One of the greatest advantages of tig tungsten for stainless steel is its adaptability to specific application requirements. Its machinability allows manufacturers to create intricate components with precise dimensions. Whether it’s for medical devices, industrial machinery, or aerospace equipment, tig tungsten for stainless steel can be tailored to meet unique performance needs. Advanced manufacturing technologies further enhance its versatility, enabling complex designs and innovative solutions. For companies seeking customized materials that deliver consistent results, tig tungsten for stainless steel is a clear winner.

The tig tungsten for stainless steel is a key material for the defense market, used in kinetic energy penetrators, armor plate, and radiation shielding. Its high density provides deep penetration capability and resistance to impact. Unlike traditional materials, tig tungsten for stainless steel retains mechanical integrity under extreme heat and stress. It offers high reliability in ballistic components, projectiles, and aircraft counterweights, improving both safety and performance in extreme defense applications worldwide.

Future tig tungsten for stainless steel manufacturing will involve the use of AI-aided design optimization. Predictive modeling will identify the best alloy compositions for specific industrial conditions, minimizing trial expenses and enhancing mechanical characteristics. This smart design will usher tig tungsten for stainless steel into a new generation of precision materials engineering.

In cleaning tig tungsten for stainless steel tools, non-abrasive cleaning materials should be used. Abrasive chemicals can harm the surface finish or result in pitting. Lubrication of joints and threaded parts on a regular basis minimizes friction and wear. Periodical dimensional inspection ensures mechanical stability and accurate operation under severe conditions.

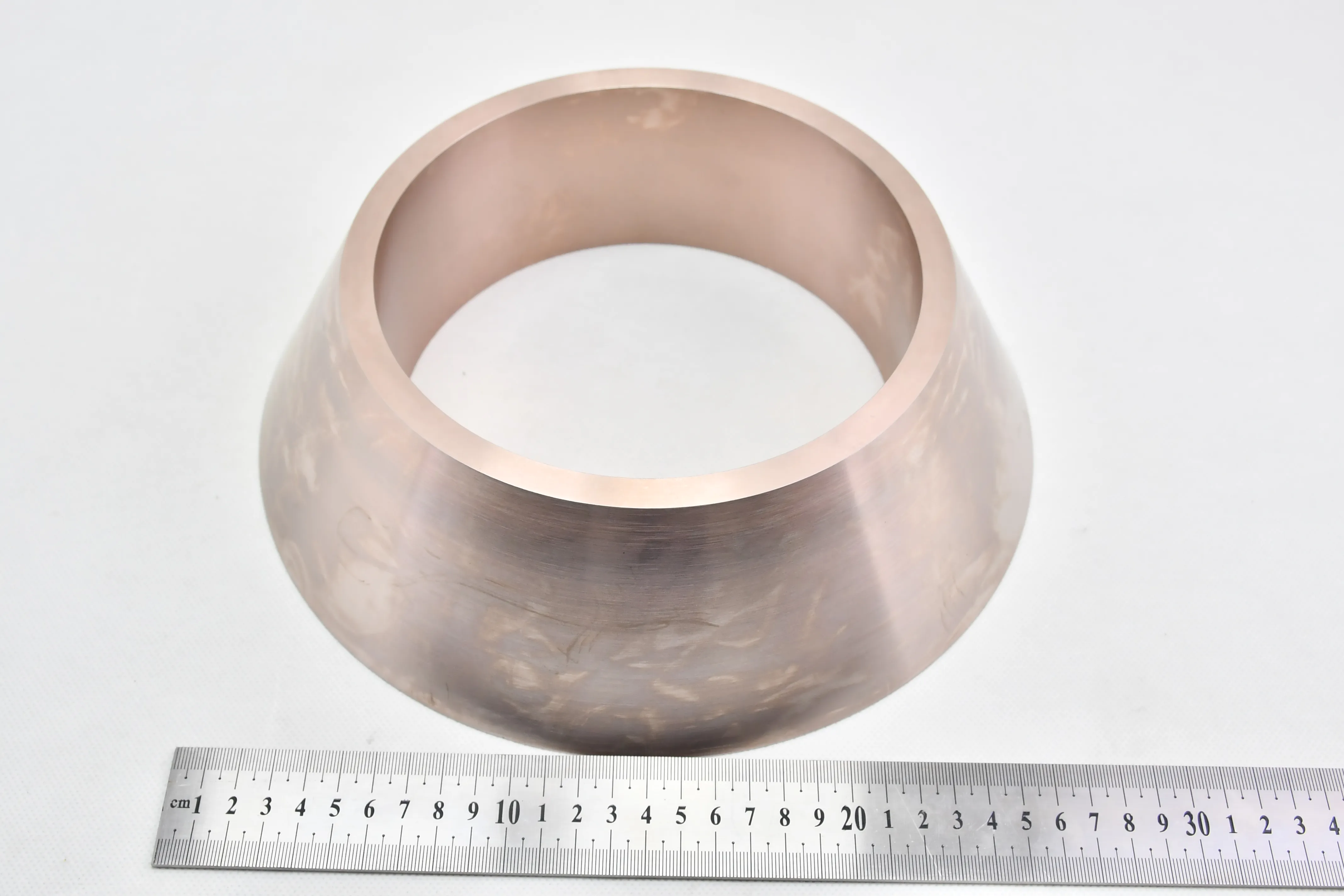

One of the standout features of tig tungsten for stainless steel is its machinability, which allows for highly customized applications. Despite its density and strength, tig tungsten for stainless steel can be precisely shaped into complex forms, meeting the specific needs of various industries. Advanced machining techniques enable the production of tig tungsten for stainless steel components with tight tolerances, ensuring compatibility with high-performance systems. From medical equipment to industrial machinery, the ability to customize tig tungsten for stainless steel enhances its versatility. Manufacturers seeking tailored solutions can rely on tig tungsten for stainless steel to deliver precision and durability.

Q: What are the environmental benefits of tungsten alloy? A: Tungsten alloy is recyclable and non-toxic, making it a sustainable choice. Its use as a replacement for lead and other hazardous materials helps industries reduce environmental impact while maintaining high performance. Q: How does tungsten alloy perform under extreme conditions? A: Tungsten alloy excels in high-temperature, high-pressure, and corrosive environments. Its superior mechanical properties ensure reliable performance in demanding applications like drilling, marine engineering, and defense systems. Q: What are the advantages of using tungsten alloy in counterweights? A: Tungsten alloy counterweights are compact yet highly dense, allowing precise weight distribution in limited spaces. They are widely used in elevators, cranes, robotics, and vehicles to ensure balance and stability. Q: What are the minimum order requirements for tungsten alloy products? A: Minimum order requirements vary depending on the product and customization level. As a manufacturer, we work closely with buyers to meet their needs, ensuring cost-effective solutions for small or large orders. Q: How is tungsten alloy used in medical applications? A: Tungsten alloy is used in radiation shielding for X-ray and CT scanners, as well as in medical instruments like collimators and syringes. Its high density provides effective protection while its biocompatibility ensures safety for medical use.

What I love about the tungsten jig is how fast it sinks and how naturally it moves in the water.

The tungsten jig performs great in both saltwater and freshwater; it doesn’t rust or wear out easily.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

We are looking for high-density tungsten jig for our upcoming fishing gear line. Could you please se...

Could you provide your latest price list and production capacity for tungsten heavy alloy bars? We p...

Copyright © Zhuzhou Jiuding Metal Technology Co., Ltd. All Rights Reserved