Intended for engineering purposes requiring high performance, wha tungsten heavy alloys offers structural strength when there are density and weight restrictions. Its density facilitates good energy absorption and stability after repeated cycles of stress while demonstrating exceptional performance in counterweights, balancing devices, and damping devices. In addition, wha tungsten heavy alloys is resistant to corrosion and oxidation, contributing to a long service life in a wet or chemically exposed environment.

wha tungsten heavy alloys is growing in use in the automotive industry as precautions in crankshaft balancing, as a damping element, and for high-performance racing components. Its dense design allows for precise control of oscillatory rotational forces to enhance vehicle stability and overall engine efficiency. The material's durability in high-temperature and stress environments serves to maximize operational performance over the lifespan of the engine.

{Keywords} provides white space for development in future advanced space exploration applications. As expected, lighter, radiation resistant composites derived from a process involving wha tungsten heavy alloys will be needed for deep space missions. The future of wha tungsten heavy alloys in further evolving powder metallurgy and 3D forming designs and processes will encourage further innovation for advanced aerospace applications.

Good maintenance of wha tungsten heavy alloys ensures durable performance in extreme conditions. Periodically inspect mechanical joint and contact areas to detect early wear. In instances when oxidation has formed, buff the appearace with a mild abrasive pad. You can expect the oxidation to lose its unwanted appearance, but the performance of the wha tungsten heavy alloys will not be adversely affected.

wha tungsten heavy alloys exhibits remarkable strength, density, and corrosion resistance. That property is required for applications like oil drilling, as well as for medical shielding and industrial balancing systems. Performance is established, even in rigorous work environments, for structural longevity and stability.

Q: What makes Tungsten heavy alloy essential in engineering applications? A: Tungsten heavy alloy is essential because of its exceptional density, hardness, and thermal stability, making it reliable for use in high-performance mechanical and structural components. Q: How is Tungsten heavy alloy produced? A: It is made through powder metallurgy, where tungsten powder is blended with nickel, iron, or copper and sintered at high temperatures to form a compact, durable alloy. Q: Why is Tungsten heavy alloy suitable for aerospace industries? A: Its superior weight distribution and resistance to thermal stress make it perfect for use in counterbalances, rotor systems, and aircraft control components. Q: Can Tungsten heavy alloy be machined easily? A: While it is very dense and hard, it can be precisely machined using specialized tools designed for high-strength materials. Q: In which fields is Tungsten heavy alloy commonly applied? A: It is widely used in defense, medical imaging, oil drilling, aerospace, and industrial balancing systems.

The Tungsten heavy alloy provides solid consistency in production; every piece meets our exact requirements.

The craftsmanship of the tungsten jig is excellent — it reacts quickly to every move of the rod.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

We operate a fishing tackle store and want to stock tungsten jig. Please send details on bulk pricin...

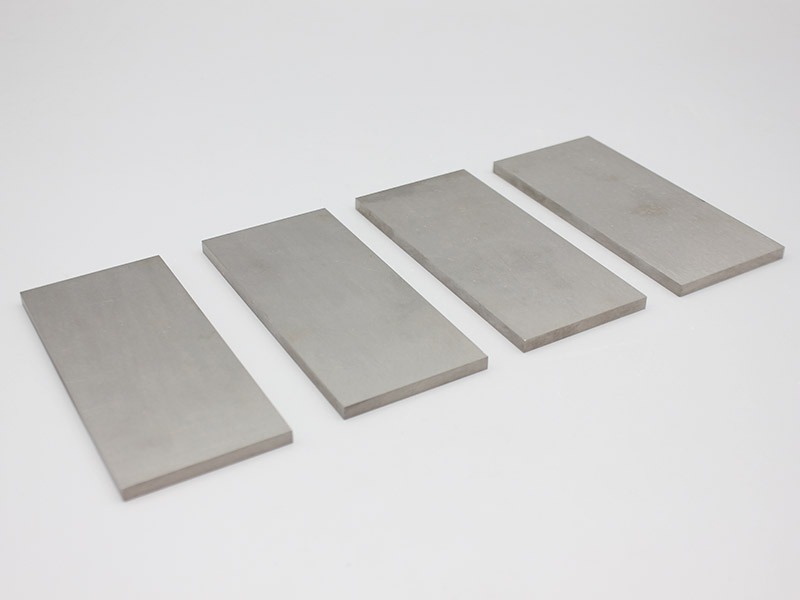

We need tungsten heavy alloy plates for counterweight applications. Please share available thickness...

Copyright © Zhuzhou Jiuding Metal Technology Co., Ltd. All Rights Reserved