With the change in industrial technologies, China tungsten heavy alloy exporters is still the material of choice for those parts that need both bulk and strength. Its high melting point and low plasticity make it an able performer during stress that is extreme and yet it remains precise in its dimensions. This is why engineers use it for making vibration absorbers, aircraft components, and kinetic energy penetrators. The coexistence of hardness and ductility guarantees a long operational lifetime, thus, making China tungsten heavy alloy exporters a necessary input in high-performance engineering applications.

Vibration-damping applications implement China tungsten heavy alloy exporters in high-precision and high-value manufacturing. Manufacturing machinery, engaged for semiconductor or optics applications, utilize the alloy in base mounts and balancing plates. The weight of the material mitigates anti-resonance and enforces accuracy in very delicate product manufacturing where stability is critical.

{Keywords} provides white space for development in future advanced space exploration applications. As expected, lighter, radiation resistant composites derived from a process involving China tungsten heavy alloy exporters will be needed for deep space missions. The future of China tungsten heavy alloy exporters in further evolving powder metallurgy and 3D forming designs and processes will encourage further innovation for advanced aerospace applications.

For machinery equipped with China tungsten heavy alloy exporters components, it is ideal to have a scheduled time to perform maintenance of the machinery. As part of planned maintenance, check the components for alignment and correct lubrication. When dust or residue is present, clean the surfaces regularly to adequately avoid abrasive wear. The parts must remain cool and dry for the alloy to properly maintain mechanical strength and to resist mechanical fatigue.

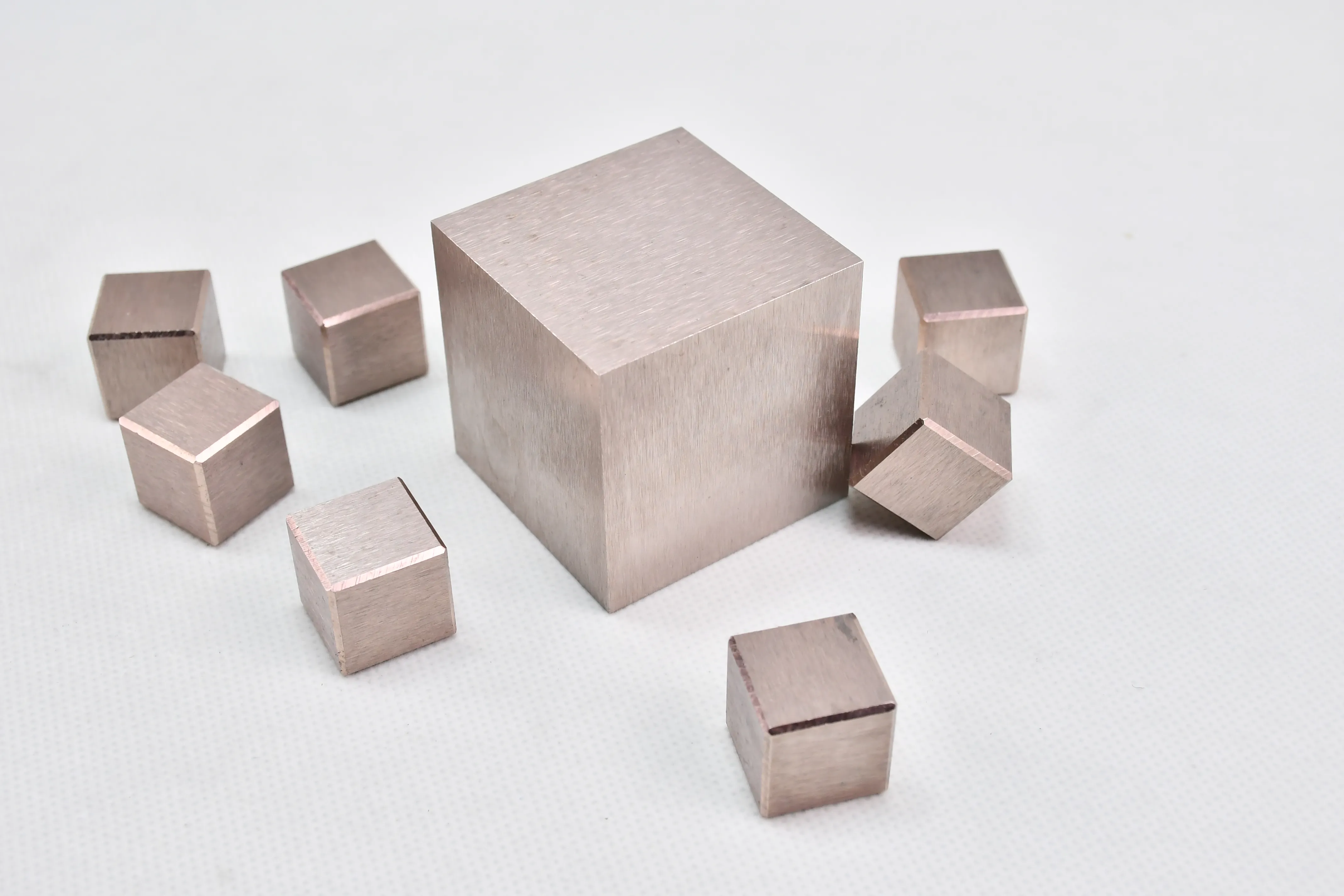

China tungsten heavy alloy exporters exhibits remarkable strength, density, and corrosion resistance. That property is required for applications like oil drilling, as well as for medical shielding and industrial balancing systems. Performance is established, even in rigorous work environments, for structural longevity and stability.

Q: What are the key mechanical properties of Tungsten heavy alloy? A: Tungsten heavy alloy offers high tensile strength, superior hardness, and outstanding resistance to fatigue, ensuring reliability in harsh environments. Q: How does Tungsten heavy alloy perform under extreme heat? A: It retains structural integrity and strength even at elevated temperatures, making it suitable for high-temperature engineering tasks. Q: Why is Tungsten heavy alloy favored for radiation shielding? A: Its high atomic mass and density allow it to effectively block radiation while maintaining structural strength. Q: Is Tungsten heavy alloy environmentally friendly? A: Yes, it is non-toxic and can be recycled efficiently, making it a sustainable material for long-term industrial use. Q: What are the typical compositions of Tungsten heavy alloy? A: It typically contains 90–98% tungsten combined with nickel, copper, or iron to enhance ductility and machinability.

The tungsten jig feels incredibly durable — I’ve caught dozens of fish, and it still looks new.

I appreciate that Tungsten heavy alloy is non-toxic yet just as heavy and stable as lead — a smart upgrade.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

Do you provide OEM service for tungsten jig? We’d like to customize colors and hook types for our ...

We are interested in tungsten heavy alloy cylinders for kinetic energy applications. Could you send ...

Copyright © Zhuzhou Jiuding Metal Technology Co., Ltd. All Rights Reserved