tungsten alloy data manufacturer are synonymous with technological advancement and their allegiance to high-quality standards in tungsten alloy production. Their alloys have an outstandingly high compressive strength along with wear resistance. A meticulous inspection is conducted of each batch for hardness, surface finish, and internal density. tungsten alloy data manufacturer continue to be the go-to supplier for the aerospace and defense sectors' demanding applications by making available materials that are up to the mark.

tungsten alloy data manufacturer create tungsten heavy alloys for the production of counterweights, inertial masses, and kinetic energy penetrators. The alloys can endure the extreme mechanical loads without losing their characteristics which makes them suitable for aerospace and defense applications. The accurate density control that comes with tungsten alloy data manufacturer leads to better performance of complex dynamic systems.

In the wake of global engineering striving for efficiency and sustainability, tungsten alloy data manufacturer are very likely to create cutting-edge tungsten alloys which are both high-performing and fully recyclable. The quality control supported by AI and the bonding technology will work together to eliminate inconsistency, thus making tungsten materials a solid supporter for the innovations in defense, aerospace, and renewable energy sectors.

The long-term care of tungsten heavy alloys provided by tungsten alloy data manufacturer consists in maintaining a clean, controlled environment and preventing harsh agents' exposure. When components operate in high vibration or thermal environments, periodic alignment and inspection become mandatory. Proper cleaning, lubrication, and protective handling will be the factors that will determine strength, precision, and service longevity.

tungsten alloy data manufacturer are producing tungsten heavy alloys with the desirable properties such as perfect strength-to-weight ratio and trustworthy operation in extreme conditions. The materials are subjected to powder metallurgy and vacuum sintering techniques in a very careful manner. A stringent control is applied for density uniformity and surface finish on each product. The tungsten alloy data manufacturer’s got to invention leads to the establishment of high-grade tungsten alloys for intricate industrial applications all over the globe.

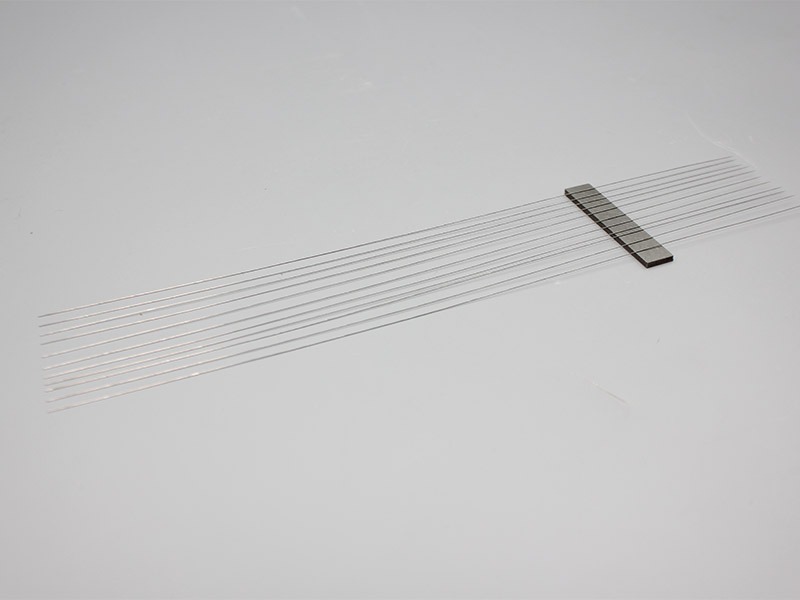

Q: Why is Tungsten heavy alloy used in precision instruments? A: Its dimensional stability and mass make it perfect for counterweights and vibration control in sensitive devices. Q: How does Tungsten heavy alloy enhance radiation safety? A: It blocks radiation efficiently without increasing volume, protecting both users and surrounding equipment. Q: Can Tungsten heavy alloy be shaped into complex geometries? A: Yes, it can be formed into intricate designs using powder metallurgy and advanced machining techniques. Q: What environmental conditions can Tungsten heavy alloy withstand? A: It performs reliably under high pressure, moisture, and chemical exposure without corrosion or deformation. Q: How is Tungsten heavy alloy contributing to modern engineering? A: It supports high-performance manufacturing, offering strength, precision, and sustainability across industries.

The craftsmanship of the tungsten jig is excellent — it reacts quickly to every move of the rod.

The Tungsten heavy alloy has impressive density and strength — it’s perfect for high-performance machinery.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

We are a machining parts supplier seeking tungsten heavy alloy rods for precision components. Kindly...

Could you provide your latest price list and production capacity for tungsten heavy alloy bars? We p...

Copyright © Zhuzhou Jiuding Metal Technology Co., Ltd. All Rights Reserved