driver of advanced technologies in modern healthcare applications.

In the future, welding electrodes tungsten heavy alloys will find applications that include AI-assisted design, where automated manufacturing will provide precise customization, desirable for aerospace, robotics, and medical devices. It will be a valuable component in systems that depend on especially consistent performance in severe thermal and mechanical conditions.

With proper care and maintenance, welding electrodes tungsten heavy alloys will provide reliable service long into the future. After use, components should be wiped down to remove moisture and debris from the surfaces as continuous exposure to these elements may cause surface oxidation. When the component is not in use, it should be stored in a temperature controlled, dry environment free from corrosion or mechanical fatigue.

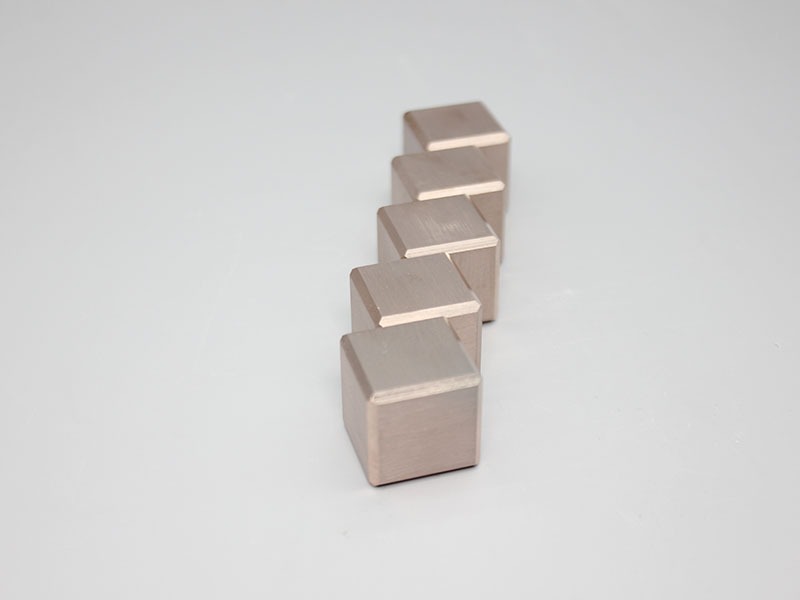

The metal's durability, welding electrodes tungsten heavy alloys, supports demanding mechanical operations in the automotive and marine industries. Its main attributes of wear resistance and strength, along with the characteristics of high-performance, ensure the lift of the main product over long-term operations.

Q: What makes Tungsten heavy alloy valuable in balancing applications? A: Its high density allows accurate weight adjustment in small volumes, ensuring perfect balance in rotating machinery. Q: Is Tungsten heavy alloy corrosion-resistant? A: Yes, it shows strong resistance to oxidation and chemical corrosion, even in harsh environments. Q: How does Tungsten heavy alloy contribute to medical safety? A: It is used to shield radiation without releasing harmful substances, ensuring operator and patient protection. Q: Why is Tungsten heavy alloy used in kinetic energy penetrators? A: Its density and hardness allow it to transfer energy effectively on impact, making it ideal for defense-grade applications. Q: Can Tungsten heavy alloy be recycled efficiently? A: Yes, it can be fully recycled through refining and powder recovery, maintaining material integrity.

I’ve used the tungsten jig for months, and its weight balance makes it super easy to control even in deep spots.

I appreciate that Tungsten heavy alloy is non-toxic yet just as heavy and stable as lead — a smart upgrade.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

I’m interested in your tungsten jig models used for saltwater fishing. Please share your catalog a...

Our aerospace division is sourcing tungsten heavy alloy counterweights. Please confirm density, tole...

Copyright © Zhuzhou Jiuding Metal Technology Co., Ltd. All Rights Reserved