tungsten heavy alloy penetrator is designed for applications requiring maximum strength with minimal volume. The high density ensures the alloy has great balance and vibration resistance. The alloy has the same mechanical properties at elevated pressure, which is why it can be found in ballistic applications, commercial aerospace structures, and advanced tooling. tungsten heavy alloy penetrator is resistant to cracking, corrosion, and fatigue, so it can be employed in extreme working conditions.

In addition to strength, tungsten heavy alloy penetrator is also important to the medical and nuclear industries for radiation protection. The high atomic mass number provides exceptional shielding from gamma rays and x-rays. Hospitals utilize tungsten heavy alloy penetrator in CT scanners, collimators, and lead protective barrier panels. Nucleaer power facilities utilize tungsten heavy alloy penetrator in reactor shielding and shipping containers. The durability of the alloy allows the use of thinner mass while still achieving the same protection level, thereby offering efficient use of space and long-term reliability.

Future tungsten heavy alloy penetrator will marry mechanical fidelity with ecological awareness. Manufacturers are pouring resources into recyclable formulations, high-quality efficient casting to minimize waste, maximizing the balance of density and stability to support technologies like undersea robotics and magnetic shielding.

The life of tungsten heavy alloy penetrator is consistent with care and maintenance. Do not drop or strike it against hard surfaces, as even minor impressions will impact the balance and performance of the tungsten heavy alloy penetrator. Transport and store in tightly sealed containers to protect tungsten heavy alloy penetrator from humidity and airborne contaminants.

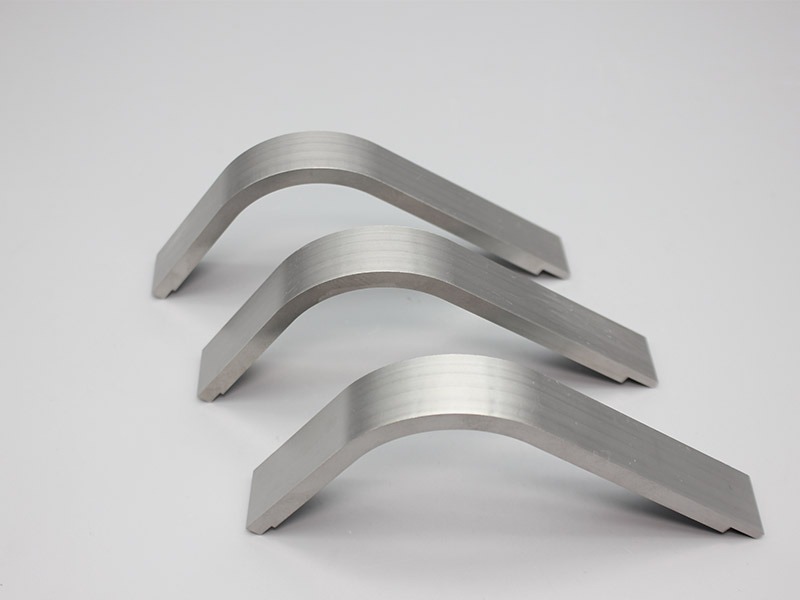

tungsten heavy alloy penetrator exhibits remarkable strength, density, and corrosion resistance. That property is required for applications like oil drilling, as well as for medical shielding and industrial balancing systems. Performance is established, even in rigorous work environments, for structural longevity and stability.

Q: What makes Tungsten heavy alloy essential in engineering applications? A: Tungsten heavy alloy is essential because of its exceptional density, hardness, and thermal stability, making it reliable for use in high-performance mechanical and structural components. Q: How is Tungsten heavy alloy produced? A: It is made through powder metallurgy, where tungsten powder is blended with nickel, iron, or copper and sintered at high temperatures to form a compact, durable alloy. Q: Why is Tungsten heavy alloy suitable for aerospace industries? A: Its superior weight distribution and resistance to thermal stress make it perfect for use in counterbalances, rotor systems, and aircraft control components. Q: Can Tungsten heavy alloy be machined easily? A: While it is very dense and hard, it can be precisely machined using specialized tools designed for high-strength materials. Q: In which fields is Tungsten heavy alloy commonly applied? A: It is widely used in defense, medical imaging, oil drilling, aerospace, and industrial balancing systems.

The tungsten jig performs great in both saltwater and freshwater; it doesn’t rust or wear out easily.

The Tungsten heavy alloy provides solid consistency in production; every piece meets our exact requirements.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

Our aerospace division is sourcing tungsten heavy alloy counterweights. Please confirm density, tole...

Do you provide OEM service for tungsten jig? We’d like to customize colors and hook types for our ...

Copyright © Zhuzhou Jiuding Metal Technology Co., Ltd. All Rights Reserved