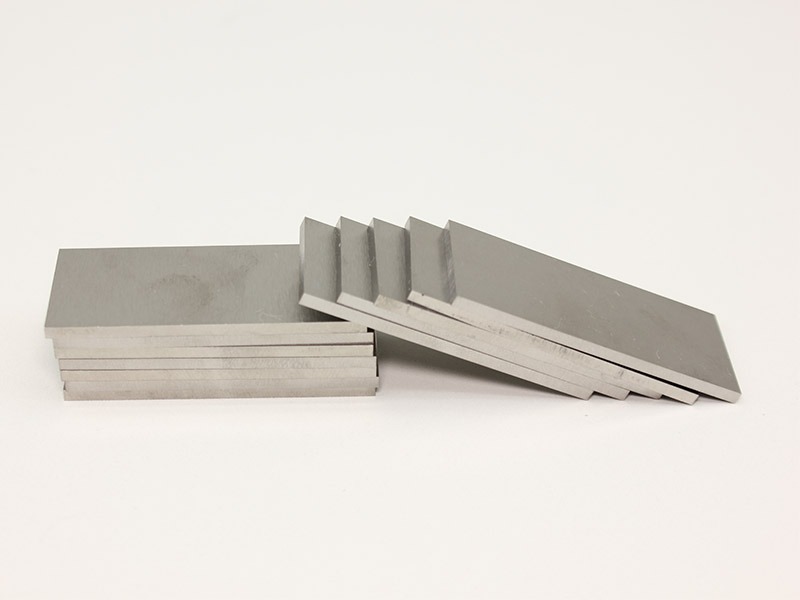

tungsten alloy manufacturer company provide tungsten heavy alloys with superb characteristics in terms of uniformity and structural balancing. The materials undergo processing through advanced techniques which guarantee mechanical reliability when put under stress. The engineers of the company ensure the best microstructure and bonding strength so that their alloys can withstand consistent performance during vibration, temperature change, and mechanical pressure. tungsten alloy manufacturer company present personalized production for specific uses.

tungsten alloy manufacturer company not only supply tungsten heavy alloys but also use them in the manufacture of medical shielding components, aerospace counterbalances, and precision molds. The product's high density provides radiation absorption and stability. tungsten alloy manufacturer company products have a role in the enhancements of radiation therapy safety, flight systems' structural stability, and industrial forming processes' accuracy.

{Keywords} future will be dictated by following the trends such as sustainability and circular economy. On the one hand, recycling programs and raw material recovery processes will lower production costs and the overall impact of the factory on the environment. On the other hand, the use of recycling techniques in the metallurgical processes will only be using the best performance alloys, this enabling tungsten alloy manufacturer company to be green metal manufacturers in the high-density metals sector.

The long-term care of tungsten heavy alloys provided by tungsten alloy manufacturer company consists in maintaining a clean, controlled environment and preventing harsh agents' exposure. When components operate in high vibration or thermal environments, periodic alignment and inspection become mandatory. Proper cleaning, lubrication, and protective handling will be the factors that will determine strength, precision, and service longevity.

tungsten alloy manufacturer company have gained recognition for their capability in the production of tungsten heavy alloys for high-performance applications. Consistency in the product is achieved through the automation of powder pressing, sintering, and testing systems in the manufacturing lines. Each tungsten alloy is characterized by excellent thermal conductivity, impact resistance, and dimensional stability. tungsten alloy manufacturer company cater to an array of industries, which are searching for reliable materials, for precision components and energy-intensive environments.

Q: What are the typical density ranges of Tungsten heavy alloy? A: It typically ranges between 17.0 and 18.8 g/cm³, providing unmatched weight and compactness for engineering designs. Q: Why is Tungsten heavy alloy used in high-impact tools? A: Its toughness and ability to resist cracking make it perfect for tools that endure strong impacts or vibration. Q: How does Tungsten heavy alloy behave in corrosive settings? A: It resists most chemical reactions, maintaining its properties in acidic or humid industrial environments. Q: What finishing methods are applied to Tungsten heavy alloy? A: Polishing and coating are often used to enhance surface quality and prevent oxidation. Q: How is Tungsten heavy alloy expected to evolve in the future? A: New manufacturing methods will focus on higher efficiency, recyclability, and improved microstructure control.

The craftsmanship of the tungsten jig is excellent — it reacts quickly to every move of the rod.

I’ve worked with Tungsten heavy alloy materials for years, and they never disappoint in precision or reliability.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

Do you provide OEM service for tungsten jig? We’d like to customize colors and hook types for our ...

Could you provide info about your heavy-duty tungsten jig types suitable for deep-sea fishing? Looki...

Copyright © Zhuzhou Jiuding Metal Technology Co., Ltd. All Rights Reserved