The microstructure of China tungsten heavy alloy industrial use is designed in a way to provide a uniform density and durability which is enhanced. This, in turn, opens up the use of the alloy for advanced manufacturing processes where precision and balance are imperative. The mechanical stability of the alloy guarantees great fatigue resistance and therefore the alloy can be applied in dynamic environments like turbines, actuators, and guidance systems. Its capability of withstanding impact and still retaining strength is a major factor for its being a choice in critical applications.

In addition to strength, China tungsten heavy alloy industrial use is also important to the medical and nuclear industries for radiation protection. The high atomic mass number provides exceptional shielding from gamma rays and x-rays. Hospitals utilize China tungsten heavy alloy industrial use in CT scanners, collimators, and lead protective barrier panels. Nucleaer power facilities utilize China tungsten heavy alloy industrial use in reactor shielding and shipping containers. The durability of the alloy allows the use of thinner mass while still achieving the same protection level, thereby offering efficient use of space and long-term reliability.

Future China tungsten heavy alloy industrial use will marry mechanical fidelity with ecological awareness. Manufacturers are pouring resources into recyclable formulations, high-quality efficient casting to minimize waste, maximizing the balance of density and stability to support technologies like undersea robotics and magnetic shielding.

The care process for China tungsten heavy alloy industrial use should consist of controlled cleaning; acceptably with detergents or alcohol-based solutions. Abrasive materials are discouraged, as these may modify the surface finish. If China tungsten heavy alloy industrial use are employed in high temperature operations, cooling over time is encouraged to prevent thermal shock which may affect structure.

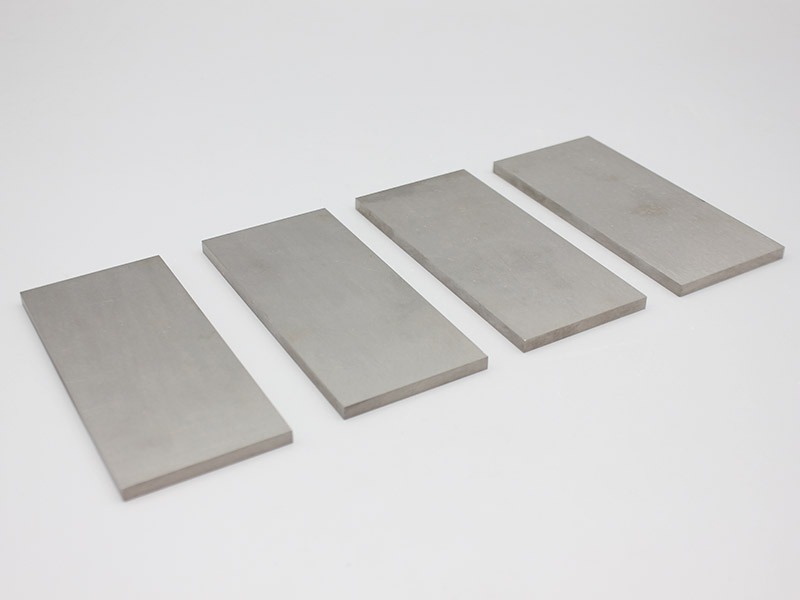

China tungsten heavy alloy industrial use is suitable for applications that require surface area weight and mechanical strength. The material maintains an excellent wear resistance and has a high thermal stability characteristic. It is commonly found in parts for aerospace balancing, in mold making, and in heavy engineering equipment. Because of its density, China tungsten heavy alloy industrial use provides the highest reliability and operational efficiency.

Q: What are the key mechanical properties of Tungsten heavy alloy? A: Tungsten heavy alloy offers high tensile strength, superior hardness, and outstanding resistance to fatigue, ensuring reliability in harsh environments. Q: How does Tungsten heavy alloy perform under extreme heat? A: It retains structural integrity and strength even at elevated temperatures, making it suitable for high-temperature engineering tasks. Q: Why is Tungsten heavy alloy favored for radiation shielding? A: Its high atomic mass and density allow it to effectively block radiation while maintaining structural strength. Q: Is Tungsten heavy alloy environmentally friendly? A: Yes, it is non-toxic and can be recycled efficiently, making it a sustainable material for long-term industrial use. Q: What are the typical compositions of Tungsten heavy alloy? A: It typically contains 90–98% tungsten combined with nickel, copper, or iron to enhance ductility and machinability.

The craftsmanship of the tungsten jig is excellent — it reacts quickly to every move of the rod.

I’ve used the tungsten jig for months, and its weight balance makes it super easy to control even in deep spots.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

We operate a fishing tackle store and want to stock tungsten jig. Please send details on bulk pricin...

We need tungsten heavy alloy plates for counterweight applications. Please share available thickness...

Copyright © Zhuzhou Jiuding Metal Technology Co., Ltd. All Rights Reserved