The unique density of tungsten heavy powder and parts makes it an ideal material for counterweights in various industries. From elevators and cranes to aircraft and robotics, tungsten heavy powder and parts counterweights provide precise balance and stability. Its compact size allows engineers to design weight-efficient systems without compromising performance. Moreover, tungsten heavy powder and parts’s durability ensures long-lasting use even in demanding environments. Industries seeking optimal load distribution and reliability can greatly benefit from incorporating tungsten heavy powder and parts counterweights into their designs.

In sports and recreation equipment, tungsten heavy powder and parts improves control and accuracy. Its density enables designs to be compact in darts, golf clubs, and racing weights. Engineers and sports persons appreciate how tungsten heavy powder and parts optimizes balance and feedback without the addition of size or drag. Manufacturers rely on it to provide consistent performance, especially in competitive uses where weight distribution and stability are the secrets to winning.

As nuclear and renewable energy projects increase, tungsten heavy powder and parts will see more application in radiation shielding and thermal control systems. Its durability and absorption characteristics place it for application in future fusion reactors of the next generation. Ongoing research focuses on improving recyclability and optimizing grain structure, so that tungsten heavy powder and parts can meet future requirements of both performance and sustainability in heavy industries.

For machining or forming operations, maintain tools with tungsten heavy powder and parts in good condition by checking wear and alignment. Flush cooling systems to remove debris. Store properly between uses to prevent oxidation and dimensional warping, which ensures consistency of performance under extended industrial use.

tungsten heavy powder and parts’s radiation shielding properties make it a vital material in nuclear energy and research. Its high density effectively blocks harmful radiation, protecting workers and sensitive equipment in nuclear facilities. tungsten heavy powder and parts is used in shielding containers, reactor components, and radiation therapy devices. Its stability under high-temperature and corrosive conditions further enhances its reliability in nuclear applications. For industries requiring advanced radiation protection, tungsten heavy powder and parts is an indispensable material that ensures safety and operational efficiency.

Q: What is the minimum quantity I can order for tungsten alloy products? A: We accommodate a variety of order sizes, from small batches for prototypes to large-scale production orders. Our minimum order quantity (MOQ) depends on the product type and level of customization, ensuring flexibility for both small and large buyers. Q: How do you handle international shipping for tungsten alloy products? A: We offer secure and efficient international shipping through trusted logistics providers. Whether by air, sea, or courier, we ensure proper documentation, safe packaging, and tracking for a smooth delivery process to your location. Q: Are tungsten alloy products subject to export restrictions? A: Tungsten alloy products are generally not subject to export restrictions, but we comply with international trade regulations and provide all necessary documentation to facilitate smooth customs clearance. Buyers should verify any specific import restrictions in their country. Q: What payment methods do you accept for international buyers? A: We accept various payment methods, including wire transfers (T/T), letters of credit (L/C), and online payment options like PayPal. We are happy to work with buyers to establish a payment plan that meets their requirements. Q: Can you provide samples of tungsten alloy products before placing a large order? A: Yes, we offer samples to help buyers evaluate the quality and specifications of our tungsten alloy products. Sample costs and shipping fees can be discussed based on the specific request, and we aim to make this process easy for our clients.

The Tungsten heavy alloy handles extreme pressure and heat better than most metals I’ve used.

The tungsten jig feels incredibly durable — I’ve caught dozens of fish, and it still looks new.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

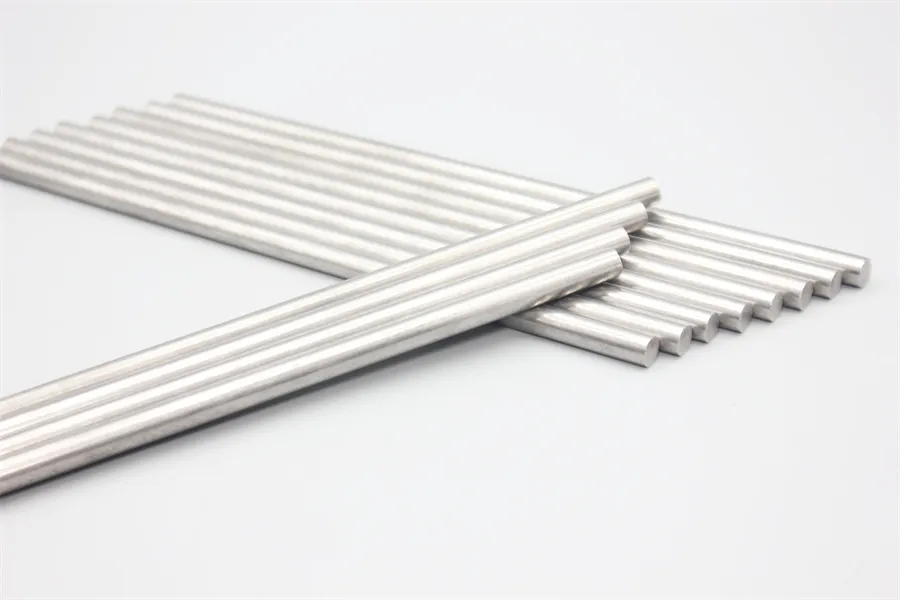

Could you provide your latest price list and production capacity for tungsten heavy alloy bars? We p...

Could you provide info about your heavy-duty tungsten jig types suitable for deep-sea fishing? Looki...

Copyright © Zhuzhou Jiuding Metal Technology Co., Ltd. All Rights Reserved