painting tungsten jig heads manufacturer is a different brand for a reason as it produces jigs made of tungsten that are very small in size but high in density and precision-engineering. The whole process of manufacturing ensures that the jigs are accurately balanced, resistant to corrosion, and have more underwater movement. In addition, the quality of every jig is tested thoroughly to be very good for use in both salt and fresh water. The professionals' attention to detail pays off for painting tungsten jig heads manufacturer, allowing them to offer the most reliable and stable performance, thereby, the best fishing experience with all the strength and reliability professional anglers expect.

painting tungsten jig heads manufacturer tungsten jigs are a common choice in deep-sea fishing, allowing the fishermen to arrive at their targeted places quicker with less energy used. Their density is a factor in helping with the weight but lure size is not of any concern. These jigs are a usual tool in both sport fishing and also the commercial fishing fleets. The technological innovations from painting tungsten jig heads manufacturer make the jigs very fast in going through different underwater terrains while still keeping up with the bait motion.

The painting tungsten jig heads manufacturer development trend is towards higher efficiency and less impact on the environment. Energy-efficient furnaces and digital monitoring systems will be installed in future factories to not only save energy but also to enhance production accuracy. More jig varieties to suit different fishing techniques will be made available. painting tungsten jig heads manufacturer also intends to work with material scientists to develop new tungsten composites for professional use that are lighter and just as strong as the current ones.

Using painting tungsten jig heads manufacturer products with care guarantees their long-lasting existence and reliability in performance. Every time after indicated use, the tungsten jigs have to be washed with clean water to get rid of salt, sand, and dirt. It is advisable to completely dry them up before putting them away to keep the metal parts from rusting. Don't store them in wet or tight places. Upsurge checks of any wear and tear on the surface, hooks being loose, or coating being damaged, and use of either protective oil or silicone spray for the purpose of maintaining smooth performance should be a routine.

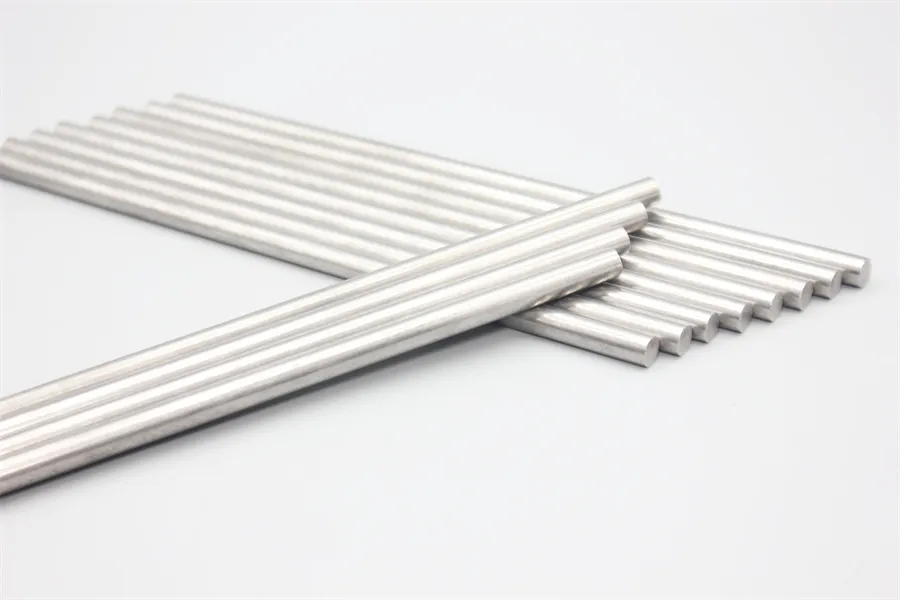

painting tungsten jig heads manufacturer is all about making hard-wearing and efficient tungsten jigs that not only improve the accuracy of the fishermen but also the depth performance. The manufacturers use diverse techniques that include high-pressure sintering, polishing, and more to achieve smooth finishes and uniformity in density. The jigs come with features that reduce drag, enable better movement of the fake, and accept different water conditions. painting tungsten jig heads manufacturer not only does sizing and coloring but also shapes the jigs according to the fish's likes, thus providing excellent saltwater and freshwater catches.

Q: What is the main advantage of using Tungsten jig in modern fishing? A: Tungsten jig offers superior density, allowing faster sinking and enhanced sensitivity for detecting even the slightest bite underwater. Q: How can I clean Tungsten jig after a fishing trip? A: Rinse it thoroughly with fresh water, wipe it dry with a soft cloth, and let it air-dry completely before storage. Q: Is Tungsten jig resistant to corrosion? A: Yes, Tungsten jig is naturally corrosion-resistant, but regular cleaning after saltwater use is still recommended to preserve coating and hook sharpness. Q: Can Tungsten jig be used effectively in muddy or murky water? A: Yes, its compact design allows it to maintain balance and visibility, especially when paired with bright or reflective finishes. Q: What maintenance tips help keep Tungsten jig in top condition? A: Avoid prolonged exposure to moisture, check hooks for sharpness, and store each jig separately to prevent paint damage or tangling.

The craftsmanship of the tungsten jig is excellent — it reacts quickly to every move of the rod.

The Tungsten heavy alloy provides solid consistency in production; every piece meets our exact requirements.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

Our aerospace division is sourcing tungsten heavy alloy counterweights. Please confirm density, tole...

Could you provide your latest price list and production capacity for tungsten heavy alloy bars? We p...

Copyright © Zhuzhou Jiuding Metal Technology Co., Ltd. All Rights Reserved