One of the greatest advantages of tungsten alloy is its adaptability to specific application requirements. Its machinability allows manufacturers to create intricate components with precise dimensions. Whether it’s for medical devices, industrial machinery, or aerospace equipment, tungsten alloy can be tailored to meet unique performance needs. Advanced manufacturing technologies further enhance its versatility, enabling complex designs and innovative solutions. For companies seeking customized materials that deliver consistent results, tungsten alloy is a clear winner.

The tungsten alloy is a key material for the defense market, used in kinetic energy penetrators, armor plate, and radiation shielding. Its high density provides deep penetration capability and resistance to impact. Unlike traditional materials, tungsten alloy retains mechanical integrity under extreme heat and stress. It offers high reliability in ballistic components, projectiles, and aircraft counterweights, improving both safety and performance in extreme defense applications worldwide.

Sustainability will drive recycling innovation in the tungsten alloy sector. Emerging recovery technologies will facilitate efficient extraction of nickel and tungsten from scrap with little energy loss. Green production and closed-loop processing will render tungsten alloy a cornerstone of sustainable heavy-metal production in the future.

In cleaning tungsten alloy tools, non-abrasive cleaning materials should be used. Abrasive chemicals can harm the surface finish or result in pitting. Lubrication of joints and threaded parts on a regular basis minimizes friction and wear. Periodical dimensional inspection ensures mechanical stability and accurate operation under severe conditions.

The medical industry leverages the unique properties of tungsten alloy for various critical applications. tungsten alloy’s high density and radiation shielding capabilities make it ideal for medical imaging devices, such as X-ray and CT scanners. It is also used in radiotherapy equipment to protect patients and medical personnel from harmful radiation. Additionally, tungsten alloy is employed in surgical instruments, offering strength and precision for delicate procedures. The material’s biocompatibility further ensures safety when used in medical environments. tungsten alloy is undoubtedly a cornerstone material for advancing healthcare technology.

Q: How do you ensure the quality of tungsten alloy products? A: We follow strict quality control measures, including raw material testing, production monitoring, and final inspections. Certifications such as ISO 9001 ensure that our tungsten alloy products meet global standards. Q: Is tungsten alloy suitable for marine applications? A: Yes, tungsten alloy’s corrosion resistance and high density make it ideal for marine applications, including ship ballast, underwater equipment, and offshore drilling tools. Q: What packaging options are available for tungsten alloy products? A: Our tungsten alloy products are carefully packaged to ensure safe transport. We offer standard and customized packaging solutions based on client requirements, ensuring product integrity during shipping. Q: How long does it take to produce a customized tungsten alloy product? A: Production timelines depend on the complexity and quantity of the order. Generally, customized tungsten alloy products can be completed within 2–4 weeks, with expedited options available for urgent needs. Q: Are your tungsten alloy products compliant with international standards? A: Yes, our tungsten alloy products comply with international standards such as ASTM and ISO. We ensure that all materials and processes meet global regulatory and performance requirements.

The Tungsten heavy alloy handles extreme pressure and heat better than most metals I’ve used.

I appreciate that Tungsten heavy alloy is non-toxic yet just as heavy and stable as lead — a smart upgrade.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

Do you provide OEM service for tungsten jig? We’d like to customize colors and hook types for our ...

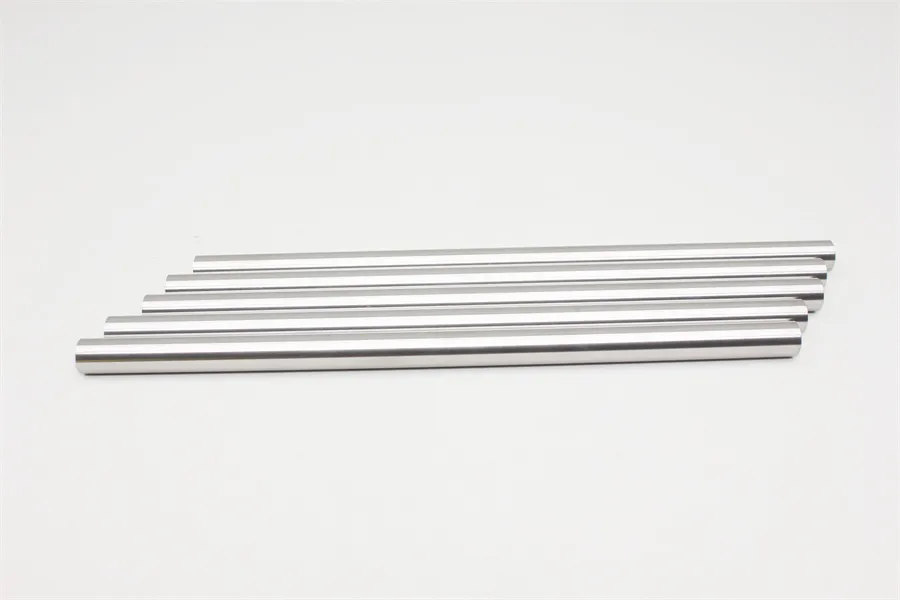

We are a machining parts supplier seeking tungsten heavy alloy rods for precision components. Kindly...

Copyright © Zhuzhou Jiuding Metal Technology Co., Ltd. All Rights Reserved