The unique density of wnicu makes it an ideal material for counterweights in various industries. From elevators and cranes to aircraft and robotics, wnicu counterweights provide precise balance and stability. Its compact size allows engineers to design weight-efficient systems without compromising performance. Moreover, wnicu’s durability ensures long-lasting use even in demanding environments. Industries seeking optimal load distribution and reliability can greatly benefit from incorporating wnicu counterweights into their designs.

The wnicu is a critical part used in automobile manufacturing, where it finds application as balancing material for crankshafts, flywheels, and turbocharger systems. The high density in a compact size reduces vibration and stabilizes performance. wnicu is used by vehicle manufacturers to attain optimum weight distribution and fuel efficiency. The high durability of the material for extended-term operation under constant rotation makes it a critical component of modern high-performance and energy-efficient vehicle designs worldwide.

As nuclear and renewable energy projects increase, wnicu will see more application in radiation shielding and thermal control systems. Its durability and absorption characteristics place it for application in future fusion reactors of the next generation. Ongoing research focuses on improving recyclability and optimizing grain structure, so that wnicu can meet future requirements of both performance and sustainability in heavy industries.

In cleaning wnicu tools, non-abrasive cleaning materials should be used. Abrasive chemicals can harm the surface finish or result in pitting. Lubrication of joints and threaded parts on a regular basis minimizes friction and wear. Periodical dimensional inspection ensures mechanical stability and accurate operation under severe conditions.

The medical industry leverages the unique properties of wnicu for various critical applications. wnicu’s high density and radiation shielding capabilities make it ideal for medical imaging devices, such as X-ray and CT scanners. It is also used in radiotherapy equipment to protect patients and medical personnel from harmful radiation. Additionally, wnicu is employed in surgical instruments, offering strength and precision for delicate procedures. The material’s biocompatibility further ensures safety when used in medical environments. wnicu is undoubtedly a cornerstone material for advancing healthcare technology.

Q: What are the primary applications of tungsten alloy? A: Tungsten alloy is used in a wide range of industries, including aerospace, defense, medical, automotive, and oil and gas. Common applications include counterweights, radiation shielding, armor-piercing ammunition, and drilling components due to its exceptional density and durability. Q: Why is tungsten alloy preferred over lead for radiation shielding? A: Tungsten alloy is denser than lead and offers superior radiation absorption in a more compact form. Unlike lead, tungsten alloy is non-toxic and environmentally friendly, making it safer to handle and compliant with modern safety standards. Q: How does tungsten alloy contribute to aerospace engineering? A: In aerospace, tungsten alloy is used for balancing weights, vibration dampeners, and structural components. Its high density and strength ensure stability and performance in critical applications while maintaining compact design requirements. Q: What makes tungsten alloy a cost-effective material? A: Tungsten alloy’s durability and long lifespan reduce the need for frequent replacements, saving maintenance and operational costs over time. Its efficiency in various applications also enhances performance, providing excellent value for its initial investment. Q: Can tungsten alloy be customized for specific needs? A: Yes, tungsten alloy can be machined into precise shapes and sizes, making it highly customizable. Industries often tailor it for specific applications like medical tools, industrial parts, or aerospace components.

The craftsmanship of the tungsten jig is excellent — it reacts quickly to every move of the rod.

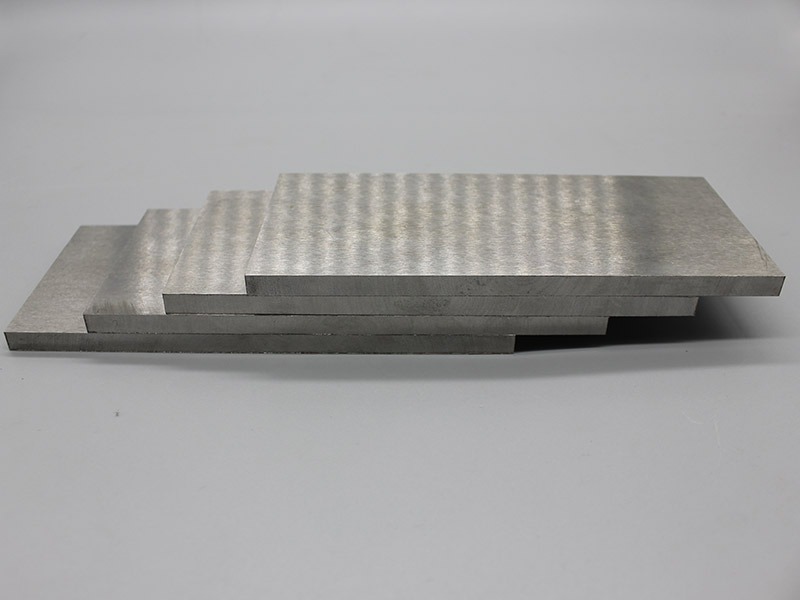

The Tungsten heavy alloy provides solid consistency in production; every piece meets our exact requirements.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

Could you provide your latest price list and production capacity for tungsten heavy alloy bars? We p...

We operate a fishing tackle store and want to stock tungsten jig. Please send details on bulk pricin...

Copyright © Zhuzhou Jiuding Metal Technology Co., Ltd. All Rights Reserved