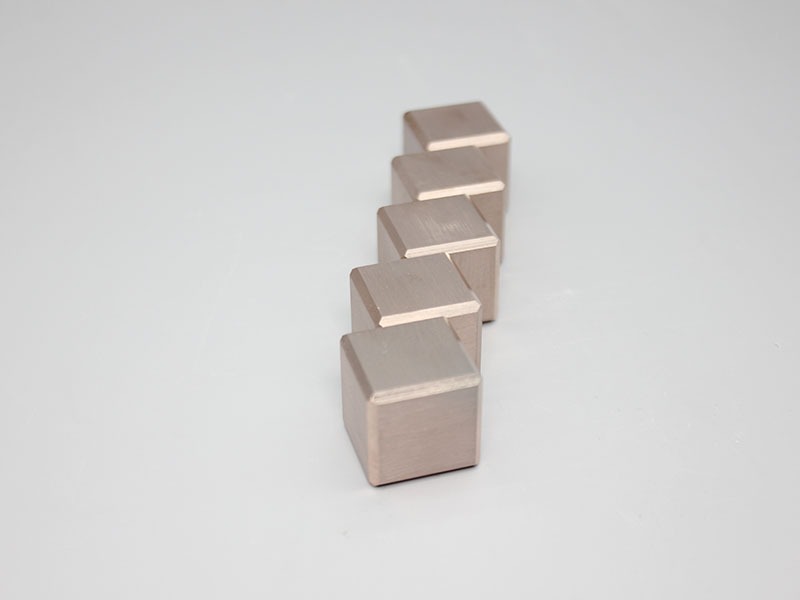

tungsten for welding stainless steel stands out among industrial materials for its combination of density, strength, and corrosion resistance. It is highly valued in industries such as aerospace, automotive, and oil and gas for its ability to perform under extreme pressures and temperatures. tungsten for welding stainless steel components are designed to endure heavy loads and harsh conditions, making them indispensable in high-stress environments. Its machinability also allows for precise customization, enabling manufacturers to meet specific application requirements. tungsten for welding stainless steel is undoubtedly a top-tier choice for industrial solutions.

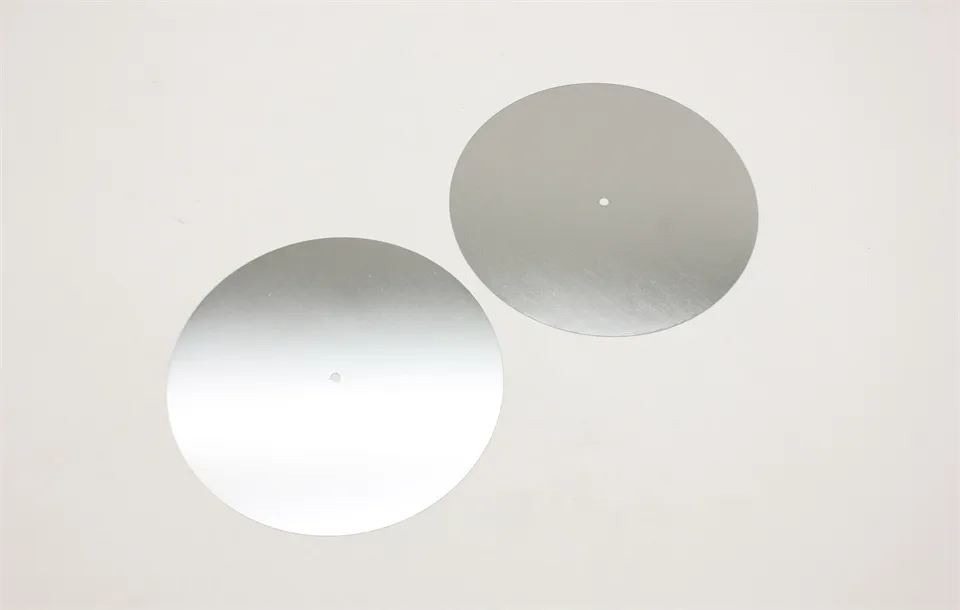

The tungsten for welding stainless steel finds wide application in electronics and semiconductor industries for heat management and electromagnetic shielding. Its thermal conductivity stabilizes high-power devices, protecting them against overheating and deformation. Parts like electrodes, contacts, and heat sinks made of tungsten for welding stainless steel ensure consistent reliability under varying temperatures. It enhances system efficiency and durability, and tungsten for welding stainless steel becomes the material of choice in precision equipment and next-generation electronic manufacturing processes.

The tungsten for welding stainless steel can be expected to trend towards higher fatigue resistance, with potential application in dynamic uses like energy absorption systems and power generation. Researchers are seeking to achieve additional grain refinement and mechanical elasticity. This will enhance service life and reduce structural fatigue in extreme industrial environments.

Proper care for tungsten for welding stainless steel ensures long-term durability. Components need to be cleaned regularly to remove dust, oil, or corrosion. It should never be exposed to acid or alkaline materials. It needs to be examined for wear, cracks, or distortion. Protective coatings and dry storage will prevent oxidation and maintain it in the best condition under repetitive mechanical loading.

tungsten for welding stainless steel is not only known for its performance but also for its eco-friendly characteristics. Unlike lead, which poses significant environmental hazards, tungsten for welding stainless steel is non-toxic and recyclable. Its use in industries like fishing, where tungsten for welding stainless steel weights replace traditional lead, helps reduce environmental contamination. Furthermore, tungsten for welding stainless steel’s durability ensures a longer product lifespan, reducing the need for frequent replacements. Choosing tungsten for welding stainless steel products contributes to sustainability efforts while meeting high-performance standards. For companies aiming to align with green initiatives, tungsten for welding stainless steel provides a reliable and environmentally conscious solution.

Q: What are the environmental benefits of tungsten alloy? A: Tungsten alloy is recyclable and non-toxic, making it a sustainable choice. Its use as a replacement for lead and other hazardous materials helps industries reduce environmental impact while maintaining high performance. Q: How does tungsten alloy perform under extreme conditions? A: Tungsten alloy excels in high-temperature, high-pressure, and corrosive environments. Its superior mechanical properties ensure reliable performance in demanding applications like drilling, marine engineering, and defense systems. Q: What are the advantages of using tungsten alloy in counterweights? A: Tungsten alloy counterweights are compact yet highly dense, allowing precise weight distribution in limited spaces. They are widely used in elevators, cranes, robotics, and vehicles to ensure balance and stability. Q: What are the minimum order requirements for tungsten alloy products? A: Minimum order requirements vary depending on the product and customization level. As a manufacturer, we work closely with buyers to meet their needs, ensuring cost-effective solutions for small or large orders. Q: How is tungsten alloy used in medical applications? A: Tungsten alloy is used in radiation shielding for X-ray and CT scanners, as well as in medical instruments like collimators and syringes. Its high density provides effective protection while its biocompatibility ensures safety for medical use.

The tungsten jig performs great in both saltwater and freshwater; it doesn’t rust or wear out easily.

The craftsmanship of the tungsten jig is excellent — it reacts quickly to every move of the rod.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

We are looking for high-density tungsten jig for our upcoming fishing gear line. Could you please se...

Do you provide OEM service for tungsten jig? We’d like to customize colors and hook types for our ...

Copyright © Zhuzhou Jiuding Metal Technology Co., Ltd. All Rights Reserved