With the change in industrial technologies, China tungsten heavy alloy product price is still the material of choice for those parts that need both bulk and strength. Its high melting point and low plasticity make it an able performer during stress that is extreme and yet it remains precise in its dimensions. This is why engineers use it for making vibration absorbers, aircraft components, and kinetic energy penetrators. The coexistence of hardness and ductility guarantees a long operational lifetime, thus, making China tungsten heavy alloy product price a necessary input in high-performance engineering applications.

China tungsten heavy alloy product price is growing in use in the automotive industry as precautions in crankshaft balancing, as a damping element, and for high-performance racing components. Its dense design allows for precise control of oscillatory rotational forces to enhance vehicle stability and overall engine efficiency. The material's durability in high-temperature and stress environments serves to maximize operational performance over the lifespan of the engine.

The future development of China tungsten heavy alloy product price will concentrate on higher thermal performance and greater sustainability in applications. It is expected that new production methods will reduce carbon emissions during processing, and innovations in micro-alloying will provide higher strength and fatigue resistance. Further incorporation into next-generation nuclear reactors and fusion will also continue.

Proper operating procedures are particularly important for general durability of China tungsten heavy alloy product price. Clean regularly, preferably with soft cloths, and store in a location away from magnets or corrosive materials. Look for cracks, wear, or discolorations in surfaces periodically to ensure continued reliability and to maintain safe operating conditions.

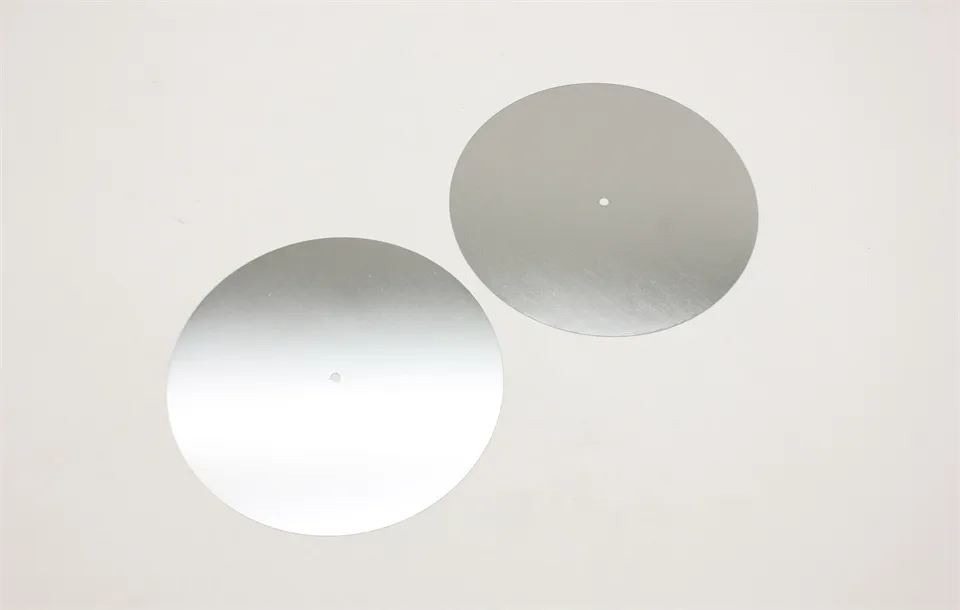

China tungsten heavy alloy product price is specifically designed for applications where there is mass that needs to fit into compact areas, while maintaining mechanical strength. It provides excellent wear resistance and thermal stability making it suitable for use as aerospace balancing parts or molds, and in heavy engineering equipment. The dense material will ensure that there is maximum efficiency and reliability in process.

Q: What makes Tungsten heavy alloy valuable in balancing applications? A: Its high density allows accurate weight adjustment in small volumes, ensuring perfect balance in rotating machinery. Q: Is Tungsten heavy alloy corrosion-resistant? A: Yes, it shows strong resistance to oxidation and chemical corrosion, even in harsh environments. Q: How does Tungsten heavy alloy contribute to medical safety? A: It is used to shield radiation without releasing harmful substances, ensuring operator and patient protection. Q: Why is Tungsten heavy alloy used in kinetic energy penetrators? A: Its density and hardness allow it to transfer energy effectively on impact, making it ideal for defense-grade applications. Q: Can Tungsten heavy alloy be recycled efficiently? A: Yes, it can be fully recycled through refining and powder recovery, maintaining material integrity.

The Tungsten heavy alloy handles extreme pressure and heat better than most metals I’ve used.

The Tungsten heavy alloy provides solid consistency in production; every piece meets our exact requirements.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

Could you provide info about your heavy-duty tungsten jig types suitable for deep-sea fishing? Looki...

We need tungsten heavy alloy plates for counterweight applications. Please share available thickness...

Copyright © Zhuzhou Jiuding Metal Technology Co., Ltd. All Rights Reserved