In today’s environmentally conscious world, w80cu20 offers a sustainable alternative to hazardous materials like lead. Its non-toxic nature and recyclability make it a popular choice in industries such as fishing, healthcare, and construction. w80cu20 products have a longer lifespan, reducing waste and the need for frequent replacements. Additionally, using w80cu20 helps companies meet environmental regulations while maintaining high standards of performance. Choosing w80cu20 is a step toward sustainability without compromising functionality.

The w80cu20 is widely used in oil and gas drilling, particularly for downhole drilling tools, weight bars, and stabilization collars. It possesses high density and good wear resistance, providing balance and control in drilling operations at extreme pressure. The w80cu20 performs well in corrosive or high-temperature environments, extending tool life and drilling precision to the limit. It ensures stable performance in extreme conditions where consistent stability and mechanical strength are required.

Environmental regulations are forcing industries to replace toxic substances with w80cu20. Lead-free initiatives in radiation shielding and weight systems include this alloy as increasingly prominent. Its greater density and environmental friendliness ensure long-term growth as an alternative to traditional heavy metals in a variety of global applications.

w80cu20 components maintenance records should include usage time, load cycles, and inspection results. This allows for predictive replacement before failure. Good cleaning, careful storage, and regular calibration give optimum longevity, especially in aerospace, medical, or defense systems where reliability is critical.

w80cu20 is not only known for its performance but also for its eco-friendly characteristics. Unlike lead, which poses significant environmental hazards, w80cu20 is non-toxic and recyclable. Its use in industries like fishing, where w80cu20 weights replace traditional lead, helps reduce environmental contamination. Furthermore, w80cu20’s durability ensures a longer product lifespan, reducing the need for frequent replacements. Choosing w80cu20 products contributes to sustainability efforts while meeting high-performance standards. For companies aiming to align with green initiatives, w80cu20 provides a reliable and environmentally conscious solution.

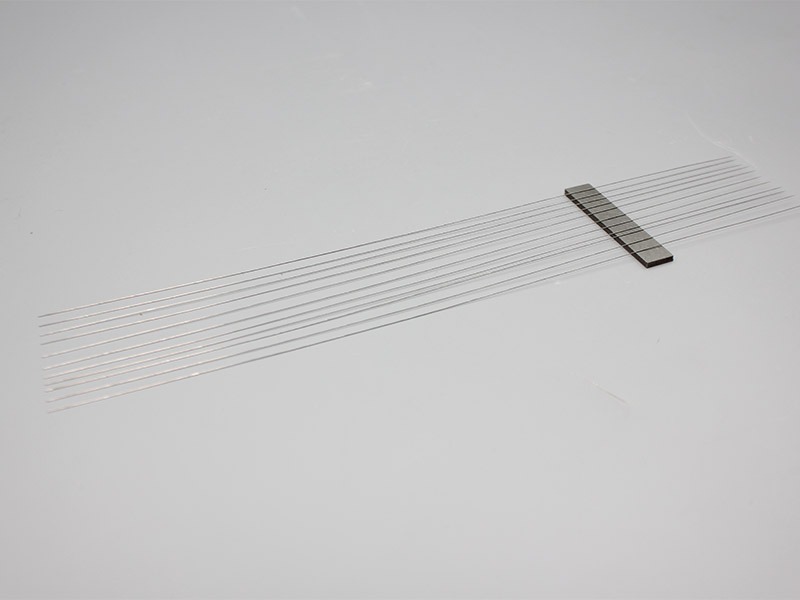

Q: What are the primary applications of tungsten alloy? A: Tungsten alloy is used in a wide range of industries, including aerospace, defense, medical, automotive, and oil and gas. Common applications include counterweights, radiation shielding, armor-piercing ammunition, and drilling components due to its exceptional density and durability. Q: Why is tungsten alloy preferred over lead for radiation shielding? A: Tungsten alloy is denser than lead and offers superior radiation absorption in a more compact form. Unlike lead, tungsten alloy is non-toxic and environmentally friendly, making it safer to handle and compliant with modern safety standards. Q: How does tungsten alloy contribute to aerospace engineering? A: In aerospace, tungsten alloy is used for balancing weights, vibration dampeners, and structural components. Its high density and strength ensure stability and performance in critical applications while maintaining compact design requirements. Q: What makes tungsten alloy a cost-effective material? A: Tungsten alloy’s durability and long lifespan reduce the need for frequent replacements, saving maintenance and operational costs over time. Its efficiency in various applications also enhances performance, providing excellent value for its initial investment. Q: Can tungsten alloy be customized for specific needs? A: Yes, tungsten alloy can be machined into precise shapes and sizes, making it highly customizable. Industries often tailor it for specific applications like medical tools, industrial parts, or aerospace components.

The Tungsten heavy alloy provides solid consistency in production; every piece meets our exact requirements.

The Tungsten heavy alloy handles extreme pressure and heat better than most metals I’ve used.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

We are interested in tungsten heavy alloy cylinders for kinetic energy applications. Could you send ...

We are a machining parts supplier seeking tungsten heavy alloy rods for precision components. Kindly...

Copyright © Zhuzhou Jiuding Metal Technology Co., Ltd. All Rights Reserved