tungsten alloy export business manufacturer are synonymous with technological advancement and their allegiance to high-quality standards in tungsten alloy production. Their alloys have an outstandingly high compressive strength along with wear resistance. A meticulous inspection is conducted of each batch for hardness, surface finish, and internal density. tungsten alloy export business manufacturer continue to be the go-to supplier for the aerospace and defense sectors' demanding applications by making available materials that are up to the mark.

tungsten alloy export business manufacturer provide tungsten heavy alloys for the defense and power sectors that need the characteristics of strength, mass, and temperature endurance. The alloys are used for kinetic energy penetrators, vibration reduction parts, and rotor balancing. tungsten alloy export business manufacturer make it certain that every item adheres to the high-quality standards, thus supporting superior mechanical dependence within the dynamic and critical systems.

The tungsten alloy export business manufacturer will be able to push the development frontiers of Tungsten Heavy Alloys into the areas of the electric car and fusion energy industries thanks to technological improvements. Better machining, even distribution of density, and greater resistance to recurrent stress will make the material more usable. Moreover, constant R&D funding will guarantee the manufacturers’ presence in the global advanced materials market as an important player.

The proper treatment of tungsten alloy export business manufacturer products guarantees that they will perform well and their dimensions will not change over the years. Tungsten heavy alloys are to be kept under dry conditions to stop the process of surface oxidation or corrosion. Cleaning very often with mild solvents gets rid of machining residue and moisture. tungsten alloy export business manufacturer suggest using protective gloves when handling the alloys, in this way the material will not only keep its precision finish and structural integrity during the entire life span but also, will not be contaminated.

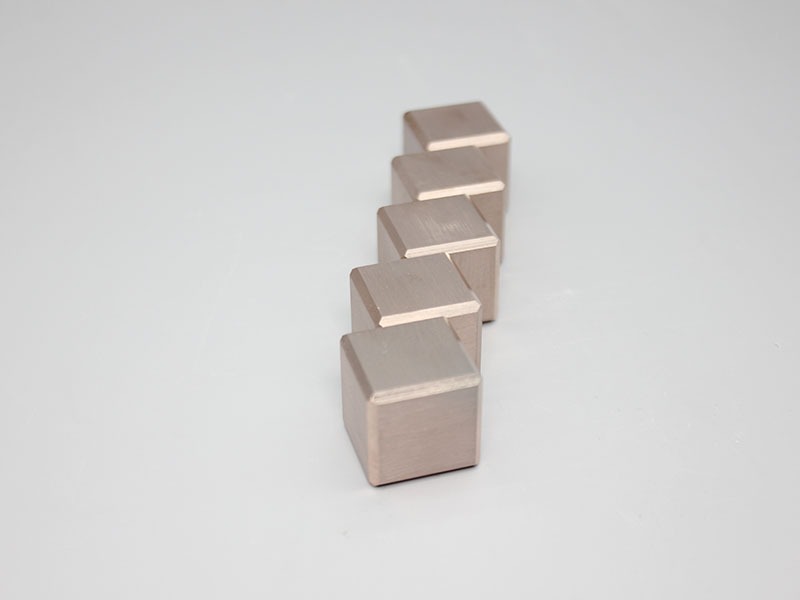

tungsten alloy export business manufacturer have made their name in the manufacturing of tungsten heavy alloys that are outstanding in terms of density and mechanical strength. These materials can endure very high mechanical stress and even corrosive environments. The professionals at tungsten alloy export business manufacturer apply cutting-edge machining and blending methods which allow them to have very precise control over the alloy's composition. These alloys are indispensable in the sectors of industrial, military, and medical equipment, which demand moderate mass and strength even under extreme conditions.

Q: What are the typical density ranges of Tungsten heavy alloy? A: It typically ranges between 17.0 and 18.8 g/cm³, providing unmatched weight and compactness for engineering designs. Q: Why is Tungsten heavy alloy used in high-impact tools? A: Its toughness and ability to resist cracking make it perfect for tools that endure strong impacts or vibration. Q: How does Tungsten heavy alloy behave in corrosive settings? A: It resists most chemical reactions, maintaining its properties in acidic or humid industrial environments. Q: What finishing methods are applied to Tungsten heavy alloy? A: Polishing and coating are often used to enhance surface quality and prevent oxidation. Q: How is Tungsten heavy alloy expected to evolve in the future? A: New manufacturing methods will focus on higher efficiency, recyclability, and improved microstructure control.

The Tungsten heavy alloy has impressive density and strength — it’s perfect for high-performance machinery.

The craftsmanship of the tungsten jig is excellent — it reacts quickly to every move of the rod.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

Could you provide your latest price list and production capacity for tungsten heavy alloy bars? We p...

We are looking for high-density tungsten jig for our upcoming fishing gear line. Could you please se...

Copyright © Zhuzhou Jiuding Metal Technology Co., Ltd. All Rights Reserved